What is E6011 (E4311) Electrode & its meaning

E6011 Rod is a carbon steel (mild steel) welding rod for stick welding. E6011 [E4311 as per CSA W48] electrodes are designed to be used with AC current polarity and to duplicate the usability characteristics and mechanical properties of the E6010 classification.

E6011 can also be used with DCEP (electrode positive). E6011 gives less penetration compared to the E6010 welding electrodes.

Arc action, slag, and fillet weld appearance are similar to those of the E6011 electrodes.

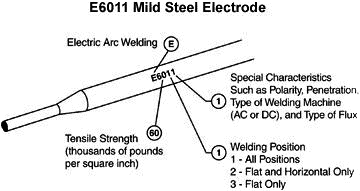

E6011 Welding Electrode Meaning

E6011 electrode is meant for mild steel welding. The meaning of the E6011 (E4311) welding electrode is:

- ‘E‘ Means ‘Electrode’ for stick welding,

- ‘60′ mean ’60 Ksi electrode tensile strength‘.

- ‘1′ at third digit means the welding electrode to be used ‘for all positions’.

- ‘1′ at fourth digit refer to ‘electrode characteristics‘ as per SFA 5.1.

E6011 Welding Rod Specifications

E6011 welding rod specifications are AWS A5.1 or ASME Section IIC SFA 5.1. The chemical and mechanical properties are specified in AWS A 5.1 specification.

E6011 is the electrode classification while A 5.1 is the electrode specification. CSA 48-18 equivalent of E6011 is E4311.

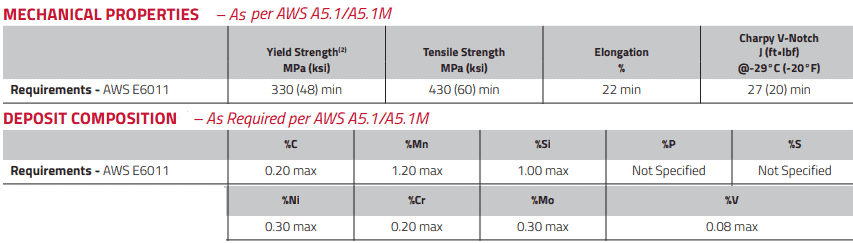

E6011 Chemical and Mechanical Properties

The chemical and mechanical properties of the E6011 rod are given in the below table.

The tensile strength of E6011 is 60 Ksi or 430 MPa minimum, Yield is 48Ksi or 330 MPa with a minimum elongation of 22 %.

The toughness of E6011 is 30 ft. lbs. (tested at -20°F) or [20 J at –30°C].

E6011 Covering Type

The covering of E6011 rods is high in cellulose. The coating type for the E6011 rod is high-cellulose potassium. Generally, the coating also contains calcium & potassium in small amounts.

The main covering elements in E6011 welding rods are:

- Cellulose pulp (cellulose covering element)

- Sodium silicate (Covering binder)

- Magnesium oxide (Oxidizer)

- Titanium dioxide (Oxidizer)

- Quartz

- Calcium carbonate (to produce welding gases)

The coating is similar to the E6010 welding electrode but with additional coating elements of Potassium instead of sodium coating.

The amount of cellulose is also kept lower side compared to the E6010 electrode, thus the E6011 arc is having less force compared to the E6010 electrode which has high cellulose elements in the coating.

Drying (Baking) and Storage of E6011 Rod

Drying or Baking of E6011 is not recommended due to cellulose coating. If the E6011 is baked or re-dried, the rod moisture will be out and coating will be no more effective.

The storage of E6011 shall be at ambient temperature and does not require any holding oven unless working at low-temperature areas.

Most of the E6011 electrodes are used as it is after opening the packet. Unused electrodes shall be kept in the same packet or designated storage area to prevent damage to the electrode coating.

Cellulosic coverings of E6011 [E4311 as per CSA W48] electrodes need moisture levels of approximately 3% to 7% for proper operation; therefore, storage or conditioning above ambient temperature may dry them too much and adversely affect their welding operation characteristics.

E6010 Electrode Specification & its meaning

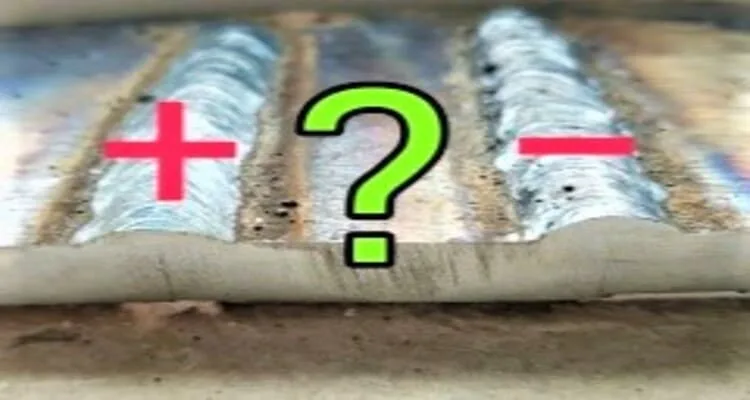

E6011 Polarity

E6011 electrode can be used with AC (Alternating current) or DCEP (Direct current electrode positive) polarity. Potassium present in the coating makes it easy to use with DCEP polarity.

