What is Spray Arc Welding?

Spray arc welding is a high-deposition rate welding process that has gained popularity in various industrial applications due to its ability to produce high-quality welds quickly and efficiently.

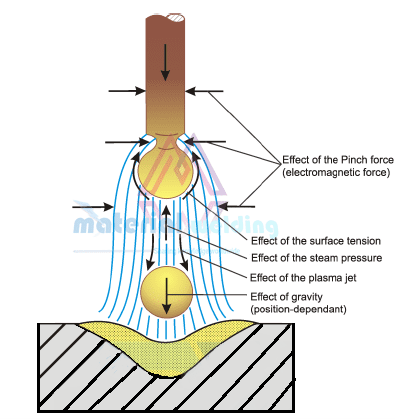

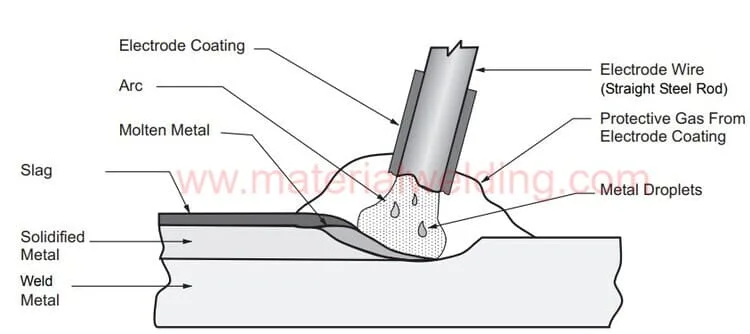

As its name suggests, the process involves creating a spray of small droplets of molten metal from a consumable electrode wire that is continuously fed into the weld pool. The droplets are propelled by the electric arc and deposit onto the workpiece, creating a strong and durable weld.

While the process requires specific conditions to be effective and can generate a significant amount of heat, proper setup and selection of the right welding parameters can lead to excellent results with a good weld bead appearance.

This article will delve deeper into the process of spray arc welding and provide insights into achieving the best results with this welding technique.

Related reading: Mode of metal Transfer in Welding

How does Spray Arc Welding work?

Spray transfer, also known as axial spray, is a welding metal transfer mode that occurs at higher current and voltage levels than globular transfer. To achieve spray transfer, an argon-rich shielding gas mixture with a minimum of 80% argon is used.

During spray transfer, the molten metal is transferred across the electric arc as a continuous stream of fine droplets, with a diameter typically smaller than the electrode wire.

The electric arc in spray transfer is stiff, and the droplets travel directly along the centerline of the electrode, making it easy to direct them into the weld pool without affecting the arc behavior.

Spray transfer is an efficient welding process that produces high-quality welds and is commonly used in industries such as automotive manufacturing, construction, and shipbuilding, where high production rates are necessary.

The controlled nature of spray transfer and its ability to produce welds with little to no spatter make it a popular choice for welders looking to achieve smooth, high-quality welds.

Advantages of Spray transfer welding

Spray transfer welding offers several advantages over other welding processes, including:

- High deposition rates: Spray transfer welding can achieve high welding speeds and deposition rates, making it suitable for high-volume production applications.

- Smooth, consistent welds: The fine droplets of molten metal produced by spray transfer result in smooth, consistent welds with minimal spatter and other welding defects.

- Better penetration: The high energy density of spray transfer welding can produce deeper weld penetration, resulting in stronger and more durable welds.

- Improved efficiency: The controlled nature of the spray transfer process reduces the need for post-weld cleanup and other secondary operations, leading to improved efficiency and lower overall costs.

- Versatility: Spray transfer welding can be used to weld a wide range of materials, including steel, stainless steel, and aluminum, making it a versatile welding process.

Disadvantages of Spray transfer welding

While spray transfer welding offers many advantages, it also has a few disadvantages to consider, including:

- Limited vertical and overhead welding: Spray transfer welding is best suited for flat or horizontal welding positions. It can be more challenging to use in vertical or overhead positions, which may require additional equipment and expertise.

- Higher equipment costs: Compared to other welding processes, spray transfer welding requires more advanced equipment, including a high amperage power source and a specialized spray transfer gun. This can result in higher initial equipment costs.

- More complex setup: The setup for spray transfer welding can be more complicated than other welding processes, requiring precise adjustments to the welding parameters to achieve the desired transfer mode.

- Greater sensitivity to environmental factors: Spray transfer welding is more sensitive to changes in the environment, such as wind or drafts, which can affect the stability of the arc and the transfer mode.

- Shielding gas requirements: Spray transfer welding requires a shielding gas composed of at least 80% argon, which can be more expensive than other shielding gases.

- Reduced weld quality with thicker materials: Spray transfer welding may not produce high-quality welds on thicker materials, as the increased heat input can cause distortion and other welding defects.

What is Transition Current in Spray Transfer Welding Mode?

The transition current refers to the current at which the mode of transfer changes from globular transfer to spray transfer in welding. In spray transfer, the welding wire is melted and atomized into fine droplets that are transferred across the electric arc and deposited onto the workpiece.

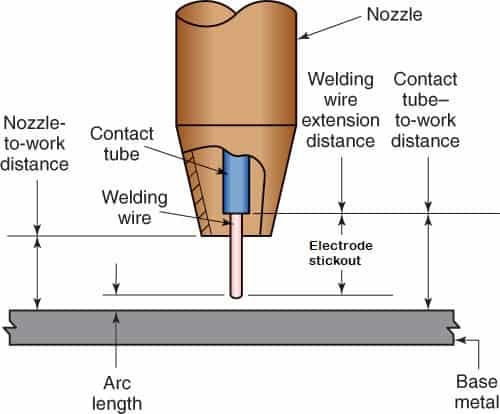

The transition current is affected by several factors, such as wire diameter, shielding gas composition, electrode composition, and electrical extension.

The optimal transition current can be determined by adjusting these factors to achieve a smooth and efficient transfer mode with minimal spatter. If the current is too low, the welding process may produce a globular transfer mode that can result in an uneven and inconsistent weld.

On the other hand, if the current is too high, the spray transfer mode can become unstable, leading to increased spatter and other welding defects.

Welders must carefully monitor the welding parameters and adjust them as needed to maintain the desired transfer mode and produce high-quality welds. Proper technique and setup are critical in achieving an optimal transition current for spray transfer welding mode.

What is Pulsed Spray Transfer Welding?

Pulse spray transfer is a variation of spray transfer welding. In pulse spray transfer, the welding power is cycled between low and high levels, with the high level being the point at which spray transfer occurs.

This cycle of power results in a lower average voltage and current compared to constant spray transfer. The lower average voltage and current can be beneficial in certain welding applications where minimizing heat input is important.

Pulse spray transfer can also produce a smoother and more controlled weld bead appearance.

Overall, pulse spray transfer is a useful technique for achieving specific welding outcomes and can be a valuable tool in a welder’s arsenal to control weld distortion, reduce HAZ size and overall welding heat input.

What gas do you use for spray transfer?

Spray transfer welding typically requires a shielding gas composed of at least 80% argon, with the remainder usually being a small amount of carbon dioxide or oxygen. The argon helps to stabilize the arc and prevent oxidation of the weld pool, while the carbon dioxide or oxygen improves arc penetration and can help produce a smoother weld.

Spray transfer welding is affected by the carbon dioxide content in the shielding gas mixture. Lowering the amount of carbon dioxide will decrease the transition current, making it easier to achieve spray transfer.

In fact, mixtures with 15% or less carbon dioxide are best for spray transfer. Additionally, a shielding gas mixture containing 85% to 92% argon is optimal for obtaining good penetration and a smooth appearance of the weld bead.

This gas composition range is suitable for welding thicker materials because the high current required for spray transfer results in higher arc energy and good penetration.

How to Set up your welder for Spray Transfer Welding?

Setting up a welder for spray transfer welding involves several steps:

- Choose the correct wire: Spray transfer welding typically requires a wire with a diameter of 0.035 inches or larger. The wire should be compatible with the base material being welded and the welding process being used.

- Select the appropriate shielding gas: As mentioned earlier, spray transfer welding typically requires a shielding gas mixture containing at least 80% argon, with the remainder usually being a small amount of carbon dioxide or oxygen.

- Set the voltage and wire feed speed: The voltage and wire feed speed should be set based on the wire diameter, material thickness, and other welding parameters. Generally, higher voltages of more than 22V, and 200 Amps are required for spray transfer welding.

- Test the setup: Before welding, it is important to test the setup by performing a test weld on a scrap piece of material. This will allow you to verify that the welding parameters are set correctly and that the shielding gas is providing adequate coverage.