E7015 welding rod is a low-hydrogen, sodium covering electrode that produces exceptional X-ray quality welds in all positions. It is used for welding mild and medium-carbon steels, as well as high-strength, low-alloy steels.

E7015 has a very smooth arc with little spatter and produces an excellent bead appearance. It can be used with DC power only (reverse polarity), making it a versatile electrode for use in all welding applications.

Compared to E7018, E7015 rods provides better penetration and less slag and hence it is beneficial for pipeline root welding.

E7015 Electrode Chemical and Mechanical Properties

| Element | Range |

|---|---|

| Carbon |

0.15% Max. |

| Manganese | 1.25% Max. |

| Silicon | 0.9% Max. |

| Phosphorus | 0.035% Max. |

| Sulfur | 0.035% Max. |

| Nickel | 0.30% Max. |

| Chromium | 0.20% Max. |

| Molybdenum | 0.30% Max. |

| Vanadium | 0.08% Max. |

| Mn+Ni+Cr+Mo+V total, | 1.50% Max. |

| Properties | Value |

|---|---|

| Tensile Strength, Ksi (MPa) | 70, (490) |

| Yield Strength, Ksi (MPa) |

58 (400) |

| Elongation, % minimum | 22 |

| Toughness | 20 ft·lbf at –20°F (27J at-30°C) |

E7015 Electrode Specification

E7015 electrode specification is AWS A5.1 and it is a low hydrogen electrode. This electrode can be used for all position welding except vertical down.

E7015 is suitable for carbon steels, low alloy steels, and some high-strength steels. This electrode provides good operator appeal because of its easy slag removal and good re-ignition characteristics. The deposited metal has good mechanical properties with low hydrogen content.

E7015 Welding Rod meaning

If you’re a welder, then you know that there are different types of welding rods out there. But what does the E7015 welding rod mean?

- The “E” in E7015 stands for the Electrode.

- The “70” means tensile strength in Ksi (thousand pounds per square inch).

- The “1” means that it can be used in all positions.

- The “5” shows the electrode’s characteristics.

So, what does this all mean for you as a welder? Basically, if you’re looking for a welding rod that can be used in all positions and has high tensile strength, then the E7015 is the perfect choice for you.

E7015 vs E7018

E7015 vs E7018 electrodes are both low hydrogen electrodes. The main difference between the two is that E7015 has a sodium coating, while E7018 has a potassium coating.

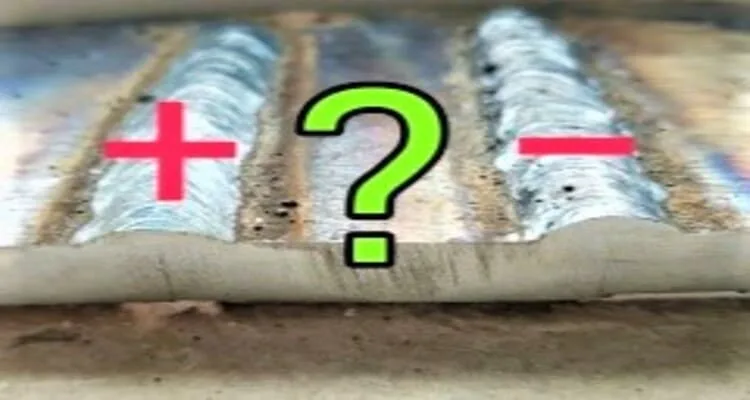

The other main difference between E7015 and E7018 electrodes is the welding polarity. E7015 can only be used with DCEP while E7018 can be used with AC and DCEP.

The below tables gives the main differences between E7015 and E7018 welding rods.

| Rod Characteristics | E7018 | E7015 |

|---|---|---|

| AWS Specification | AWS A5.1 | AWS A5.1 |

| Classification | E7018 | E7015 |

| Coating types | Low hydrogen Potassium with added Iron Powder | Low-hydrogen sodium |

| Tensile & Yield Strength (Ksi) | 70 & 58 | 70 & 58 |

| Polarity | AC, DCEP | DCEP only |

| Welding Position | All | All |

| Weld penetration | Medium | Moderately |

| Slag | Thick slag |

heavy, friable, easily removable slag |

| Arc features | Smooth arc | Moderately smooth arc |

| Application | Fillet, fill & cap passes | welding high-sulfur and enameling steels |

E7015 Welding Rod Uses

E7015 Welding Rod is an all-position, low hydrogen electrode designed for use with DCEP polarity. It can be used on a wide range of base metals, including carbon steels, low alloy steels, and high-strength steels.

E7015 Welding Rod produces a smooth, stable arc with minimal spatter and excellent weld bead appearance. It is suitable for welding in all positions, including vertical up and overhead.

E7015 Welding Rod is manufactured to strict quality standards in order to ensure consistent performance and reliable welds. All electrodes are tested in accordance with industry standards to ensure they meet the highest quality standards. E7015 Welding Rod is available in a variety of sizes and packaging options to meet the specific needs of your application.