What is FCAW-G and its meaning?

FCAW-G stands for Flux-cored arc welding-Gas Shielded & is the most used FCAW technique in the industries.

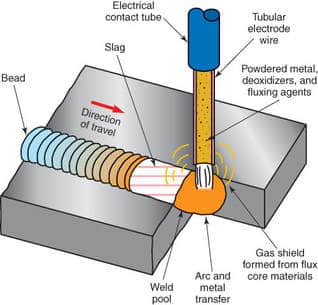

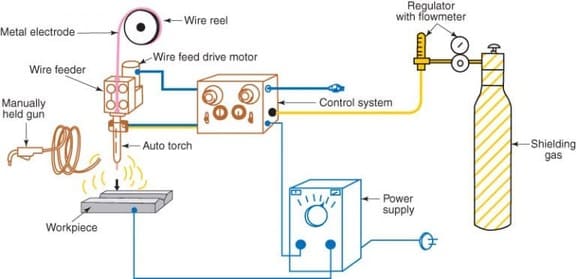

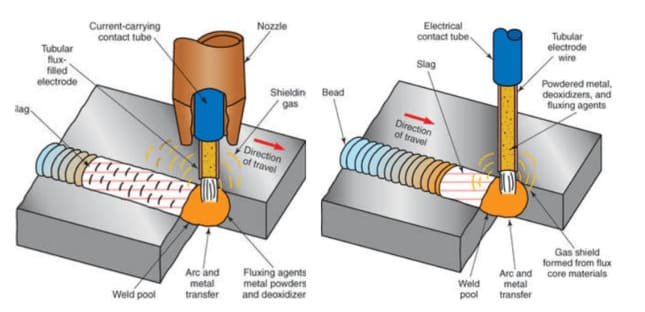

In FCAW-G, external shielding gas is used similar to MIG Welding. As the flux-cored wire also has flux coating to create shielding gases, they are not sufficient enough to provide full shielding and external shielding gas (Mainly CO2 as it’s cheaper) is supplied.

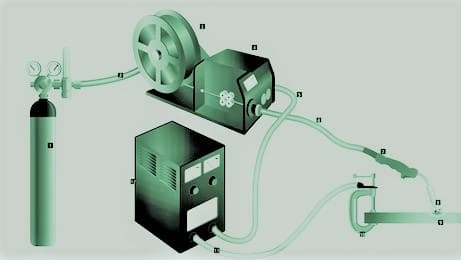

Argon + CO2 mixtures are also used as shielding gas. The arrangement of FCAW-G is shown in the below figure. Usually, FCAW-G indicates or refers to CO2 as a shielding gas to be used for welding.

The cost of Flux-cored wire electrodes is higher compared to solid welding filler wire and hence their uses are limited for higher productivity jobs or when need specific welding requirements.

Click here to learn about Flux Cored Arc Welding (FCAW)

The actual 3D sketch of the FCAW-G equipment setup is shown below.

What is FCAW-S and its meaning?

FCAW-S is also known as flux-cored arc welding- Self Shielded. The flux-cored self-shielded wires are used in the FCAW-S technique.

The wire is similar to a Stick welding rod but internally filled with flux and in the form of a roll.

The coating elements in the wire have enough flux to create sufficient gas shielding without the need for any external shielding gas like required in FCAW-G.

The flux in the coating burns and produces the shielding gases and the slag which solidify.

Click here to learn about Shielding gases for MIG-MAG, TIG, and FCAW welding and shielding gases purity

What are at least 2 differences between FCAW-S and FCAW-G

The main two differences between FCAW-S and FCAW-G are:

- FCAW-G stands for flux-cored arc welding-gas shielded while FCAW-S means flux-cored arc welding-self shielded.

- FCAW-S produces more welding fumes compared to FCAW-G.

- FCAW-G is less portable process due to external shielding gas bottle, while FCAW-S is highly portable welding process.

FCAW-S vs. FCAW-G

Both FCAW-S and FCAW-G types of flux-cored arc welding. The only difference between both is the type of Cored wire.

FCAW-S produces shielding gases required for the weld in sufficient quantity and FCAW-G requires additional externally supplied shielding gases to protect the weld pool.

Both FCAW-S & FCAW-G can be welded using the same welding machine and no separate welding machine is required.

FCAW-G vs. MIG welding

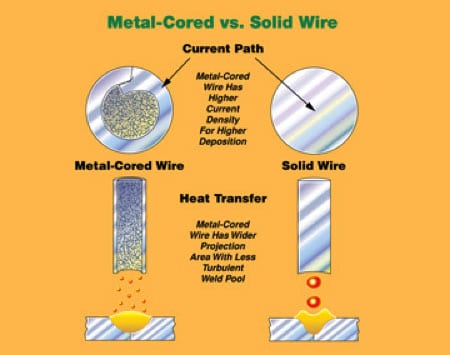

The main difference between FCAW-G to MIG or GMAW welding is based on the type of welding wire.

While the MIG welding (GMAW) uses a solid wire spool, the FCAW-G are cored wires with internally filled flux.

Both the process can be used with the same welding machine without any modification.

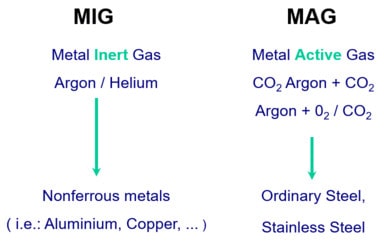

Also, MIG stands for Metal inert gas, so the shielding gas is used in pure argon, while in FCAW-G, we usually use CO2 or a mixture of Argon + CO2 gases as shielding.

FCAW Meaning

FCAW meaning is Flux Cored Arc Welding. It is a type of welding that uses a wire electrode that is fed through a welding gun and into the weld pool. The wire electrode is made of a core of flux and metal that is melted as it goes through the arc.

FCAW was developed in the 1950s and has become increasingly popular because it is portable, does not require a shielding gas, and can be used in all positions. It is often used for welding thicker materials, such as steel plate, and can be used to weld both ferrous and non-ferrous metals.

There are two types of FCAW: self-shielded and gas shielded s explained earlier in this post. In self-shielded FCAW, the wire electrode contains ingredients that release gasses that shield the weld pool from oxidation and contamination.

Types of flux coating in FCAW wire

The flux filling in FCAW wire consists of several raw materials and among other things including arc stabilizers for achieving high process stability, alloying elements for the use of metallurgy, and partly micro-alloyed elements to improve the quality of the metal weld through nucleation.

These micro-alloyed elements also provide a fine grain structure in the weld deposit.

The flux coating also includes gas-forming agents and deoxidizers.

The main coating element defines the type of FCAW wire for example a rutile coating or acidic type.

In rutile coating, Titanium Oxide (TiO2) is found as the main coating element along with calcium carbonated which produces shielding gas such as Co2 and CO after burning during welding.

Alloying elements are added using their ferro products such as ferrosilicon, Ferromanganese, Ferro boron, etc. which provide weld deposit with Si, Mn, and Bo respectively for example.

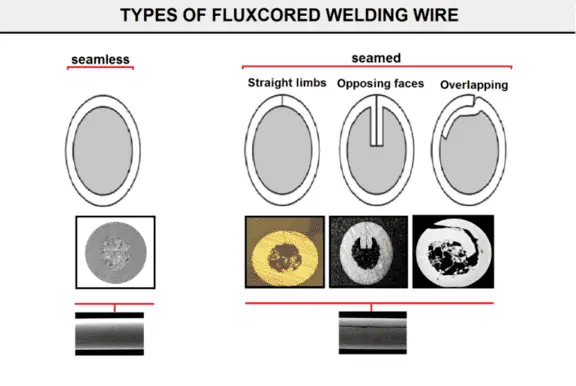

Cross-section of flux-cored wires

According to the construction of the wire cross-sections, seamless and shape-closed flux-cored wire filler wire are available in the market.

Various types of the cross-section are used in the manufacturing of the flux-cored wires along with the latest seamless wire technology adapted by many new manufacturers.

The various cross-sections of FCAW wires are shown in the below diagram.

How Flux-cored wire is made?

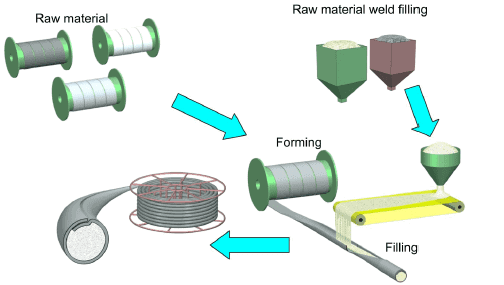

The flux-cored wire is manufactured by the welding companies and as a pre-material, for enclosed types, a narrow strip with a slightly more than 10 mm width and less than 1 mm thick is used and brought fist into a U-shape by bending rollers.

This is followed by filling the dry flux in the hollow wire. Subsequently, the cross-section is closed to form the wire and is usually reduced and compressed by rolling.

How seamless flux-cored wire is manufactured?

Seamless flux-cored wires are made from strips of approx. 2 inches (50 mm) width and around 2 millimeters thick.

This strip is converted to a tube welding it longitudinally using a continuous high-frequency welding line to make the cylindrical shape for flux filling.

This is followed by the recrystallization annealing process of the welded tube and then the tube is drawn to the filling diameter of the required size.

The filling flux, in this case, agglomerated, is inserted into the pipe by vibration and pre-compressed to ensure the right filling without any vacancy that can hold moisture.

Next, the semi-finished wire is drawn to the size of the annealing diameter. Here, heat treatment is applied to minimize the hydrogen in the flux to much lesser than 5ml/100 gram & provide annealing to the wire.

After this, the wire is processed by several steps to reduce it to the final required diameter size, clean it, and apply any copper coating if required. Copper coating on the flux core wire improves the current transmission from the welding gun tip to the wire.

What are two categories of FCAW wire types?

The main two categories of FCAW wire types are:

- Flux cored arc welding Self -shielded wires

- Flux cored arc welding Gas -shielded wires

Self-shielded welding wires does not require external shielding gas while gas-shieled welding wires need external welding gas supply to protect the weld pool.

What provides shielding during FCAW-S?

The shielding in FCAW-S is provided by the gases produced by burning of flux in cored wire. The covering made from Fluorspar, Calcium oxides and other organic compounds burns and produce CO2 that gives shielding during FCAW-S.

Advantages of Flux Cored Wire Welding

Flux-cored wire offers numerous advantages compared to solid wire. They are:

- Good wetting, notch-free transitions, smooth surface

- High crack resistance

- Low spatter droplet transfer

- High process stability

- X-ray-safe welds

- Applicability of micro-alloy elements

- Good suitability for out-of-position welding

- Economic manufacturing

Read more: