What is F Number in Welding?

F Number in Welding means Filler Number, where filler is either a solid rod or coated electrode. F Number in Welding are given based on the usability characteristics (defined in ASME Section IIC, SFA 5.1 for example for carbon steel SMAW electrodes) and metallurgy of the welding filler metal in BPVC ASME Part-9 and AWS D1.1.

F Numbers are given to welding filler wire/ electrode by the ASME to a similar group of welding consumables (Welding electrode- Stick welding (SMAW), TIG, MIG, FCAW, & SAW, etc.) having akin properties & characteristics.

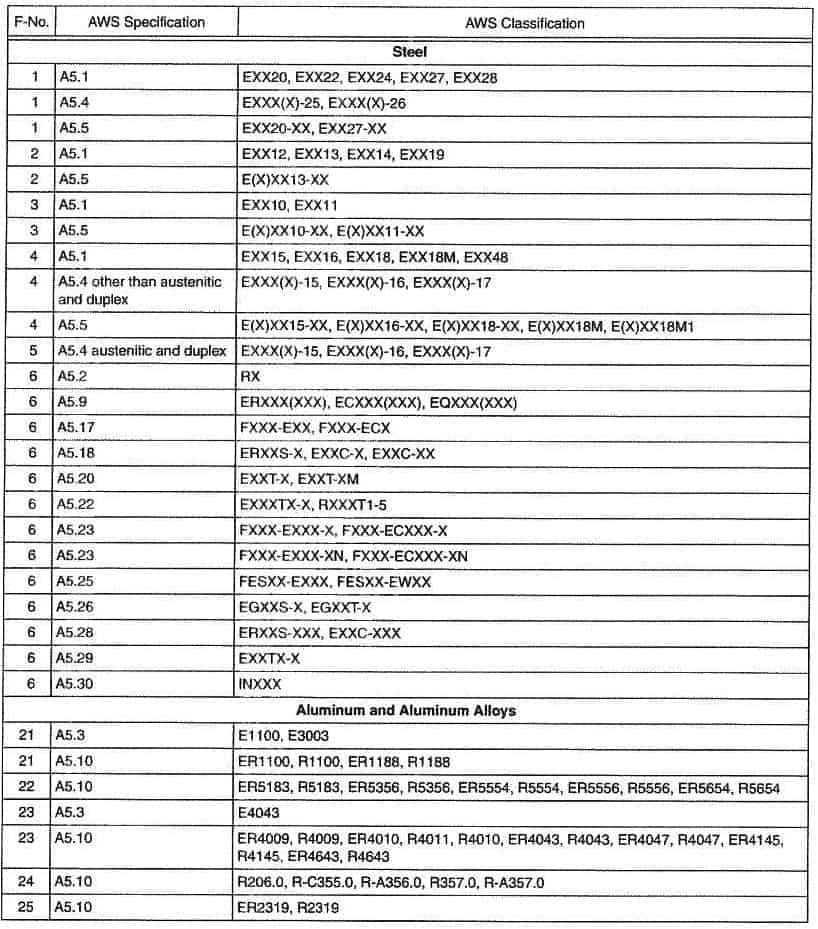

ASME Section 9, Table- QW-432 have listed the welding consumables with their respective F Number. Note that Welding electrode Classification is the standard number found on the electrode or electrode box, such as e6010, e7018, e316-15, er70s-3, or e70t-1.

F Number is Essential or Non-Essential Variable?

F Number in Welding is an essential variable for performance and procedure qualification as per ASME Section IX, AWS D series, and ISO 15614 series.

This F Numbers sorting for welding consumables (electrodes & wires) is founded on their welding properties (ease to use, coating type, type of rod, etc.), which affects the welder’s ability to produce a satisfactory & sound quality weld joint.

Read more: Essential Variables for Welder Qualification AWS D1.1 & ASME Section IX

Also, this F Number grouping, helps to minimize the quantity of WPS qualifications and welder performance qualifications (WPQ), as similar welding electrodes can be used without re-qualification, and hence a potential cost saving.

Related reading: What is A-Number in Welding & ASME?

F Number Alloy grouping

F Numbers in Welding for electrode and filler metals are grouped based on their metallurgy. The below table gives the classification based on BPVC ASME Section IX.

