Welding of 6061 aluminum is carried out using ER5356 and ER4043 type Filler wires. But out of these two filler wires, which one suits best for your application?

In this post, you will find detailed information on the Welding of 6061 aluminum grade, its properties and its uses.

Is 6061 aluminum weldable?

Yes, 6061 aluminum is weldable using the TIG or MIG welding or Aluminum Brazing process. If you’re not experienced in welding, it’s best to consult with a professional before attempting to weld 6061 aluminum.

Check out the complete recommendation in this post for welding 6061 aluminum successfully.

👉👉👉👉👉 Check these Aluminum Welding Tools 👉👉👉👉👉

What is 6061-T6 Aluminum?

Aluminum grade 6061 is aluminum alloyed with Silicon & Magnesium as the main alloying element. The UNS Number of Grade 6061 is A96061. The P Number as per ASME Section IX for 6061 aluminum is P No. 23. The alloy is used in general aluminum structures, railway parts, and aerospace applications.

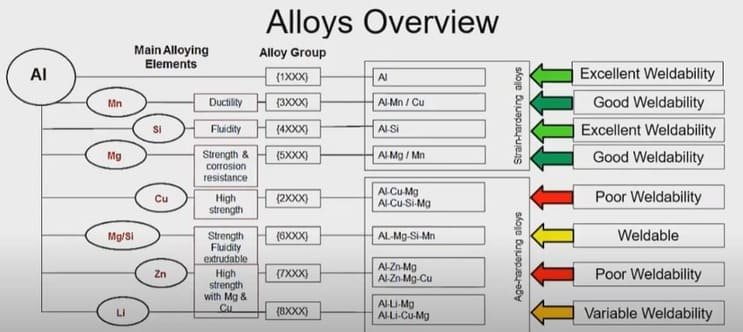

The below diagram gives an overview of general aluminum alloys.

Classification of aluminum grades

The aluminum alloys have a naming system that has a high level of international recognition. It has a four-digit base:

Pure alloys: 1xxx

Aluminum- copper alloys 2xxx

Aluminum -manganese alloys 3xxx

Aluminum – silicon alloys 4xxx

Aluminum – magnesium alloys 5xxx

Aluminum – magnesium- silicon alloys 6xxx

Aluminum – zinc alloys 7xxx

What are the Chemical properties of 6061-T6 aluminum?

The chemical composition of Al 6061 material as per the material specification is given in the below table for reference.

| Al | Mg | Si | Fe | Cu | Cr | Zn | Ti | Mn | Remainder |

|---|---|---|---|---|---|---|---|---|---|

| 95.85 – 98.56 | 0.8 – 1.2 | 0.40 – 0.8 | 0.0 – 0.7 | 0.15 – 0.40 | 0.04 – 0.35 | 0.0 – 0.25 | 0.0 – 0.25 | 0.0 – 0.15 | 0.05 each, 0.15 total |

Physical properties of 6061-T6 aluminum

The physical properties of 6061 alloy that affect the weldability of aluminum are density, it’s melting points, and thermal expansion are given in the table for reference.

| Physical Property | Value |

|---|---|

| Density | 2.70 g/cm³ |

| Melting Point | 650 °C |

| Thermal Expansion | 23.4 x10^-6 /K |

Properties as per the Spec: BS EN 755-2:2008

| Mechanical Property | Value |

|---|---|

| Proof Stress | 240 Min MPa |

| Tensile Strength | 260 Min MPa |

| Hardness Brinell | 95 HB |

TIG/ MIG Filler wire for 6061-T6 Welding

Welding of 6061 aluminum grade or also called 6061-T6 is welded using ER5356 & ER4043 and both filler wires can be used to weld Aluminum 6061 grade.

1. ER4043 (GTAW/GMAW) – ER4043 is a silicon alloyed (5%) aluminum TIG wire used for welding of 6061 grade. The wire offers very good weld fluidity with a good weld appearance.

ER4043 is not used for welding applications where the weld is subjected to high shear stresses. It is having lower shear strength than the ER5356 filler wire.

| ER5356 X 3/32″ X 36″ X 1LB Tube high strength aluminum TIG welding rod |  |

| YESWELDER Aluminum TIG Welding Rod ER4043 1/16″x16″ 5LB |  |

ER4043 is used with pure argon shielding gas & Alternating current (AC) and pulsed current polarity for TIG & MIG welding applications. The AWS specification for ER4043 is AWS A5.10.

F-Number of ER4043 is 23.

ER5356 (GTAW/GMAW) – ER5356 filler wire offers good strength and weld ductility compared to the ER4043 type. ER5356 is a widely used TIG/MIG filler rod and has many uses. It can be used with DC Reversed Polarity and pure Argon shielding gas to be used for shielding purposes. F-Number of ER5356 is 22.

