Welder Qualification Test- 6G

In this article, we break out the steps to pass the 6G Welding Position/ Welder Test according to AWS B2.1 6G using E6010 for open root and E7018 for fill and cap for the pipe welding certification. 6G Welder Test is a Test for highly skilled welders.

6G Welding Position is a test position used for the welder performance qualification test (WQT). This welding position is covered in AWS D1.1 and ASME Section IX -welder performance qualification (WPQ) pipe welding certification.

As per ASME Section IX, Table QW-461.9, Qualification in the inclined fixed position which is 6G, shall qualify for all positions welding. So, welding a pipe in the 6G position covers all of the pipe welding as well as plate welding positions.

Related Reading: Learn Pipe Welding Positions using Welding Positions Chart

The 6G Test for Welder performance qualification is a tough test that requires skilled training, practice, and an understanding of welding techniques in depth. But, we have seen many new welders do perfect jobs and pass their certification on the first attempt.

So, what are you waiting for? Continue to upgrade yourself.

What is the 6G Welder Test?

A 6G Welding Test is a Welder Qualification Test carried out by welding a Pipe Test Coupon in a special welding position arrangement. In a 6G welder Test, the welder is qualified to perform welding in all Welding Positions. 6G Welder Test is quite difficult and it makes 6G welders high in demand for their welding skills in the USA & Canada.

Most of the pipeliners are qualified using either a 6G Welder Test or a 5G welder Test.

So, What is a 6G Pipe Welding Test?

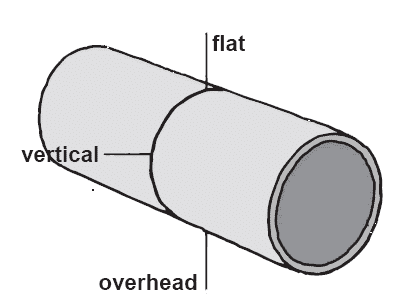

The arrangement of a 6G WQT at 45°is represented in the above picture. A fixed position means that once welding begins, the pipe cannot be rolled or moved. The welder has to weld all around the pipe in the same position.

So, it basically covers flat, horizontal, vertical welding, and overhead in a single position. Hence considered one of the tough weld tests.

Why 6G test is so versatile?

The welder qualification is based on either a tubular product (e.g. tube or pipe) or a non-tubular product (such as a plate). Here, structural welding mostly uses plates and they are easy to perform because they are performed either in a flat or vertical, or horizontal position. The welder usually maintains the same rod angle & weld position.

On the other hand, in pipe welding e.g. a 6G welding position used for the 6G welder Test, the welder has to move rod angle and weld flat, horizontal, vertical (uphill & downhill) & overhead. So, welding in the 6G position, the welder weld in all positions making 6G welding a versatile weld position. Due to this reason, codes consider and permit 6G welding positions to qualify for all welding positions.

Where to start before you go for a 6G Welder Test?

Before moving to 6G pipe welding, it’s always better to first master the plate or structural welding. Once, you got confidence in structural welding, go for pipe welding in 2G, then 5G and then practice the 6G Welding Test.

If you follow this, you will find the 6G Welder test much easier. Otherwise, you will struggle a lot.

AWS B2.1 SMAW 6G Pipe Welding Test Setup

The main welding variables as per ASME Section IX or AWS D1.1 for WQT are:

- Welding Process: SMAW (Stick Welding)

- Base material: ASTM A106, Sch. 40 Pipe, 0.28” thick, P No. 1.

- Joint Details: 1/16” to 1/8” root gap, Single V, 60 Degree included angle, without backing

- Welding Polarity: Direct Current Electrode Positive (DCEP)

- Test Position: 6G Fixed Position, vertical uphill-downhill progression.

- Welding electrode: E6010 for root run and E7018 for fill & cap passes, F No. 1.

- Welding electrode: 1/8” for root run, 3/32 for fill & capping

Steps to pass 6G test

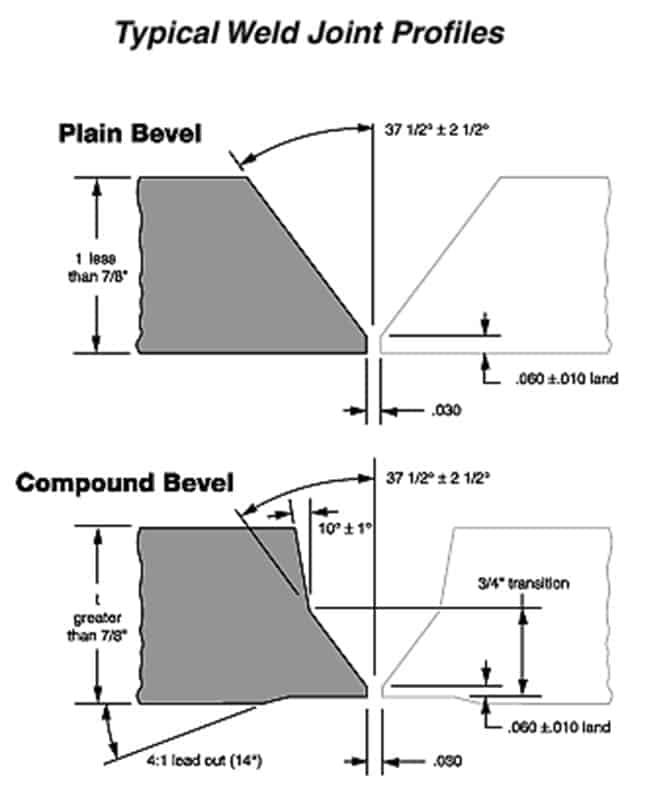

Test coupon preparation and beveling

Prepare the test coupon bevel very carefully. A right bevel and root face are very important for good uniform full root penetration. Bevel can be prepared using a gas cutter, beveling machine, or even with a grinder. The below figure shows a typical weld bevel for a 6G Welder test coupon.

Open Root Pipe Welding Techniques for the weld test

E6010 is a cellulose-type SMAW electrode. The arc of E6010 is very strong and there is no slag. A welding current of 60 amp to 75 amp is well suited for welding root run using a 3/32’’ E6010 electrode.

Watch the below video to learn about the technique for full penetration open root welding using the E6010 electrode.

Grinding during root run is recommended to make a good starting point where the welding was stopped.

Hot Pass Pipe Welding Technique

The hot pass is the weld pass welded as the 2nd to 3rd weld pass on the pipe after the root run welding. Hot pass is an important part of successful welding. Care must be taken to ensure smooth and flat weld beads as convex weld beads can give rise to slag inclusion/ sidewall lack of fusion.

Hot pass or fill pass welding is done using an E7018 type electrode which is a low hydrogen electrode. Hot pass welding can be carried out using 1/8’’ or 5/32’’ electrode diameter.

Avoiding grinding during a hot pass is recommended as many welding inspectors don’t allow grinding during hot and fill passes to judge the quality of the welders.

Pipe Welding Techniques for The Capping passes

Capping pass require usually weaving as the width of the weld increase on the top of the bevel. Maximum 3 times of the electrode diameter weaving is allowed as per ASME Section IX and AWS D1.1.

Capping can be made with multipass welding using stringer beads although it requires very good welding skills to blend the passes for a good appearance weld.

Tips for welding the capping runs

- Make sure to fuse the bevel’s edge on both sides by pushing the toe of the weld into it. This technique will eliminate the welding undercut issues.

- Follow a weld bead overlap of 25% to 50% for multipass welds during capping. Target for an even weld profile in capping. Use either stringer beads or weaving beads that suit best to you.

- Keep your hand steady with forwarding movement only.

- Avoid high welding amperage when welding for the 3 O’Clock – 9 O’Clock position. As this welding will be similar to overhead welding and molten pool tends to flow down due to gravity, it can result in excessive weld metal reinforcement.

Visual Inspection of the finished weld

- The weld shall be free from any arc strike near the weld on the pipe surface. Arc strike means welders lack good welding start practice. Usually, arc strikes are made inside the weld bevel or the previous weld so they become part of the weld.

- Clean the root from spatters for a good root profile view. The root shall be free from lack of penetration, excessive root penetration, suck back and lack of fusion, etc.

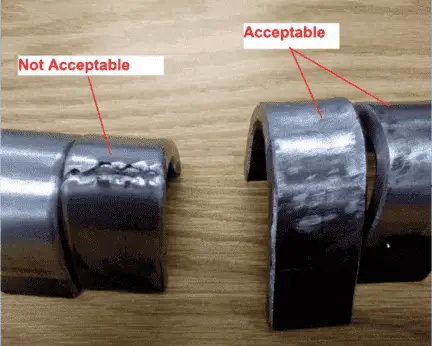

- The final finished face weld should show good workmanship with a uniform weld profile, and no undercut or spatters. Minor undercuts in small lengths can be accepted.

- The weld face reinforcement shall not be excessively high. Usually maximum of 4 mm is acceptable.

NDT or Bend testing of the test coupons:

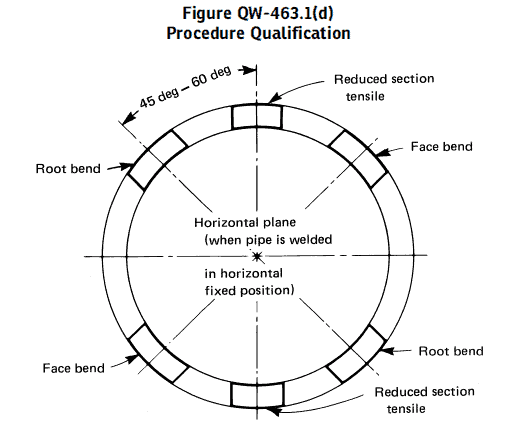

To finally certify a welder, the welder test coupon must pass a volumetric NDT such as RT or UT or can be substituted by a bend test as permitted in ASME Section IX or AWS D1.1.

The bend test shall be removed as shown in the below figure.

Click here to learn about What is Bend Testing & the types of bend tests.

Conclusion

In conclusion, the 6G welding position test is a critical evaluation that welders must pass in order to be certified. The test is challenging, but with practice and preparation, it can be successfully completed.

By passing the 6G Welding Position test, you are demonstrating that you have the skills and knowledge necessary to weld pipe safely and effectively.

Similar Posts: