What is P Number in Welding?

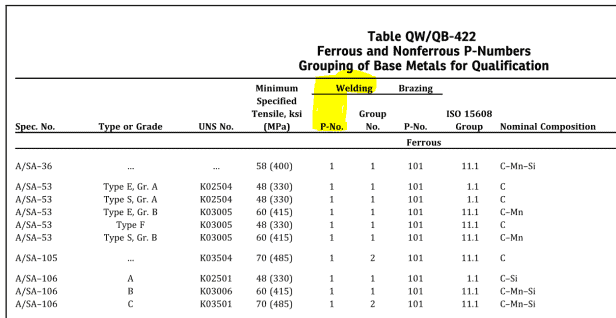

P Number (P mean Parent Metal) in ASME Section IX means the material types classification based on their chemical & mechanical characteristics. P Number is provided for users to minimize the numbers of WPS, PQR, and WQT qualifications. In ASME Section IX, Table QW/QB-422 materials are classified as:

- Ferrous Metals

- Non-Ferrous Metals

For Ferrous metals only, ASME Section IX provided Group Numbers in Table QW/QB-422. Material having Group Numbers means that they have toughness requirements.

The base metals are assigned specific P-Number based on their chemical and mechanical properties. E.g., P-Number 1 is for C-Mn (Carbon Manganese) or Low Carbon Steel materials.

P-Number is an Essential variable for Welding Procedure Qualification according to ASME Section IX.

Assignments of P-Numbers have been based on similar base metal mechanical & chemical properties, for example:

- Chemical Composition- C-Mn, C-Mo, Cr-Mo, etc.

- Ease of Welding: Ferritic, Martensitic & austenitic types.

- Ease of Brazing- Applicable for Non-ferrous materials.

- Mechanical Properties– Tensile & toughness.

One P-Number covers various grades of material specification having similar metallurgy and mechanical properties.

So, a procedure qualification made according to one of these materials under the same P-Number covers other materials having the same P-Number.

Hence, no separate procedure qualification (WPS) is required for this change as permitted in the ASME Section IX.

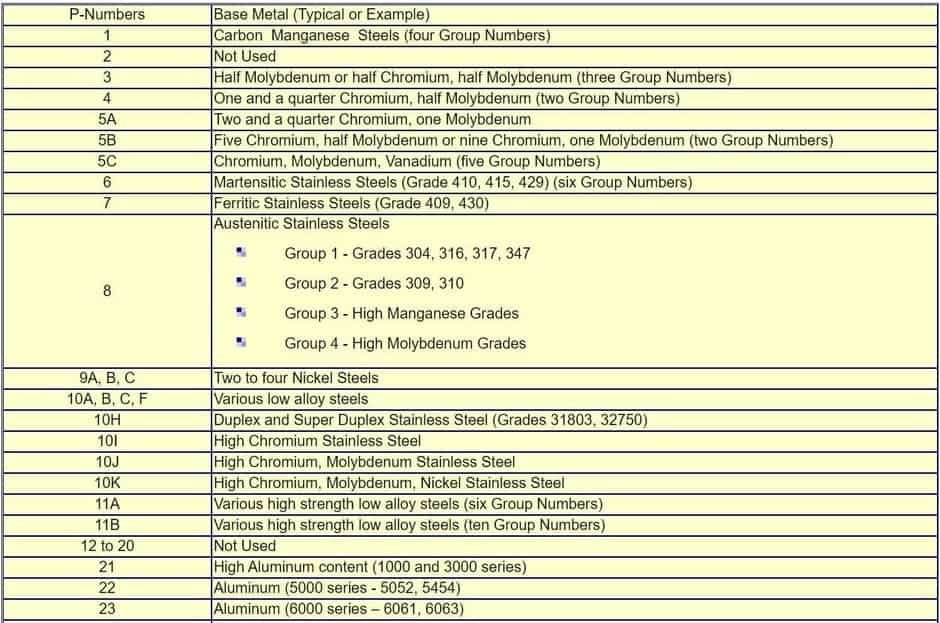

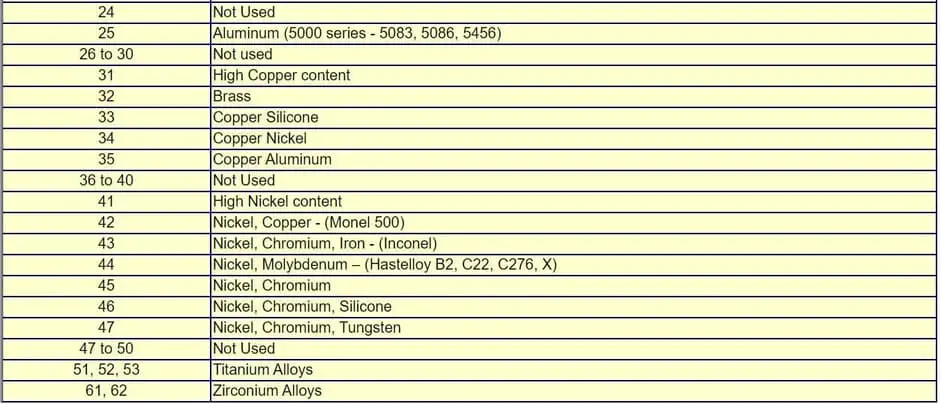

P-Number Table & P-Number List

The most important P-Number for different material groups are listed in the below table/ List for reference. The table provides an easy reference for various types of materials P-Number used for procedure and performance qualification.

Click here to download ASME P-Number Table.pdf

Why P-Number in Welding is required & what is P-Number importance?

The P-Numbers help to reduce the range of WPS qualification requirements. For example, a WPS qualified with SA516 material which falls under P1 material can be used to weld any other material falling within the same P-Number.

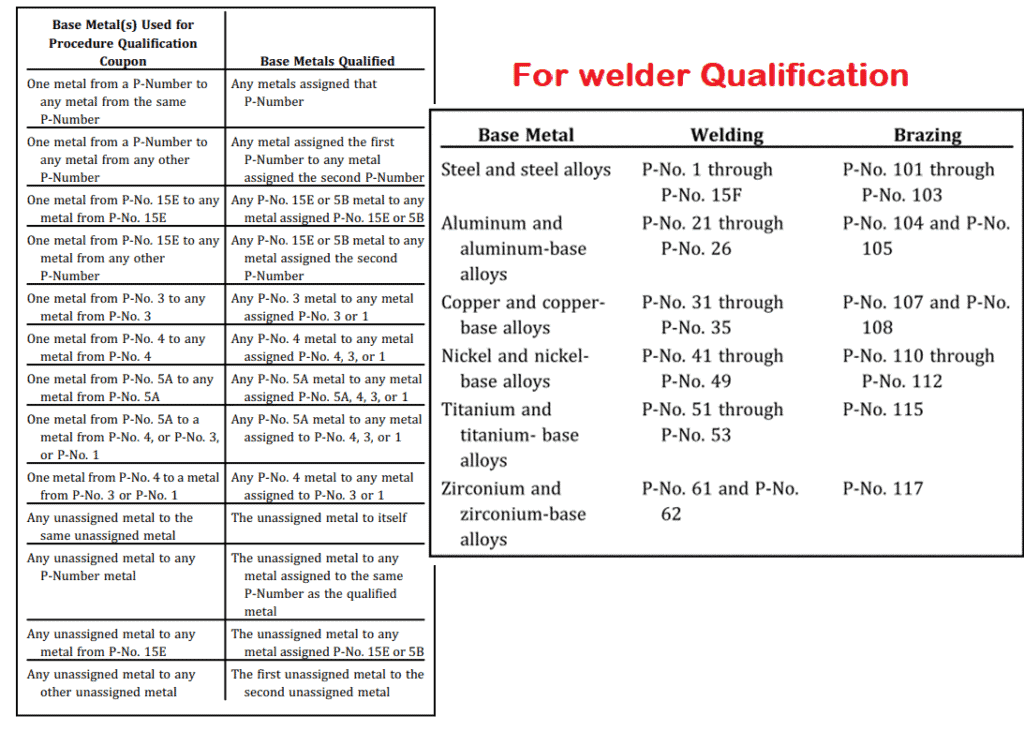

Below is a summary of material types based on P-Number according to ASME Section IX for welder qualification and procedure qualification.

Do all materials have a P-Number?

No, not all materials have a P-Number. The American Society of Mechanical Engineers (ASME) Section 9 outlines the materials that need a P-Number.

Materials that need a P-Number are those that are in contact with pressurized piping & pressure vessel systems. The ASME Section 9 outlines the specific requirements for each material and assigns each a P-Number.

P numbers are specified in ASME Section IX and as we know ASME only covers materials that are used for the construction of boilers, pressure vessels, piping, nuclear, and related ASME code constructions.

So, not all of the materials will have the P-Numbers.

What is S- Number in Welding?

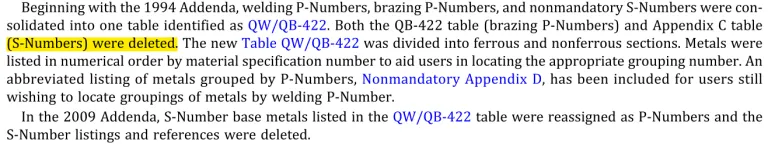

S-Number was similar to P-Number and used in the ASME in past but they were removed in 2009. So, S-Numbers are no more in practical use in welding engineering and are no more relevant.

In ASME Section 9, 2009 edition, S-Numbers were merged with P-Number. Refer to the below code explanation.

What are the P1 Materials?

The P1 designation is assigned by the American Society of Mechanical Engineers (ASME) to materials that meet certain criteria for chemical and mechanical properties. These materials are specified in ASME section IX, which is the standard for welding qualification.

P1 materials are simple carbon steel materials. If I say precisely they are C-Mn steel as the main alloying elements are carbon and manganese. Example of P1 materials are ASTM A105, ASTM A106, ASTM A36, ASTM A516.

ASME P1 Material List

An ASME P1 material list is a list of materials that are approved for use in construction and pressure vessel applications. The list is maintained by the American Society of Mechanical Engineers (ASME) and can be found in ASME Section IX- Table QW/QB-422 for Ferrous & Non-Ferrous Material P-Numbers.

Below is ASME P1 Material List for reference:

- A/SA–36

- A/SA–53

- A/SA–105

- A/SA–106

- A108

- A/SA–134

- A/SA–135

- A139

- A/SA–178

- A/SA–178-9

- A/SA–181

- A/SA–216

- A/SA–266

- A/SA–283

- A/SA–333

- A381

- A/SA–414

- A/SA–513

- A/SA–516

- A/SA–519

ASME P1 Group 1 Material List

An ASME P1 Group 1 material list is a list of materials that are approved for use in construction and pressure vessel applications. The list is maintained by the American Society of Mechanical Engineers (ASME) and can be found in ASME Section IX- Table QW/QB-422 for Ferrous & Non-Ferrous Material P-Numbers.

P-No. 8 Materials Group List

P-No. 8 Materials Group List is a list of austenitic stainless steel materials that are suitable for use in pressure vessels constructions.

Below is the P No. 8 Material group list:

- A/SA–182

- A/SA–213

- A/SA–240

- A/SA–249

- A/SA–312

- A/SA–351

- A/SA–358

- A/SA–376

- A/SA–409

- A/SA–451

- A/SA–479

You can find the complete list of P-Number 8 materials in ASME Section IX, QW-422 Table.

Duplex Stainless Steel P Number

P numbers are assigned to duplex stainless steels based on their chemical composition. The P number also corresponds to the maximum service temperature for the particular steel.

The most commonly used duplex stainless steel P-Number are:

- S32550 : P- Number 10H, Group No. 1

- S32750 : P- Number 10H, Group No. 1

- S32760 : P- Number 10H, Group No. 1

- S32615 : P- Number 8, Group No. 1

- S32906 : P- Number 10H, Group No. 1

- S32950 : P- Number 10H, Group No. 1