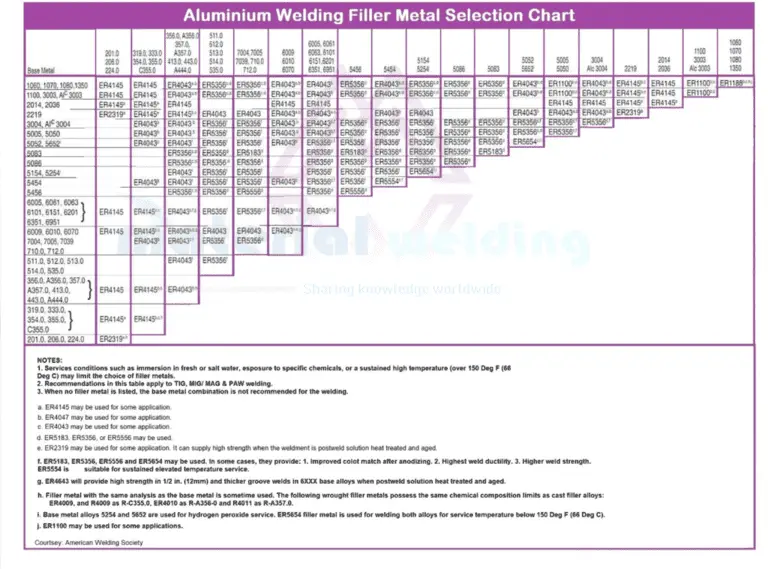

Selection of welding consumables for Aluminum Welding

The best filler rod for TIG or MIG Welding of 6061 aluminum is ER5356 and ER4043. Also, you can use this chart to find the best suitable GTAW/ GMAW filler wire to weld the various grades of Aluminum.

Hot cracking can be prevented by using 4043 type filler wire, but it will give lower ductility and toughness compared to 5356 type wire. 4043 types due to high silicon content give a poor color match to 5XXX and 6XXX aluminum base metals after anodic oxidation treatment.

When welding 5XXX (high Mg, more than 3% usually), 4043 is a poor choice as it will make an intermetallic compound of mg2Si in the weld metal. This will lower the weld metal ductility and increase its crack sensitivity.

Click here to see a large-size image.

Which Welding process is best for 6061 aluminum welding?

Welding of 6061 aluminum can easily be carried out using TIG and MIG welding. GTAW or TIG welding is used for welding sheet metal and thin parts using AC polarity along with pulse current.

AC welding gives cleaning action in the welding arc that helps to automatically clean the oxide layer from the aluminum surface.

MIG welding is used for welding of heavy thickness. More advanced welding processes such as friction stir welding and laser welding are used a lot in aerospace applications and other aluminum welding applications.

Stick Welding can also be succesfully used to weld aluminum. For a good weld, consider proper welding rod sizes and amperage selection.

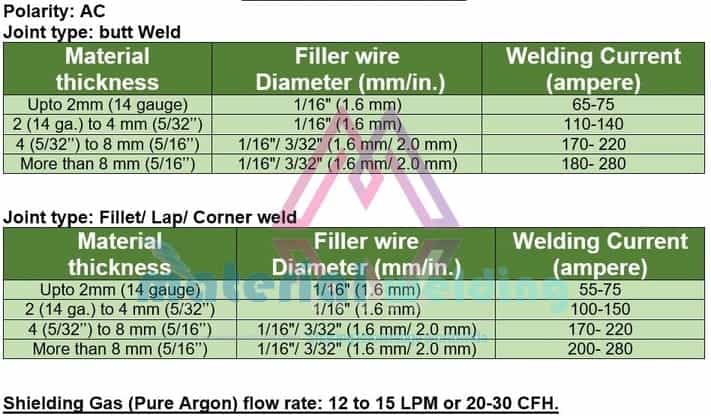

TIG Aluminum Welding Parameters

When welding aluminum with the TIG process, the weld puddle will be very fluid. It’s important to use the correct welding parameters to produce a strong, durable weld. The following are some tips for welding aluminum with a TIG welder:

- Use a small-diameter tungsten electrode (1/16 inch or less). A smaller electrode will help create a more stable weld puddle.

- Use a shielding gas mixture of 75% argon and 25% helium. This mixture will help prevent oxidation and contamination of the weld puddle. You can also use Pure Argon Gas Shielding.

- Adjust the welding current accordingly. For most applications, a current setting of between 110 and 250 amps should be sufficient.

- Adjust the welding voltage according to the thickness of the material being welded.

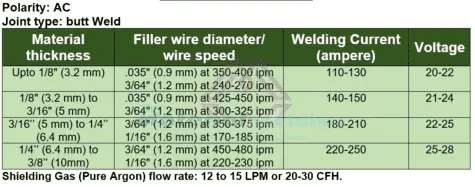

TIG welding Parameters for Aluminum welding are given in the below table for reference.

