6063 aluminum is a top choice for welding due to its good weldability. This means that it can easily be welded to other grades of aluminum without much difficulty subjected to using right filler wire, welding process and techniques.

This article covers complete welding guidelines for 6063 Aluminum Welding.

Can 6063 Aluminum be welded?

Yes, 6063 aluminum can be welded using TIG (tungsten inert gas) or MIG (metal inert gas) welding. It can also be joined by brazing or friction stir welding.

6063 aluminum is a popular alloy that is often used for applications such as window frames, door frames, roofs, and sign frames. It is also commonly used in the construction of boats and aircraft.

TIG welding is a popular option because it produces high-quality welds.

MIG welding can also be used, but it is not as common because it can cause the formation of oxides on the surface of the metal. Brazing and friction stir welding are two other options that can be used to join 6063 aluminums.

6063 Aluminum Chemical Composition

6063 aluminum is an alloy that is primarily composed of aluminum, magnesium and silicon. It is widely used for applications that require good formability and weldability.

The chemical composition of 6063 aluminum includes: 0.2-0.6% Si, 0.35% Cu, 0.1% Mg, and 97.0-99.0% Al. The remainder consists of Fe and trace impurities.

Complete chemical composition of 6063 aluminum are given in the below table as per ASTM B210 or BS 573-3.

| Element | Weight % |

|---|---|

| Silicon (Si) | 0.20- 0.60 |

| Iron (Fe) | 0.35 max. |

| Copper (Cu) | 0.10 max. |

| Manganese (Mn) | 0.10 max. |

| Magnesium (Mg) | 0.45- 0.9 |

| Chromium (Cr) | 0.10 max. |

| Zinc (Zn) | 0.10 max. |

| Titanium (Ti) | 00.10 max. |

| Aluminum (Al) | Remainder |

| Others | 0.15 max. |

6063 Aluminum Mechanical Properties

6063 aluminum is a magnesium-silicon alloyed aluminum that is primarily used in extrusions. It has good formability and weldability, as well as good corrosion resistance.

The mechanical properties of 6063 aluminum as per EN 755-2 are:

- Tensile Strength: 195 MPa minimum

- Yield Strength (Proof stress): 160 MPa minimum,

- Elongation %: 10 % minimum

6063 Aluminum Weldability

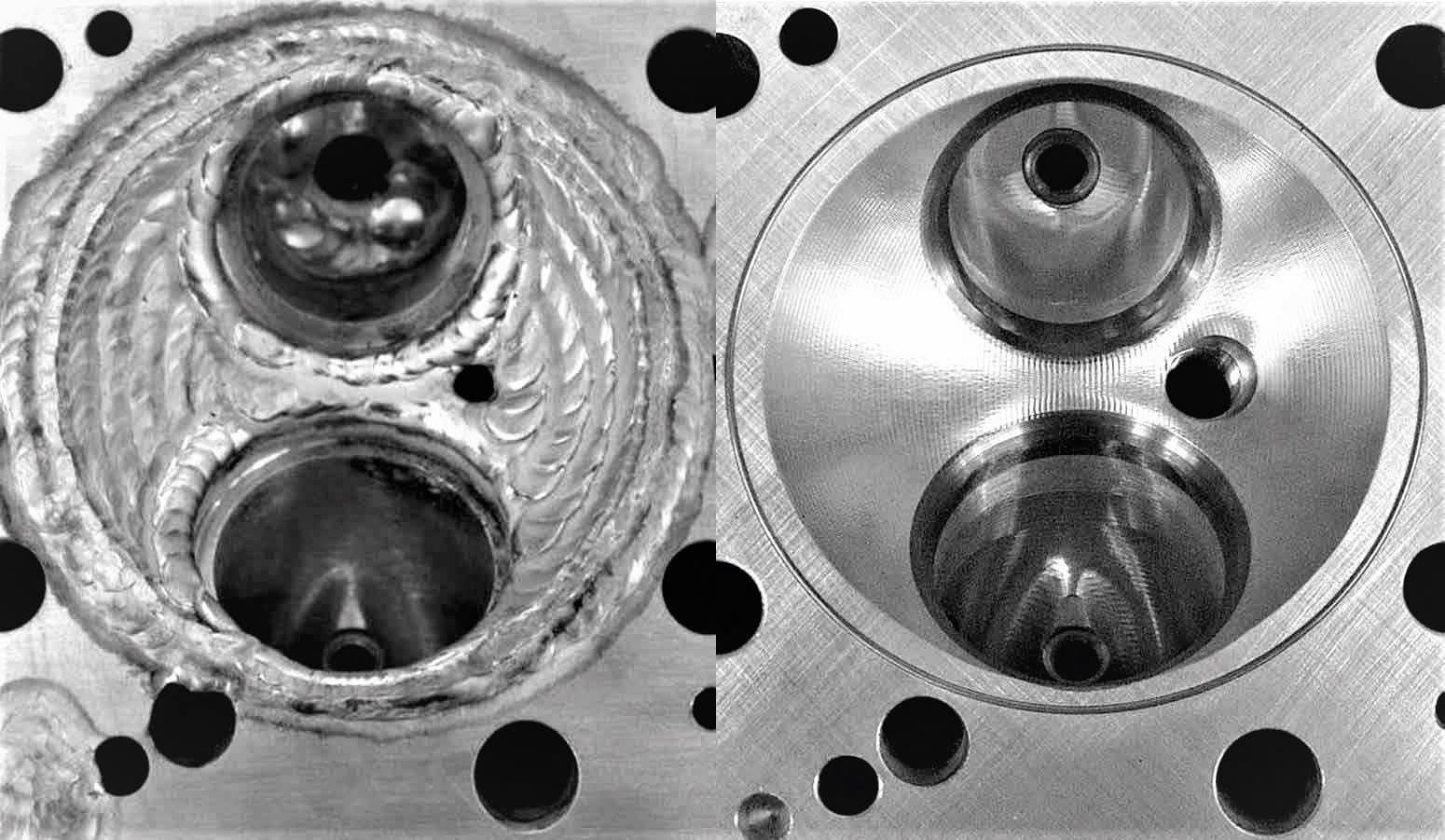

6063 aluminum has good weldability, but it is important to use the right filler rod and welding process for best results.

