Meaning of E7024 Welding Rod

E7024 welding electrode as per AWS A 5.1 or E4924 as per SFA 5.1M/ CSA W48 is a rutile coating (titania oxide) with extra added iron powder making it a heavy coated electrode for high deposition rates on horizontal and down hand welding.

E7024 electrode coverings contain large amounts of iron powder in combination with ingredients similar to those used in E6012 and E6013 (E4312 and E4313) stick welding electrodes.

The coverings on E7024 (E4924) electrodes are quite thick (Compared to other stick welding rods) & is roughly about 50% of the total weight of the welding rod.

This gives a very high weld deposition efficiency when welding with E7024 rod. This electrode is highly suited for making fillet welds in flat positions & used widely in oil & gas tank bottom plate welding, fillet welds in shipyards, and structural work in building & bridges.

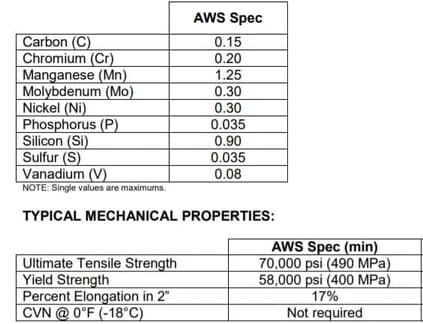

Chemical and mechanical properties of E7024 rod

The chemical and mechanical properties of the E7024 ( CSA E4924) stick welding rod are given in the below table.

The tensile strength of E7024 ( CSA E4924) is 70 KSi (490 MPa), yield strength is 58 Ksi (400 MPa). The maximum carbon content in E7024 ( CSA E4924) is 0.15.

Covering type of E7024 Electrode

E7024 is a rutile coating (titania oxide) with extra added iron powder. These electrodes are very thick compared to E6010, E6013, or E7018, etc. The covering weight is usually 50% of the total electrode weight.

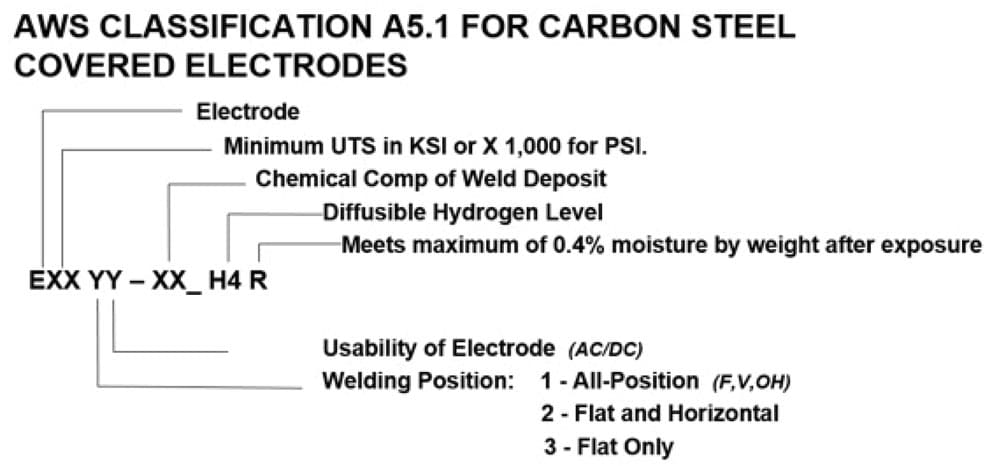

E7024 Electrode/ Rod Specification and Classification

E7024 Welding rod is has classification as per ASME Section IIC, 5.1. The CSA equivalent of E7024 is E4924 as per CSA W48 or SFA 5.1M.

Like other stick welding electrodes, every digit in the E7024 electrode has their own meaning. These digits give very valuable information about this electrode as given below:

- E means Electrodes.

- The next two letters i.e. ’70’ shows the weld tensile i.e. 70 KSI or 70000psi. And,

- The next letters ‘2’ means the rod is useable for Horizontal- Fillet and flat position welding.

- The last letter ‘4’ indicates it is a Iron powder, titania oxide and can be welded with AC, DCEN, and DCEP polarity.

Click here to Learn Types of Polarity in Welding.

Charpy V-Notch Impact (toughness) Requirements for E7024 type electrode

E7024-type electrodes don’t have any toughness requirements.

E7024-1 types require welding electrodes to have minimum V-Notch toughness values of 20 ft·lbf at –0°F [27 J at –20°C].

E7024 Welding electrode Polarity

E7024 type electrodes are can be used with DCEP, DCEN & AC polarity

Storage & Baking/ reconditioning of E7024 Electrode

Redry the E7024 electrode at 275°F ± 25°F [135°C ± 15°C] for 1 hour at temperature. Holding of the E7024 electrode is to be ensured at 20°F to 40°F [10°C to 20°C] above ambient temperature.

Maximum of 50% relative humidity is recommended for electrode storage or when exposed to ambient air.

E7024 vs E7018 low hydrogen Electrode

E 7024 stick welding rods are not suitable for welding in all positions, as the digit ‘2’ in rod classification indicates, this is good for welding in horizontal and flat/plane positions while E7018 is all position electrodes.

E7018 is low hydrogen potassium-based coating while E7024 is a rutile titania coating. Click here to learn deep about the E7018 electrodes.

Also, in the ASME section 9, F-numbers for these electrodes are different. On one hand, E-7024 has a Rutile iron powder type covering and has F No. 1.

This is not a low hydrogen electrode but a rutile type. While E-7018 classification is Low hydrogen coating with added potassium & iron powder that has F no. 4.

The similarities between E7018 & E7024 are:

- Both are having iron powder coating.

- Both have 70ksi minimum tensile strength

Selection of current for E7024 Electrode

Recommended Welding Parameters for E7024 electrodes are given in the below table based on electrode diameter.

| Recommended Welding amperage for E7024 electrodes | |

| Rod dia. | Amperage |

| 1/8″ | 90 – 140 |

| 5/32″ | 120 – 180 |

| 3/16″ | 190– 240 |

Characteristics of E7024 Type electrode

- E7024 Coating type is an iron powder with added titania and used in flat & horizontal fillet welding for tanks, shipbuilding & structures to give a high weld deposit.

- Gives high weld deposit efficiency for single-pass welding runs.

- Easy slag detachment properties.

7024 Welding Rod Uses

7024 welding rod uses are mainly for welding high deposition welds in flat and horizontal welding position. 7024 welding rod is mainly used for welding Fillet welds.

Most of welding is shipyard and structural welding is carried out using 7024 welding rod where weld type is predominately Fillet weld.

7024 welding rod provides high weld output, very low welding spatters, a smooth welding arc with low weld penetration.

The eE7024 electrode can be used in welding of fillet welds in flat or horizontal weld positions only. welding on groove weld will results in issue of lack of penetration and shabby weld profile.

Similar Posts: