ER5356 aluminum welding wire is a versatile Aluminum-magnesium base solid filler wire rod used for aluminum TIG and MIG Welding.

The main alloying element is magnesium around 4.5- 5.5%. The ISO 18273 equivalent of ER5356 is AlMg5Cr(A).

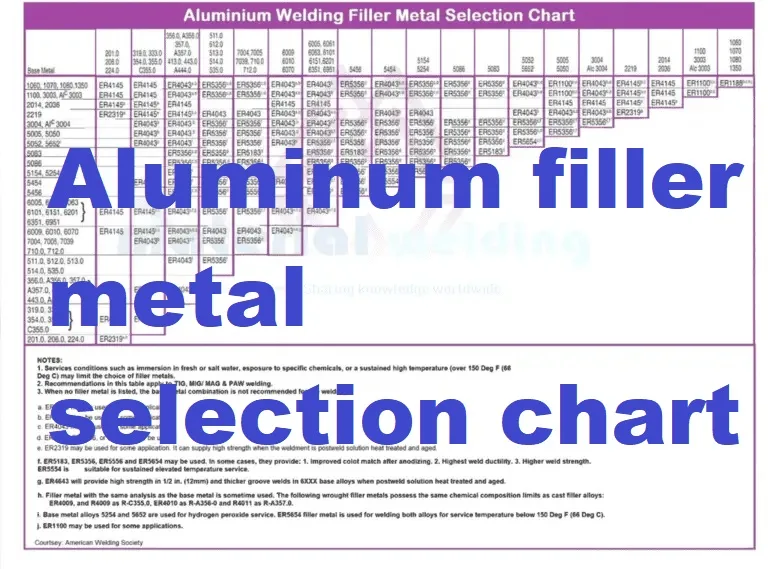

ER5356 welding wire is used for the welding Aluminum grades 1XXX series (1060, 1070, 1080, 1100), 5XXX series (5110, 5120, 5130, 5140, 5350), 6XXX series (6005, 6061, 6063, 6101, 6151, 6201) and 7XXX series (7004, 7005, 7039 and 7100).

ER5356 should not be used for high temperature applications. ER5356 melting point is 1060-1175°F (571-635°C).

ER5356 Welding wire Specification

ER5356 Welding wire Specification is AWS A5.10. ER5356 is this wire classification. The equivalent ISO Specification for ISO 18273.

ER5356 F-Number as per ASME Section IX is F-Number 22. The UNS Number for ER5356 is UNS A95356.

ER4043: TIG MIG Filler wire rod: Properties, uses & specification.

ER5356 Chemical Composition

ER5356 is an aluminum alloy that is commonly used in welding applications. The chemical composition of ER5356 welding wire required as per AWS A5.10 are:

| Element | Weight % |

|---|---|

| Silicon (Si) | 0.25 max. |

| Iron (Fe) | 0.40 max. |

| Copper (Cu) | 0.10 max. |

| Manganese (Mn) | 0.05- 0.20 |

| Magnesium (Mg) | 4.5- 5.5 |

| Chromium (Cr) | 0.05- 0.20 |

| Zinc (Zn) | 0.10 max. |

| Titanium (Ti) | 0.06- 0.20 |

| Aluminum (Al) | Remainder |

| Barium (Be) | 0.0003 |

| Others | 0.15 max. |

ER5356 is an aluminum alloy that is commonly used in welding applications due to its high corrosion resistance and weldability properties.

Check out my most liked article on Aluminum Welding Rods-How to Choose the Right One

ER5356 Mechanical Properties

ER5356 is an aluminum-magnesium TIG-MIG welding wire that is commonly used welding many different aluminum alloys. Mechanical properties of ER5356 are not specified in AWS A5.10 as only chemical test is required for this wire.

The reason for not specifying the mechanical properties for ER4043 is because of changes in strength due to different welding processes and heat input.

ER5356 typical Tensile strength is 29-45 Ksi (200 to 310 MPa) and Yield strength is 12-30 Ksi (83 to 207 MPa).

Aluminum is a soft metal and even its alloys are soft. ER5356 grade aluminum weld deposit hardness is generally in the range of 110- 130 HV.

ER5356 TIG Filler Rod

ER5356 TIG filler rod is an Al-Mg base aluminum alloy having good corrosion resistance and strength.

The wire is manufacturer according to the AWS A 5.10 specification and available in different diameters.

ER5356 MIG wire

ER5356 is a MIG wire used for welding aluminum. This wire is classified as an ER5356 because it contains 5% magnesium. The addition of magnesium to the aluminum helps improve the weldability of the metal. This wire can be used to weld a variety of aluminum alloys, including those with high silicon content.

ER5356 has a low melting point and strong weld penetration. This makes it ideal for welding thick materials or materials that are difficult to weld. The low melting point also allows the wire to be used in low-amp applications.

This wire produces little spatter and has good arc stability. These properties make it easy to use and produce clean welds that have a smooth finish.

ER5356 Welding Polarity

When welding with ER5356 wire, it is important to use the correct polarity in order to get the best results.

TIG welding is carried out using AC Polarity while MIG welding is generally carried out using AC Polarity or Pulse welding.

Welding with AC gives cathodic cleaning action that helps to eliminate welding porosity and gives good penetration.

To Learn about Welding Polarity in depth, Check out my article on Welding Polarity-Science behind it…

Welding with DCEN is not recommended as there will be no cleaning action and weld will have porosity.

ER5356 vs ER5183

Both ER5356 and ER5183 are aluminum-magnesium base TIG-MIG filler wire rods for Aluminum welding.

The main difference between ER5356 and ER5183 is the manganese amount. ER5183 contains higher manganese (0.50- 1.0%) compared to ER5356 (-.05- 0.20%).

ER5356 has higher weld strength compared to ER5183 welding wire.

ER5356 or ER4043: Which one is suitable for you?

ER4043 and ER5356 are aluminum welding wires that have different properties.

- ER4043 is a Silicon-Aluminum base wire while ER5356 is Magnesium-Aluminum base wire.

- ER4043 has a low melting point but higher molten pool fluidity compared to ER5356 wire.

- ER5356 welding wire is suitable for anodizing after welding however ER4043 does not suit after weld anodizing weld applications.

- ER5356 is a magnesium-containing wire that has a higher weldability, higher welding strength and better ductility. It is best used for welding thicker sheets of aluminum.