E6012 Welding Electrode meaning

E6012 is a high titania sodium Stick Welding Rod used for welding of mild steel. E6012 has low penetrating welding arc and can be used with AC and DCEN Polarity.

The covering of E6012 welding rod is Titania/ rutile type and made of clay, feldspar, sodium silicate (for binding) and calcium compounds.

The coverings are high in titania, usually exceeding 35% by weight, and usually are referred to as the “titania” or “rutile” type. The coverings generally also contain small amounts of cellulose and ferromanganese, and various siliceous materials such as feldspar and clay with sodium silicate as a binder. Also, small amounts of certain calcium compounds may be used to produce satisfactory arc characteristics on DCEN Polarity (electrode negative).

E6012 Welding Electrode Chemical and Mechanical properties

The tensile strength of E6012 welding rod is 60 Ksi (430 MPa), yield strength 58 Ksi (330 MPa) and an elongation of 17% minimum. Toughness requirements for E6012 welding rod are not specified in AWS A5.1.

Detailed chemical & mechanical properties of E6012 Welding electrode are given in the below table:

| Element | Value |

|---|---|

| Carbon | 0.20 Max. |

| Manganese | 1.20 Max. |

| Silicon | 1.00 Max. |

| Sulfur | Not specified |

| Phosphorus | Not specified |

| Nickel | 0.30 Max. |

| Chromium | 0.20 Max. |

| Molybdenum | 0.30 Max. |

| Vanadium | 0.08 Max. |

| Property | Value |

|---|---|

| Tensile Strength | 60 Ksi (430 MPa) |

| Yield Strength | 48 Ksi (330 MPa) |

| Elongation | 17% minimum |

| Toughness | Not specified |

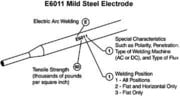

E6012 Welding Rod Specification & Classification

The Specification of E6012 Welding rod is AWS A 5.1. E6012 is the classification number for this electrode as per AWS A5.1 specification.

E6012 Welding Rod uses

E6012 welding rod is used on thin sheet metal welding due to its low penetration arc.

This is also used for welding fillet weld, corner weld and tacking for smaller thickness mild steel.

E6012 is having very smooth arc & handling, and good for gap bridging in horizontal positions.

E6012 vs E6013 Welding rod

E6012 is a titania sodium base covering rod while E6013 is titania potassium base covering.

The main difference between E6012 & E6013 is based on their flux covering. E6013 gives a easy and smooth arc with easy slag removal compare to E6012 welding rod.

| Rod Characteristics | E6012 | E6013 |

|---|---|---|

| AWS Specification | AWS A5.1 | AWS A5.1 |

| Classification | E6012 | E6013 |

| Coating types | LHigh titania sodium | High titania potassium |

| Tensile & Yield Strength (Ksi) | 60 & 48 | 60 & 48 |

| Polarity | AC, DCEN | AC, DCEN & DCEP |

| Welding Position | All | All |

| Weld penetration | Low | low |

| Slag | Thick slag |

light & easily removable |

| Arc features | Smooth arc | stable & smooth smooth arc |

| Application | sheet metal welding, gap bridging | best for sheet metal welding |

E6012 Welding Electrode Polarity & terminal

E6012 welding rod can be used for AC and DCEN Welding polarity.

E6012 Welding Rod AC or DC?

E6012 welding rod can be used with AC polarity. For DC current, E6012 can only be used with Direct Current Electrode Negative (DCEN) polarity. DCEN is also called straight polarity.

E6012 Welding Rod F-Number & A-Number

The F-Number of E6012 Welding electrode is F-Number-2. A-Number for E6012 weld deposit is 1.