The most common filler rod for 6063 aluminum is ER4043. This filler rod has good corrosion resistance and can be used for both Tig and Mig welding processes.

For Tig welding, it is important to use a low amperage setting to prevent the formation of voids in the weld bead.

For Mig welding, a higher amperage setting can be used to create a wider and more robust weld bead. For best results, use a short arc welding process with a low heat input.

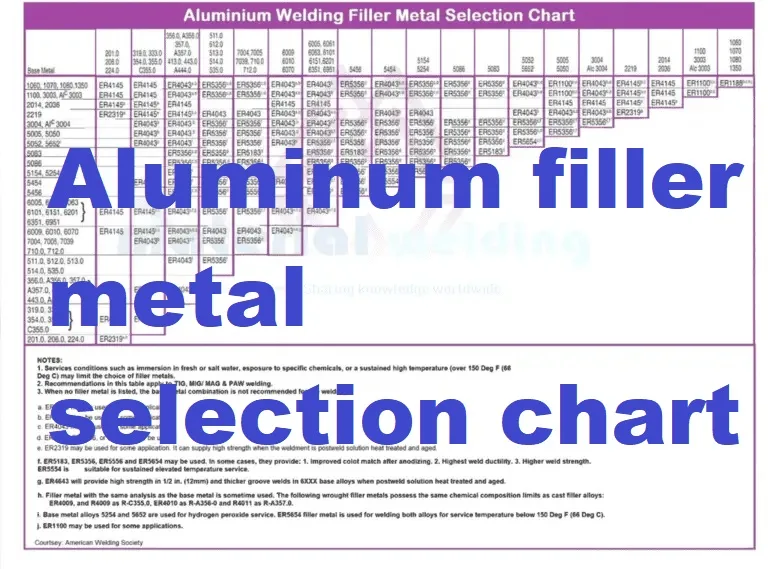

6063 Aluminum Welding Filler Rod

6063 Aluminum Welding Rod is ER4043 as per AWS A5.10 specification. ER4043 rod is a versatile, all-purpose aluminum welding rod. It is most commonly used to weld aluminum alloys that are heat-treatable and have good corrosion resistance properties.

This welding rod can also be used to weld non-heat-treatable alloys, such as cast aluminum alloys. This welding rod has good welder appeal because it produces minimal spatter in MIG welding and has a low melting temperature.

The AWS A5.10 specification covers aluminum welding wires and rods for gas-metal-arc and gas-tungsten-arc welding of aluminum alloys. According to this specification, the ER4043 aluminum welding rod meets the requirements for use with 6063 aluminum alloy.

TIG welding 6063 aluminum filler rod

6063 aluminum is a common type of aluminum alloy, and it can be welded using TIG welding. There are a few things to keep in mind when TIG welding 6063 aluminum, such as using the correct filler metal i.e., ER4043 and ensuring that the weld area is clean.

TIG welding 6063 aluminum grades shall be welded using ER4043 filler rod and pure argon gas shielding. You can use Argon+Helium mixture for welding thick aluminum.

There’s no preheat required during welding. Although for thicker aluminum material, preheat can be applied to maintain temperature gradient.

ER4043 filler rod is a great choice for TIG welding 6063 aluminum because it has good corrosion resistance and can be used on both thin and thick materials. Pure argon gas shielding protects the weld from oxygen contamination, which can cause porosity and make the weld weaker.

Check out my article on Welding Gases to know about different welding shielding gases and their selection.

6063 aluminum is widely used in the construction industry for things like window frames and door frames. It’s also used in the automotive industry for parts like radiators and fuel tanks.

AC polarity is easy to use and provides a stable arc that’s less likely to wander. It also helps prevent Tig welds from being too hot, which can cause distortion.

Welding 6063 Aluminum to 6061

6063 aluminum is known for its good formability and weldability, making it a popular choice for projects that require intricate shapes or detailed work.

6061 aluminum, on the other hand, is known for its strength and durability. It’s often used in structural applications where high strength is necessary.

In order to weld 6063 to 6061 aluminum together, ER4043 tig filler rod should be used. When welding with AC polarity, the heat will be evenly distributed and will help to avoid any warping or distortion of the metals.

Welding 6063 Aluminum to 5052

6063 aluminum is a widely used alloy for extrusion purposes. It has good formability and corrosion resistance, but is not as strong as other alloys such as 5052.

When welding 6063 to itself or another similar alloy, ER5356 filler rod should be used. This filler rod has good corrosion resistance and is strong enough to hold up against the forces exerted by 6063.

ER5356 is a common type of aluminum welding wire that is used to weld aluminum alloys such as 5052 and 6063. It has a good combination of strength and ductility, making it ideal for welding thin materials like aluminum sheet metal.

When welding aluminum, it’s important to use a lower voltage and amperage than you would when welding steel. This will prevent the aluminum from overheating and burning through.

Welding 6063 Aluminum to 3003

When welding 6063 aluminum to 3003, use a 4043 filler metal. This will help to create a strong weld that won’t break easily.

The two metals have similar weldability characteristics and can be easily joined together with the right welding rod and heat setting. Just be sure to use an argon gas shield and take your time when welding to avoid any issues.