F Number Chart For Welding

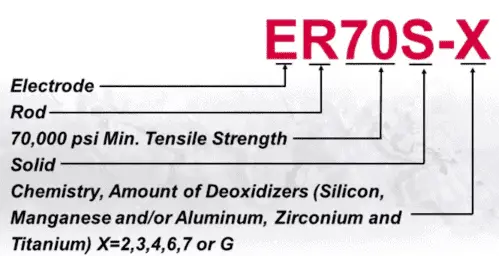

Below is the F-Number Chart for welding consumables most widely used. The F-Number for the most widely used Welding Rods are:

- F Number for E6010, E6011, E6012, E6013, E6014, E7024 is F. Number 1.

- F Number for E7015, E7016, and E7018 is F-Number 4.

- F Number for ER70S-2, ER70S-3, and ER70S-6 is F. Number 6.

- F Number for E309L, E308L, and other austenitic stainless steel welding consumables is 4.

| Welding Rod Classification | AWS Specification | F- Number | A-Number |

|---|---|---|---|

| E6010 | AWS A5.1 | F. Number 3 | 1 |

| E6011 | AWS A5.1 | F. Number 3 | 1 |

| E6012 | AWS A5.1 | F. Number 2 | 1 |

| E6013 | AWS A5.1 | F. Number 2 | 1 |

| E7015 | AWS A5.1 | F. Number 4 | 1 |

| E7016 | AWS A5.1 | F. Number 4 | 1 |

| E7018, E7018-1 | AWS A5.1 | F. Number 4 | 1 |

| E7024 | AWS A5.1 | F. Number 1 | 1 |

| ER70S-2 | AWS A5.18 | F. Number 6 | 1 |

| ER70S-3 | AWS A5.18 | F. Number 6 | 1 |

| ER70S-6 | AWS A5.18 | F. Number 6 | 1 |

| E71T-1C | AWS A5.20 | F. Number 6 | 1 |

| E7010-A1 | AWS A5.5 | F. Number 3 | 1 |

| E7018-A1 | AWS A5.5 | F. Number 4 | 2 |

F Number Chart in Welding for Carbon Steel Welding Electrodes

The F Number for Carbon steel welding electrodes and filler wire is from F-Number 1 to 6. Stick Welding rods F-Number is 1 & 4 while for Solid filler wire of Carbon steel, it is F Number 6 as given above.

F Number in Welding for Carbon steel and low alloy steel Flux Cored welding wire (FCAW wire) is also F-Number 6.

Refer to the below table for the full list of F Numbers Chart in welding.

Click here to download F-Number Chart PDF Copy.

Importance of F Number for Procedure Qualification (WPS)

F numbers for welding consumables are listed and specified for various filler metals & rods (for Stick welding (SMAW), TIG, MIG, FCAW, & SAW,- for example) in ASME Section IX- Table QW-432.

F Numbesr in Welding being an essential welding variable for procedure & performance qualification if changed that actually being used for the test, require requalification of the WPS or welder/ operator.

ASME Section IX does permit changes for non-essential variables or some specified range (For example current, voltage, preheat temperature) but For F-Number it is not allowed.

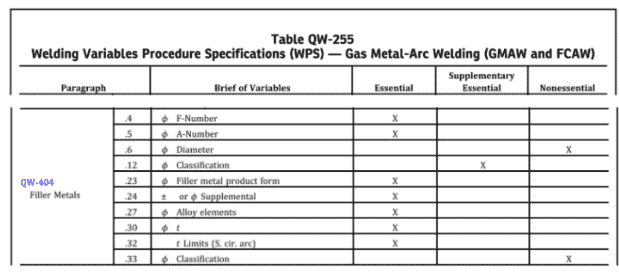

The F-numbers must be the same on WPS as used in the PQR qualification stage. Refer to the below table and you will notice that F-Number is an essential variable for procedure qualification. Although the change in electrode diameter is a non-essential variable.