E6011 does not have any sodium so it can not be used with DCEN (Direct current electrode negative) polarity.

Related reading: Types of polarity in SMAW, MIG, MAG, FCAW, TIG and SAW

E6011 (E4311) Welding Rod Amperage Chart

E6011 (E4311) electrode can be run easily with low current due to its good arc start ability. The arc of E6011 is smooth and less penetrating compared to E6010.

When welding with E6011 diameter 3/32-inch or 2.5 mm welding current of 40 to 80 ampere is used. For 5/32, 3/16 inch rod recommended welding amperage is shown in the below table.

6010 vs. 6011 Welding Rod

Both 6010 and 6011 are high cellulose coating electrode but main difference is that E6011 coating is having additional Potassium added along with Sodium.

Check out below table for complete details.

| Rod Characteristics | E6011 | E6010 |

|---|---|---|

| AWS Specification | AWS A5.1 | AWS A5.1 |

| Classification | E6011 | E6010 |

| Coating types | High Cellulose Sodium & Potassium | High Cellulose Sodium |

| Tensile & Yield Strength (Ksi) | 60 & 48 | 60 & 48 |

| Polarity | AC, DCEP | DCEP only |

| Welding Position | All | All |

| Weld penetration | Deep | Deep |

| Slag | Light, fragile slag |

thin, fragile slag |

| Arc features | forced spray arc | High Force spray arc |

| Application | Root & hot pass, welding on rusty, dirty, painted surface | Root & hot pass, welding on rusty, dirty, painted surface |

E6011 vs. E6013

Both E6011 and E6013 rod are mild steel welding rods. The difference between E6011 and E6013 is the coating types.

| Rod Characteristics | E6011 | E6013 |

|---|---|---|

| AWS Specification | AWS A5.1 | AWS A5.1 |

| Classification | E6011 | E6013 |

| Coating types | High Cellulose Sodium & Potassium | High titania potassium |

| Tensile & Yield Strength (Ksi) | 60 & 48 | 60 & 48 |

| Polarity | AC, DCEP | AC, DCEN & DCEP |

| Welding Position | All | All |

| Weld penetration | Deep | low |

| Slag | Light, fragile slag |

light & easily removable |

| Arc features | Force spray arc | stable smooth arc |

| Application | Root & hot pass, welding on rusty, dirty, painted surface; cap passes | best for sheet metal welding |

E6013 electrodes have low penetrating power, fast freezing slag and this may result in incomplete penetration in fillet welded joints while E6011 gives better penetration than the E6013 type. E6011 runs with AC & DCEP while E6013 can be run with AC, DCEP, and DCEN Polarity.

E6011 welding rod uses

E6011 welding rods uses for a variety of purposes. They are commonly used for general-purpose welding, such as on mild steel, carbon steel and low-alloy steels to carbon steel welding.

- They can also be used for root passes on thicker materials, as well as fill and cap passes.

- E6011 welding rods have a smooth arc that is easy to control, making them ideal for beginners or those who are new to welding. The rod also produces minimal spatter, which makes cleanup easier.

- E6011 welding rods are easy to use and provide good penetration into the metal being welded. They can be used in all positions, including vertical and overhead.

- E6011 welding rods are available in a variety of sizes and can be purchased from most welding supply stores.

6011 vs 7018

6011 is a High Cellulose Covering welding rod like E6010 but E6011 can be used with AC & DCEP Polarity (E6010 only for DCEP). 7018 is a low hydrogen potassium covering while E6011 covering is made of Sodium and potassium.

The main differences between 6011 vs 7018 welding rod are listed in below table:

| Rod Characteristics | E7018 | E6011 |

|---|---|---|

| AWS Specification | AWS A5.1 | AWS A5.1 |

| Classification | E7018 | E6011 |

| Coating types | Low hydrogen Potassium with added Iron Powder | High Cellulose Sodium & Potassium |

| Tensile & Yield Strength (Ksi) | 70 & 58 | 60 & 48 |

| Polarity | AC, DCEP | AC, DCEP only |

| Welding Position | All | All |

| Weld penetration | Medium | Deep |

| Slag | Thick slag |

Light, fragile slag |

| Arc features | Smooth arc | Force spray arc |

| Application | Fillet, fill & cap passes | Root & hot pass, welding on rusty, dirty, painted surface |

Similar Posts:

- How to Choose the Right Stick Welding Electrode and Rod Type

- E7018-1 or E4918-1-H4 electrode specification, meaning, chemical & mechanical properties with MTC

- E8018-B2 electrode specification and meaning

- E7024, E7024-1 Electrode Specification & its meaning

- E6013 Electrode Specification & its meaning, actual MTC