Difference between heat no, lot no & batch no in material certificate

Material certificates play an important role in manufacturing industries. They are used to provide information about the chemical and physical properties of a material used for production.

Within these documents, you will typically find references to heat no, lot no, and batch no. Although these terms may seem interchangeable at first glance, they each have distinct meanings.

Understanding what each term means on a material certificate can be challenging, especially when it comes to heat number (HN), lot number (LN), and batch number (BN).

Heat No vs. Lot no vs. Batch no

Heat No, Lot No, and Batch No are all used to identify the manufacturing process and traceability of materials in various industries. Here are the key differences between these terms:

- Heat No: Heat No refers to the identification number assigned to a specific batch of raw material used in the production process (each melt produced every time in a steel making furnace will represents one heat).

- Lot No: Lot No refers to a specific quantity of a product (specific lot) that is produced at one time and has a unique identification number. It is used in the manufacturing of products such as pharmaceuticals, food, and chemicals. Lot No helps to track the production process and ensures that products are manufactured according to the required specifications.

- Batch No: Batch No is similar to Lot No and refers to a specific quantity of a product that is produced at one time and has a unique identification number. It is used in the manufacturing of products such as cosmetics, consumer goods, and electronics. Batch No helps to track the production process and ensures that products are manufactured according to the required specifications.

Here’s a table summarizing the key differences:

| Term | Use | Example |

|---|---|---|

| Heat No | Identification of raw material | Used in the production of steel or other metals |

| Lot No | Identification of a specific lot | Used in the production of pharmaceuticals or food |

| Batch No | Identification of a specific batch | Used in the production of cosmetics or electronics |

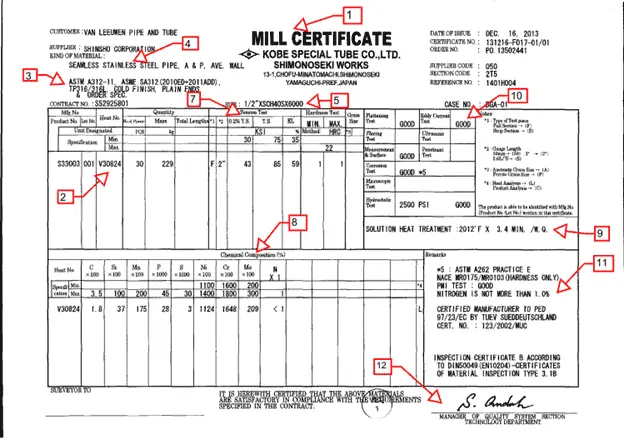

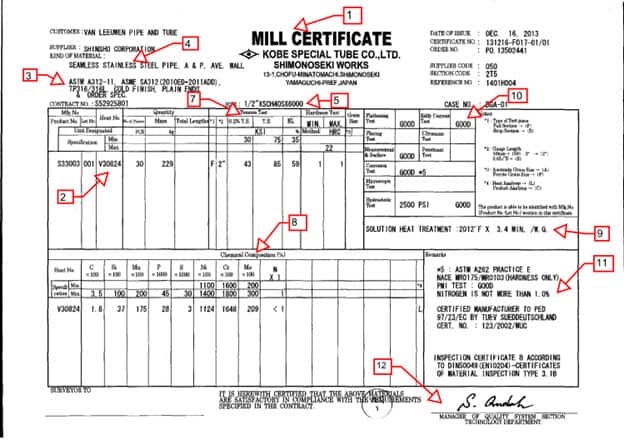

Meaning of Heat Number in a Material Certificate (MTC)

The heat number in a material certificate, also known as MTC, is an essential aspect of the documentation process for manufacturing companies.

Heat numbers are unique identifiers that signify the specific batch or heat of metal used to create a particular product. This information is important because it helps manufacturers track and trace their products.

Heat numbers refer to a unique code that identifies the specific steel mill where a particular batch of raw materials came from. This code is crucial in tracking the quality and composition of steel used in manufacturing products.

Heat numbers serve various purposes in the manufacturing industry. For instance, if a product fails quality control tests, manufacturers can quickly identify which batch or heat was used to produce it and implement corrective measures. Additionally, heat numbers enable companies to monitor their supply chain processes better by tracking raw materials’ origins and suppliers’ performance.

Meaning of Lot Number in a Material Certificate (MTC)

Lot numbers are assigned by manufacturers to identify batches during their production process. A lot may contain multiple items produced under similar conditions such as temperature, pressure or humidity levels.

The lot number is used to identify a specific batch or lot of raw materials produced by the manufacturer. It enables tracing back to its origin if there are any issues with quality or performance during production or use. Furthermore, it helps in maintaining consistency in product quality for future production runs.

Meaning of Batch Number in a Material Certificate (MTC)

While batch numbers are also used to identify batches manufactured at the same time or location, they often include additional information such as date codes or product identification numbers.

The batch number in a Material Certificate (MTC) is an important identifier that helps to ensure the traceability and quality control of materials. The batch number is typically assigned by the manufacturer, and it represents a specific production run or a lot of materials. This number allows for the identification and tracking of the materials used in a particular product, making it possible to quickly identify any issues or defects that may arise during production.

The batch number can also be used to provide information about the source and composition of the materials used in a product. For example, if a customer has concerns about allergens or environmental contaminants, they can use the batch number to determine where the raw materials came from and how they were processed.

Similarly, if there are questions about the quality of a particular product, the batch number can be used to investigate any potential issues with manufacturing processes or supply chain management.