Importance of F Number for Performance Qualification (WPQ)

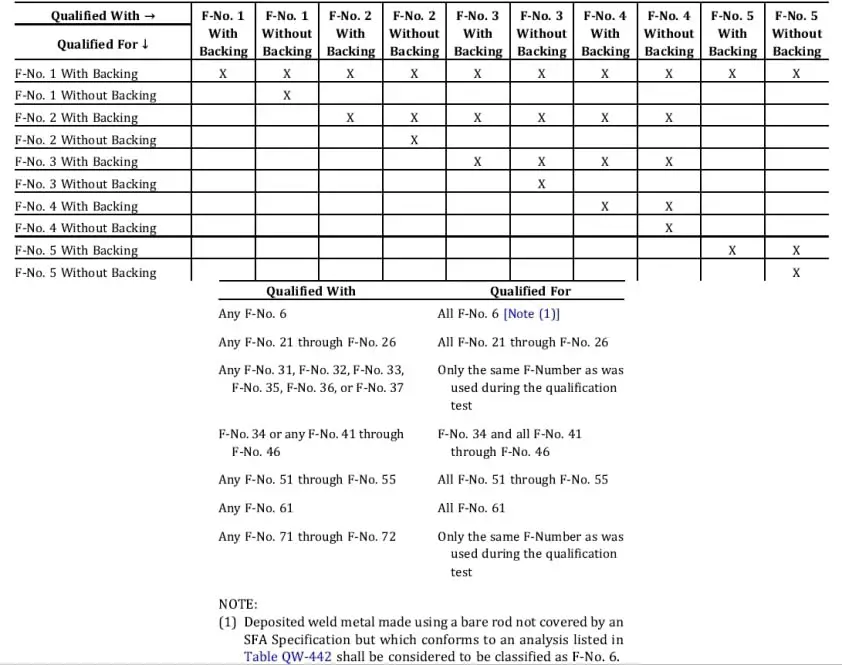

The change from one F-number to another F-number in Welding is allowed within a range for welder performance qualification in ASME section IX or AWS D1.1.

If you refer to the ASME Section 9, Article III, for welder qualification, You will find the essential welding variables applicable for welder qualification in Table QW-352 to QW 357.

In these tables, you can see that F-Number in Welding is an essential variable for welder/ welding operator WQT or performance qualification.

Table QW 352- QW 357, provides the range of F-Number used during WQT and the range qualified for F-Number in Table QW-433 (abstract given below from ASME Section IX).

Here, take an example for F-Number 3. If the welder had used F-Number 3 rod during welding, he is qualified to perform welding using F-Number 1, 2 & 3 within the conditions specified in this table. (E.g. with/ without backing).

Making a selection of an F-Numbers in Welding that covers the wide range of qualified F-Number is a wise decision that should be considered before the start of the WQT. This is essential to reduce to cost of welder qualification (WQT).

For example, using carbon steel pipe or plate material instead of using the costly stainless steel for the welder qualification test coupon.

ASME Section IX allows the qualification of P1 material (carbon steel) to qualify welder on P8 material (Stainless steel).

This ensures financial savings by using the WPS or welder for a wider range. In this way, a welder can be qualified for stainless steel (P8) by using carbon steel (P1) but as F-Number is an essential variable, the welding electrode must be used of stainless steel only.

F-Number-6 Welding Consumables/ Rod

F Number-6 (F-6) is applicable for solid welding filler rods & Flux Cored Filler wires.

The most commonly used welding rods as ER70S-2, ER70S-6, ER80S-B2, ER309L, and EM8 are having F-Number 6 (F-6).

Welding rods/ Filler wires as per AWS A5.2, A5.9, A5.17, A5.18, A5.20, A5.22, A5.23, A5.25, A5.26 to A5.30 & A5.36 welding rods have F Number-6 (F-6).

F-Number-1,-2, -3 & -4 Welding Consumables/ Rod

F Number-1 for Carbon Steel Stick (SMAW) Welding rods as per the AWS A5.1 specifications. E7020, E7022, E7024, E7027 & E7028 welding rods have F-Number-1 (F-1).

Cellulose-type welding rods such as E6010, E6011, and E8010-G types welding rods have F-Number-3 (F-3).

For rutile & acid coating type welding rods (E.g. E6012, E6013), F-Number is F-Number-2 (F-2).

ASME SFA Number chart

ASME SFA Number chart covers the welding electrode specifications. There are total 36 ASME SFA Number starting from SFA 5.01 to SFA 5.36.

ASME SFA 5.1, 5.18, 5.20 are for carbon steel welding rods. SFA 5.4 & 5.9 are for stainless steel welding rod.

Complete list of ASME SFA Number chart is given below for reference.

Click here to download complete ASME SFA Number.pdf.

Similar Posts: