Difference between MIG and MAG welding?

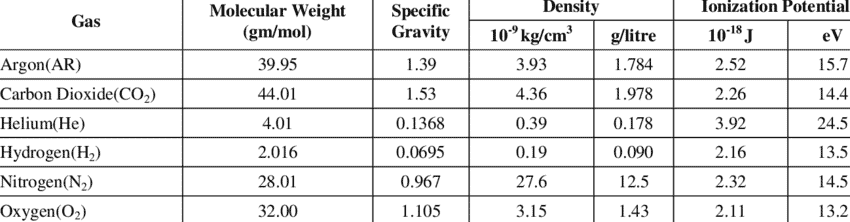

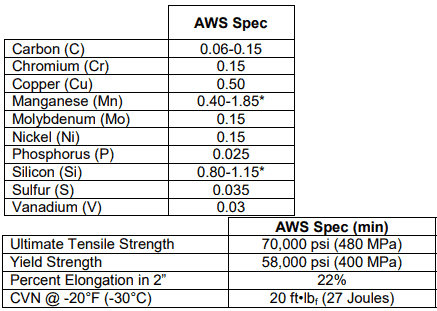

When we compare MIG & MAG welding both are gas shielded metal arc welding. But the difference between MIG and MAG welding processes depends upon the type of shielding gases used during the welding operation.

Click here to learn various types of shielding gases used in welding & their roles in Shielding.

Referring above figure, here MIG stands for metal inert gas using only inert or inactive gases for example argon and helium for shielding the weld. MIG welding is mainly used for non-ferrous metals like copper, aluminum, copper alloys, and titanium, etc.

Related Reading: Mig Welders vs Stick Welders: What’s the Difference?

Click here to learn about Shielding Gas used for Stainless Steel & Duplex Stainless Steel Welding.

MAG refers to Metal active gas. in MAG welding, active gas mixtures such as Carbon-dioxide, a mixture of Ar +CO2, Ar+O2, or Ar+H, or trimix of these three are used. Both the MIG and MAG welding are types of gas metal arc welding (GMAW) as explained earlier.

What is better MIG or MAG welding?

Many people get the two confused, but there are key differences between MIG and MAG welding. MIG (metal inert gas) welding is better for non-ferrous metals like aluminum, brass, and copper. MAG (metal active gas) welding is better for ferrous metals like steel and iron.

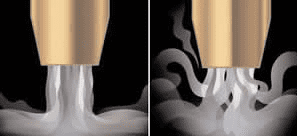

MIG welding produces a quality weld with less spatter than MAG welding. This is because the weld puddle is protected by an inert gas shield while it’s being deposited, which inhibits the formation of oxides that can create a weak weld.

MAG welding deposits more heat into the workpiece, which can be beneficial for thicker materials or when you need to create a deep penetration weld. MIG Welding uses inert gases such as Argon or Helium while MAG welding is carried out using with CO2 or mixture of Argon + CO2 welding gases.

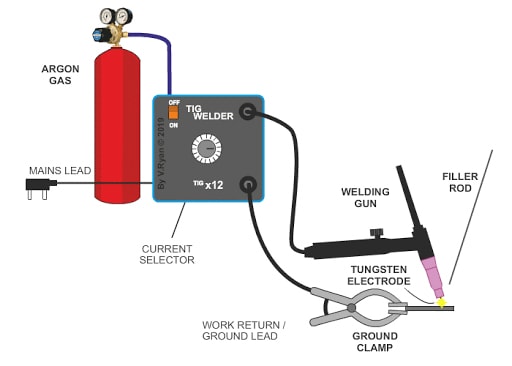

MIG vs MAG vs. TIG Welding

There are three main types of Fusion Welding Processes: MIG, MAG, and TIG. MIG welding uses a continuous wire feed and is good for non-ferrous metals & reactive metals (E.g, Copper, Brass, Nickel, Stainless Steel).

