Why you must know the differences between different welding rods?

Once you are in Welding Shop, you will find many different types of stick welding (SMAW) rods around you. Many beginners are not aware of the myriad types of welding rods, what are their properties, where you can use them, what polarity and welding amperage they require, and so on?

They want to know if they can use E6010 in place of E6011 or E6013 rod? or they can use E6010 instead of E7018 rod?

Using the right welding rod is a must to ensure sound & strong weld. It helps to choose the right welding polarity and thus gives the best welding bead profile as the wrong polarity and current setting can make welding appear ugly even with a good welder.

“This post breakdown all the most important & essential differences between E6010 vs. E6011. E6010 vs. E6013 or E6010 vs E7014/ E7018 rod. Let us go through this detailed post and find all the information that you must know.“

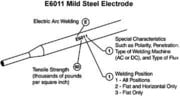

E6010 (CSA E4310) vs E6011(CSA E4311) welding rod

E6010 (CSAE4310) is a high cellulose sodium coated stick welding rod producing a high arc force to give deep welding penetration. The rod is highly suitable for welding open root runs in pipelines due to deeper penetration and no welding slag.

The usability of the rod is different than other rods like E6013 or E7018 and hence requires a lot of practice in beginning to work with the E6010 rod. E6010 is an all-position welding rod to make sound weld deposits.

E6011 (CSAE4311) is also a high cellulose rod but added with potassium instead of sodium.

Potassium makes the rod usable with AC polarity while having sodium in the coating, it can only be used with DCEP polarity. Here, sodium & potassium are arc stabilizers & potassium is more ionization potential than sodium.

FAQ: So, if you know the coating element you can also know which polarity it can run- a small thing but important, no one will tell you.

Let us first see the similarities between these two rods & then follow with the differences between E6010 (CSAE4310) vs E6011(CSAE4311) welding rods.

Similarities between E6010 (E4310) & E6011 (E4311)

| Similarities between E6010 (E4310) & E6011 (E4311) |

| Rod properties | E6010 | E6011 |

| Tensile strength (Ksi) | 60 Ksi ( 430 Mpa) | 60 Ksi ( 430 Mpa) |

| Yield Strength (Ksi) | 48 Ksi ( 330 Mpa) | 48 Ksi ( 330 Mpa) |

| Weld toughness | 20 ft·lbf @ –20°F (27 J @ –30°C) | 20 ft·lbf @ –20°F (27 J @ –30°C) |

| Chemical composition | Both have same chemistry. | Both have same chemistry. |

| Welding position | Flat, horizontal, vertical & overhead | Flat, horizontal, vertical & overhead |

| Welding arc type | High force spray arc | High force spray arc |

| Weld penetration | Deep penetration | Deep but less than E6010 |

| Baking requirements | No baking required | No baking required |

| Welding slag | thin, friable slag, easy to remove | thin, friable slag, difficult to remove |

| Uses | Root run welding, good penetration on rusty, paint, and dirty surface | Root run welding, good penetration on rusty, paint, and dirty surface |

Differences between E6010 (E4310) & E6011 (E4311)

| E6010 | E6011 | |

| Electrode coating type | High cellulose sodium | High cellulose potassium, with added calcium |

| Welding polarity | DCEP | DCEP & AC |

| Arc stabilizing element | Sodium | Potassium |

| Weld deposition | High | Low compare to E6010 |

| ISO 2560 classification | E35xC21 | E35xC11 |

| CSA W48-01 classification | E4310 | E4311 |

What is the difference between E6010 & E6011 welding polarity- current?

E6010 welding rod is used with direct current electrode positive or DCEP polarity while the E6011 rod can be used with both alternating current (AC) and DCEP polarity.

E6011 coating is mixed with potassium as an arc stabilizer element. And potassium having a larger atom size compared to sodium is good for current transfer (reason potassium loses its electrons easily), the arc starting and maintaining it easy with E6011 rod.

With the above, E6011 can be used with cheaper welding transformers while E6010 requires a costly welding rectifier or other advanced welders.

What are the differences between E6010 & E6011 rod covering or coating?

E6010 rod covering is mainly made of cellulose ( e.g. paper) which accounts for more than 30% of coating weight.

The coating was also added with deoxidizers (e.g. ferromanganese) titanium dioxide for arc stabilization & arc initiation and binding elements (e.g. aluminum or magnesium or sodium silicate) to hold the coating on the bare mild steel wire.

E6011 rod covering is also a high cellulose coating with added potassium for arc stabilization and ease in arc initiation.

E6010 is also added with the same elements that are added to E6010 and described above. In addition to that E6011 covering also contains potassium and calcium compounds in minor quantities.

E6010 & E6011 slag properties

E6010 is an all-position welding rod used mainly for pipeline root run welding due to its slag characteristics.

The slag formed by E6010 is very light & thin, friable, and less laborious. During visual, you will notice that slag does not completely envelop the weld as we see in other welding rods e.g. E6013 or E7018. Both rods produce high spatters although due to concentrated arc force.

E6011 also produces similar slag properties like E6010 rod. But the removal of E6011 slag is more laborious. The appearance of slag and weld made with E6011 is similar to the E6010 welding rod.

Which rod gives deep welding penetration in E6010 or E6011?

Both E6010 and E6011 are deep penetrating welding rods. The reason for this is the cellulose in the coating that releases a high level of hydrogen gas during burning.

On one side hydrogen is bad for carbon steel welding as it can produce delayed (Cold cracking) but on the other hand, hydrogen gives a very concentrated welding arc, and hence arc is able to penetrate deeper.

That’s why E6010 & E6011 rods can be used to weld on rusty, painted surfaces.

And if we increase the welding current, they can cut the materials (e.g. cutting of stainless steel or carbon steel on-site when cutting tools are not available).

E6010 vs. E6011, which is the best rod?

Both E6010 and E6011 are mild steel high cellulose stick welding rods used for welding mild steel, carbon steel, galvanized steel, and sheet metals gauge sheets.

E6010 is mostly used for welding pipelines root run in oil & gas and other applications as it gives deeper penetration than E6011.

Can E6011 be used in place of E6010

Both rods can be used on rusty, painted, or oily surfaces. Overall, E6010 is preferred over E6011 by welders.

But E6011 is also a good rod as it gives good arc stability and can also be used with alternating current. So, if you have only a welding transformer, then go for E6011.

CLICK TO WATCH HOW TO WELD PIPE ROOT RUN WITH E6010 ROD

6010 vs 8010 welding rod

Both E6010 and E8010 (actual classification is E8010-P1) are high cellulose stick welding rods.

While E6010 is used for welding mild steel, galvanized steel, and low carbon steel, E8010 is used for welding high strength steel. E8010 tensile strength is 80Ksi while E6010 is 60 Ksi only.

Click the below post to learn more about the E8010 (E8010-P1 or E8010-G) stick welding rod in detail.

What type of coating is E7018 Welding Rod?

E7018 rod has low hydrogen type coating. Check this article for more details- https://www.materialwelding.com/welding-electrodes-coating-types/

Can we use E6010 with DCEN polarity?