What is Fusion Welding?

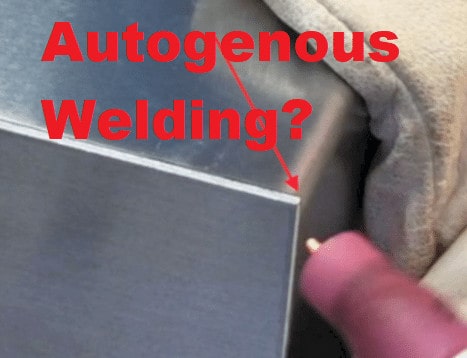

Fusion welding is a process of joining two or more materials by heating them to their melting point or above, followed by the solidification of the molten materials to form a strong, permanent bond.

The welding process relies on the melting of the materials to be joined, which are typically metals, to create a pool of molten material at the joint interface.

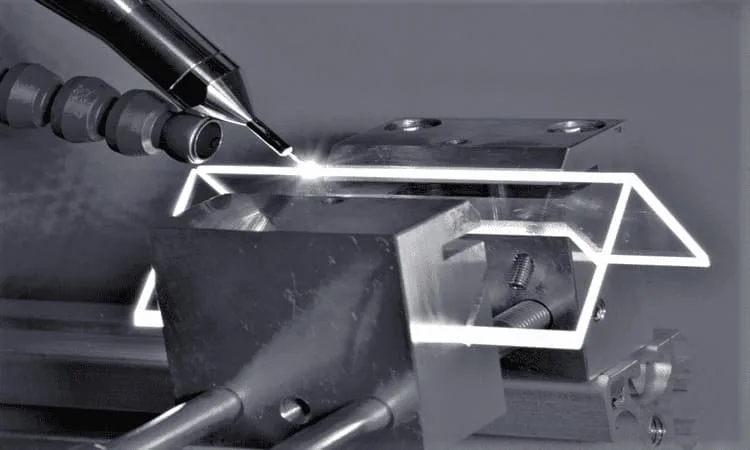

The heat input can be generated by various sources, such as an electric arc, a laser, or a gas flame.

The process involves the localized melting and solidification of the base material and/or filler material, with or without the application of pressure, to create the weld joint.

The resulting joint is often characterized by good mechanical properties, including high strength and toughness, due to the metallurgical bonding that occurs during the solidification process.

Types of Fusion Welding

Fusion welding is a category of welding processes that use heat to melt and fuse two or more materials together to form a joint. There are several types of fusion welding techniques that are commonly used in various industries. Here are some examples:

- Shielded Metal Arc Welding (SMAW)– Also known as stick welding, uses a coated electrode that melts and fuses the base metal.

- Gas Tungsten Arc Welding (GTAW) – Also known as Tungsten Inert Gas (TIG) welding, this process uses a non-consumable tungsten electrode to produce the arc and filler material is added manually.

- Gas Metal Arc Welding (GMAW) – Also known as Metal Inert Gas (MIG) welding, this process uses a consumable wire electrode and a shielding gas to protect the weld from atmospheric contamination.

- Plasma Arc Welding (PAW) – This process is similar to GTAW but uses a more concentrated plasma arc to achieve higher welding speeds and deeper weld penetration.

- Submerged Arc Welding (SAW) – This process uses a continuous, consumable wire electrode and a granular flux to shield the weld from the atmosphere, which allows for high welding speeds and deep penetration.

- Electron Beam Welding (EBW) – This process uses a highly concentrated beam of electrons to generate heat and melt the materials to be joined. EBW is typically used for precision welding applications.

- Laser Beam Welding (LBW) – This process uses a highly focused laser beam to generate heat and melt the materials to be joined. LBW is commonly used in the automotive and aerospace industries for high-speed, automated welding.

What is the basic principle of fusion welding?

The basic principle of fusion welding is to create a strong, permanent bond between two or more materials by melting them and allowing them to solidify into a single piece.

The welding process relies on the localized heating of the materials to be joined to a temperature above their melting point, which causes them to form a pool of molten material at the joint interface.

This pool of molten material is then allowed to solidify, forming a metallurgical bond between the materials.

During the solidification process, the atoms in the molten material arrange themselves into a crystal lattice structure, which results in the formation of a solid, continuous weld joint.

The heat input required to melt the materials and create the weld pool can be generated by various sources, such as an electric arc, a laser, or a gas flame.

What is the difference of fusion and non-fusion welding?

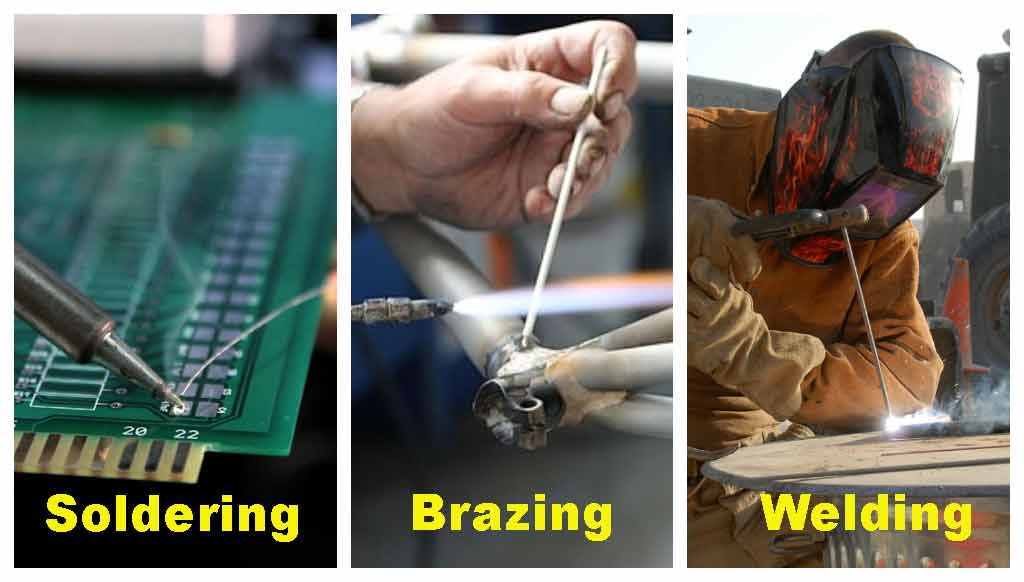

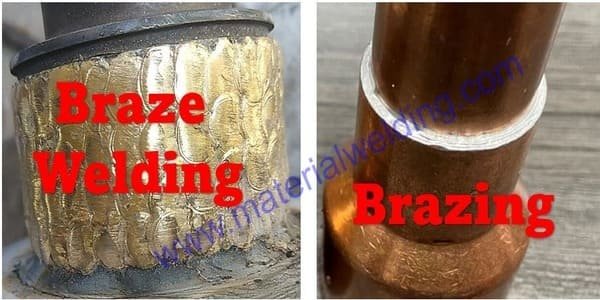

The main difference between fusion and non-fusion welding is the way in which the joint is formed between the materials being joined.

In fusion welding, the materials are melted and fused together to form a solid, continuous joint.

This process involves heating the materials to their melting point or above, typically using an external heat source such as an electric arc, a laser, or a gas flame. The molten materials are allowed to solidify, forming a strong, permanent bond between the materials.

On the other hand, non-fusion welding techniques do not involve melting the materials being joined. Instead, these techniques rely on mechanical or chemical bonding to create the joint.

For example, in resistance welding, pressure is applied to the materials to be joined while an electric current is passed through them, causing them to bond together. In adhesive bonding, a specialized adhesive is applied between the materials, creating a strong bond.

| Aspect | Fusion Welding | Non-Fusion Welding |

|---|---|---|

| Joint Formation | Materials are melted and fused together to form a solid, continuous joint | Joint is created through mechanical or chemical bonding, without melting the materials |

| Heat Input | Heat is applied to the materials to be joined, typically using an external heat source such as an electric arc, a laser, or a gas flame | Heat is not used to melt the materials |

| Properties of Joint | Creates a strong, permanent bond between the materials | Bond strength depends on the type of non-fusion welding used |

| Examples of Applications | Automotive, aerospace, and construction industries, where strong, permanent joints are required for structural components | Electrical and electronics industries, where non-fusion techniques such as soldering and adhesive bonding are used to join delicate or heat-sensitive components |

While both fusion and non-fusion welding techniques have their own advantages and disadvantages, fusion welding is typically preferred for applications where a strong, permanent bond is required between the materials.

Non-fusion welding techniques are often used when it is not feasible or desirable to melt the materials, or when a different set of properties, such as corrosion resistance, is required in the joint.

What are the advantages of fusion welding?

Fusion welding offers several advantages over other welding techniques:

- Strong, permanent bond

- Versatility

- Efficiency

- Precision

- Cost-effective

- Clean process

Disadvantages of fusion welding?

Here are the disadvantages of fusion welding, listed by name:

- High heat input

- Limited thickness range

- Specialized equipment

- Safety hazards

- Environmental impact

- Weld quality variation