MAG welding also uses a solid wire that can be used on both thin and thick metals. MIG Uses inert welding gases while MAG uses Active gases or mix of active & Inert gases. TIG welding is the most versatile type of welding, but it also requires the most practice to be proficient.

TIG is generally manual welding process while MIG & MAG are semi-automatic welding processes. Hence, TIG is comparative slower and less weld deposition compared to MIG-MAG.

Difference between MIG-MAG and TIG welding

MIG welding, MAG welding, and TIG welding are all different types of welding processes. Following are the differences between these processes:

- TIG & MIG uses Inert gases while MAG uses active gases.

- MIG & MAG uses solid wire spool for welding while TIG uses solid straight length (1 m) of wires.

- MIG-MAG has high weld deposit while TIG is a slow weld deposition process.

- TIG is a manual welding process, while MIG-MAG is semi-automatic welding process.

- TIG gives very clean welds compared to MIG-MAG.

- TIG is more portables compared to MIG-MAG.

Gas Metal arc Welding (GMAW)

Gas metal arc welding or GMAW is the broad classification for various gas shielded metal arc welding processes such as metal inert gas or MIG, Metal active gas or MAG, Electric gas welding or EGW, and Flux-cored arc welding or FCAW.

All above welding processes requires external shielding gas to protect the weld pool and hence they are called Gas Metal Arc Welding (GMAW).

What is Metal Inert Gas (MIG) Welding?

MIG welding is a process that uses inert shielding gas and a continuous solid wire feed to join metal parts. The wire feed ensures a consistent weld bead, while the shielding gas protects the weld from contamination.

MIG welding can be used on a wide variety of materials, including steel, aluminum, and stainless steel. It is a popular choice for home handymen and professionals alike because it is easy to learn and produces high-quality welds.

What is Metal Active Gas (MAG) Welding?

Metal active gas (MAG) welding is a process that uses an active welding gas to produce a weld. A continuous solid wire feed is used to produce the weld, and a CV power source is typically employed.

The result is a clean and strong weld that can be used in a variety of applications. MAG welding uses CO2 or mixture of Argon + CO2 welding gases for weld pool protection. MAG welding can be used on a variety of metals, including steel, low alloy, and other ferrous metals.

The process can be used for both semi-automatic and automatic welding. MAG welding is often used in manufacturing and construction applications.

Welding process designation according to ISO 4063

MIG-MAG welding is also known as GMAW but the right word is MIG and MAG Welding. As per DIN EN ISO 4063, MIG & MAG welding is classified as given in the below table.

| Designation | Welding Process Name |

| 131 | MIG welding using solid wire electrode & inert gas |

| 132 | MIG welding using flux-cored electrode |

| 133 | MIG welding with metal-cored electrode & inert gas |

| 134 | MAG welding using solid wire electrode & active gas |

| 135 | MAG welding using flux-cored electrode & active gas |

| 138 | MAG Welding using active gas and metal-cored electrode |

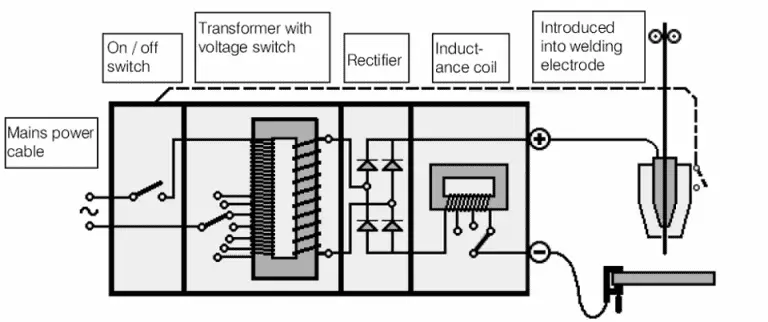

MIG welding uses inert or inactive gases for example argon and helium for shielding the weld while MAG welding uses active gases such as CO2. MIG welding is mainly used for non-ferrous metals like copper, aluminum, copper alloys, and titanium, etc. The below figure shows the diagram of a GMAW equipment setup.