Autogenous Welding definition

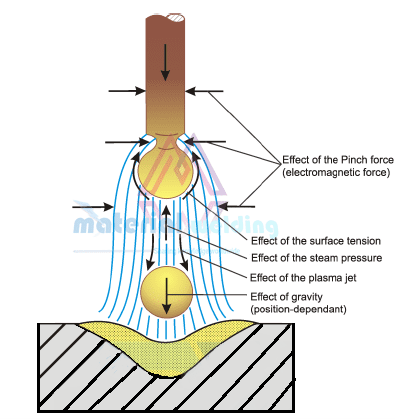

Autogenous welding is a technique of fusion welding process where welding is performed without the welding electrode or filler material. Note to mention that Autogenous welding is not similar to SMAW, GTAW, or MIG/ MAG etc.; but instead, it is one of the techniques of the existing fusion welding processes.

Solid-state joining processes such as friction welding, friction stir welding, explosive welding are also autogenous welding methods because they work without the application of any filler metals. Autogenous welding is very beneficial for welding thin sheet metal as this will produce very low heat input.

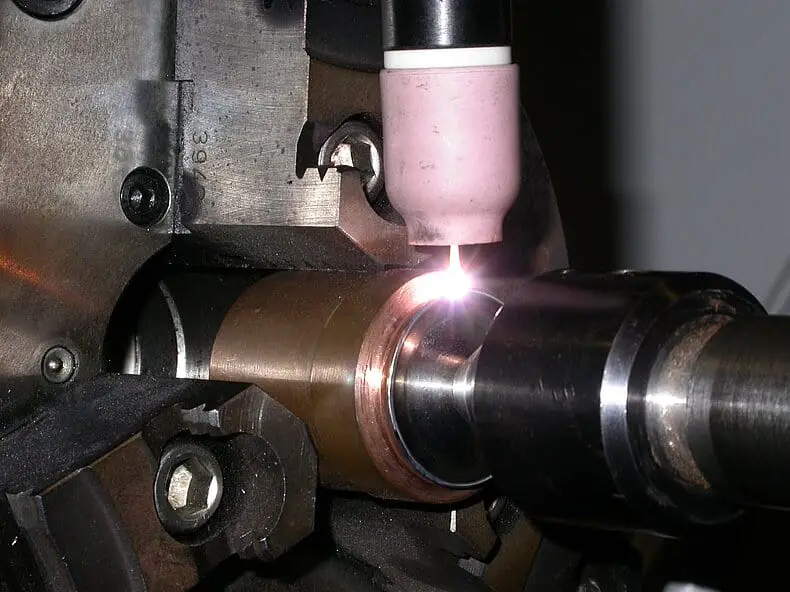

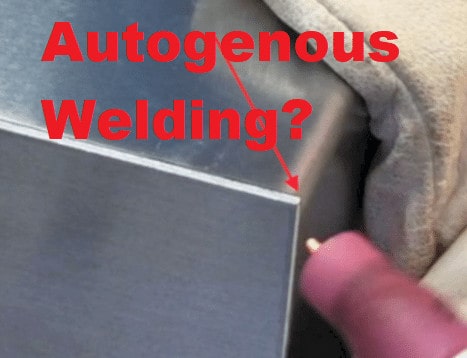

What is Autogenous TIG Welding Process?

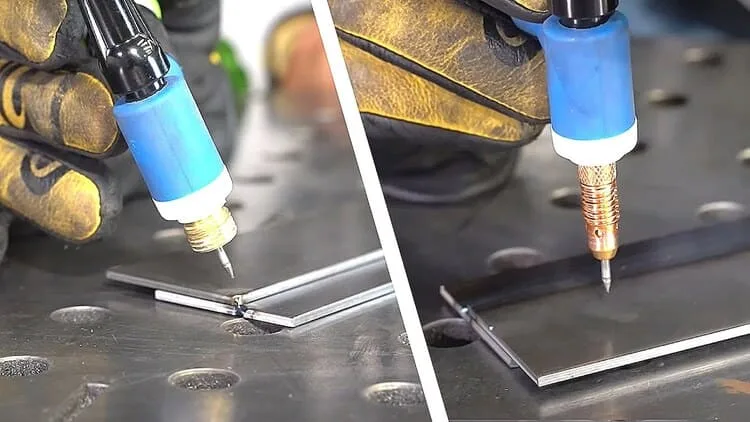

TIG welding when used without externally supplied filler wire is known as Autogenous TIG welding.

This welding method is good for welding thin sheet metals, welding temporary tacks during fitment stage.

One of the most important uses of Autogenous TIG is for TIG refusion of welds where the weld toes are fused with TIG welding without filler wire.

This ensures no lack of fusion or overlap presents at the weld toe thus increase the fatigue life of the welds.

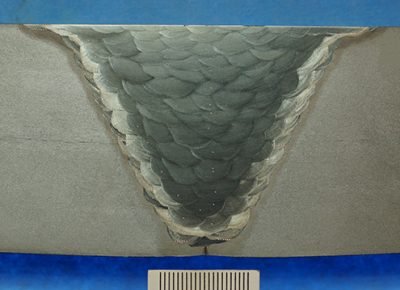

What is an autogenous weld?

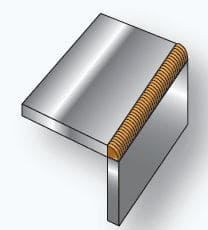

An autogenous weld is a type of weld in which the two pieces of metal being joined are fused together without the use of any filler material.

This is achieved by heating the metal to its melting point and bringing the pieces together under pressure to create a bond.

Autogenous welding is typically used when joining similar metals and can be done by various methods such as TIG welding, MIG welding, and plasma welding.

It is known for its high quality, but it’s also the most difficult method to perform.

Example of Autogenous Welding

Advance welding processes (AWP) for example electron beam welding, plasma welding, laser welding and mostly used as an autogenous technique to make weld joints.

Not all the welding processes can be used in an autogenous way as the welding electrode or filler wire is an essential part of the welding process. Such as SMAW welding is not possible without the welding electrode.

The same applies to MIG/ MAG welding, Flux Cored Arc Welding (FCAW), Submerged arc welding (SAW), etc. as they always use consumable filler material and thus cannot be performed in an autogenous way.

Advantages of Autogenous welding

Autogenous welding offers a number of benefits compared to the other two fusion welding methods. The main advantages of autogenouse welding are:

- Good visual welds. Autogenous welding processes create more even weld compare to weld with filler.

- Improved fatigue properties: TIG refusion is usually carried out using Autogenous TIG on weld toes to increase the fatigue resistance of the welds.

- Reduced post weld grinding job. Autogenous TIG require little grinding as not additional filler is added.

- Reduced material costs. AS no filler is required, cost of welding joint is low.

- Easy to weld thin materials. This technique suits best of thin materials due to low heat input and easy control of the weld puddle.

- Ease in automation. Using a special purpose machine (SPM) or other suitable means, autogenous welding can be easily automated.

Disadvantages of autogenous welding

The main Disadvantages of autogenous welding are:

- Not suitable for open root joints and other joint types excepts butt welds.

- Limited to thin materials joining usually up to 3 mm. Joining higher thickness will have risk of adequate penetration.

- Dissimilar welds due to dilution will produce change in the weld properties.

- Weld are weaker as they will have underfill issue because the weld puddle is produced by melting the adjacent base material.

- Welds are prone to crack during solidification in material which lacks ductility.

- Not suitable when joining more than two parts or joint with more than two thickness for example cruciform joint.

- Welding is only possible for square butt joints.

- Weld need to be fully cleaned to produce sound joints.

What is autogenous homogeneous and heterogeneous welding?

Autogenous welding is a type of welding in which the two pieces of metal being joined are fused together without the use of any filler material.

Homogeneous welding refers to the process of joining two pieces of metal of the same composition and thickness.

Heterogeneous welding refers to the process of joining two pieces of metal of different composition or thickness.

FAQS:

Is TIG (GTAW) welding Autogenous?

Yes & No Both. No, if a filler wire is added during welding, then TIG welding or GTAW is not a autogenous welding process.

Yes, it is possible to use TIG welding as Autogenous welding. You can use TIG (GTAW) without filler to join metals. If used so, it is known as Autogenous TIG Welding.

Is MIG welding Autogenous?

No, MIG Welding is not a autogenous Welding process. MIG need mandatory filler wire to produce a welding joint.

Hence, it is not possible to use MIG-MAG (GMAW) or FCAW or SAW, welding as an autogenous welding processes.

Which Welding Processes are Autogenous?

TIG Welding, Plasma Welding, Electron Beam Welding and Laser Welding processes can be used as Autogenous welding process.