MIG Aluminum Welding Parameters

MIG aluminum welding is a process that welders use to join pieces of aluminum together. In order to achieve the best results when welding aluminum, it is important to set the proper welding parameters.

The most important parameter to set is the weld voltage. The weld voltage affects the size of the weld puddle, so it is important to find the right setting for your particular application.

Other parameters that need to be set include the wire feed speed and the gas flow rate.

When welding aluminum, it is important to use a wire feed speed that is slow enough to allow the weld puddle to form properly, but not so slow that the weld puddle will solidify before it can be deposited into the joint.

The other key parameters when welding aluminum are voltage and amperage. These should be set according to the thickness of the material being welded.

For example, when welding 1/8 inch thick aluminum, the voltage should be set at 21 volts and the amperage should be set at 140 amps.

Shielding and Backing Gases for Aluminum welding

Pure Argon is widely used. Argon-Helium mixture in TIG/ MIG welding. Helium addition helps for a better weld formation and increases the welding speed.

Helium also minimizes the risk of pores and lack of fusion. Pure helium is not used due to the high Ionisation potential of the gas as well as the high cost of the gas.

The gases used for shielding of AL6061 are argon, helium, or a mixture of the two. Both provide sufficient oxidation protection. The choice depends on which of the various gas properties are required for the best weld.

The significant properties are:

a. Density: The lighter gas is more likely to be blown away

b. Ionization Potential: The gas should have a higher ionization potential for ease in arcing.

c. Thermal conductivity: The gas with the higher thermal conductivity gives the widest weld bead (due to conductivity over the surface)

d. Cost: Helium has to be imported and is expensive. Argon is extracted from the air by normal liquefaction processes.

e. Moisture Free: The gas must also be free of moisture and hydrogen. The most usual gas is an argon-helium mixture.

Preheating for 6061 Aluminum:

Preheat for welding of 6061 aluminum is recommended for thicker sections or whenever sufficient penetration can not be achieved due to the high thermal conductivity of the aluminum.

So, if any of the above issues are faced, a preheat temperature of 150 to 200°C can be applied. Also, when repairing 5XXX (Al-Mg) grades, it can crack in the weld or HAZ area.

Following a preheat in these conditions is very beneficial to mitigate the cracking inter-alia by using the right filler wire.

Watch our YouTube video to Learn what is Preheat, Inter-pass & post-heating.

Interpass Temperature:

Usually, the interpass temperature is kept above the minimum preheat temperature for the Welding of 6061 aluminum.

Weldability of Aluminum Alloys

Weldability is the combined effect of many variables. These relate to:

- The difficulty of melting: Factors concerned are: melting point, heat capacity, heat radiation effect, and thermal conductivity effects.

- Distortion problems: These are influenced by thermal expansion and thermal conductivity inter-relations. The possibility of phase changes that can give other density changes must also be considered.

- Chemical reactions: The predominant problems here are the effect of oxidation and the possibility of a gas solution. With aluminum, the residual oxide film can also give problems.

- Cracking tendency: Some alloys have a particular tendency to crack and special attention has to be paid to minimizing this.

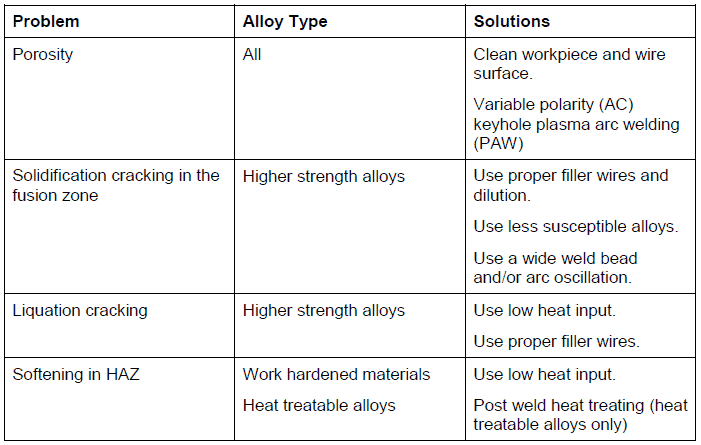

Cracking in 6061 Aluminum grade

Cracking in 6061 aluminum can be solidification cracking in the fusion zone or liquation cracking. To avoid cracking in aluminum welding of 6061 or other grade use:

- Use proper filler wires and dilution.

- Use less susceptible alloys.

- Use a wide weld bead and/or arc oscillation.

- Use low heat input.

Conclusion:

In conclusion, the Welding of 6061 aluminum is possible with both the tig and mig welding processes. When using the tig process, a filler metal is not typically necessary, making it a popular choice for welding thin sheets of aluminum.

The mig process is more commonly used for welding thicker pieces of aluminum, as it produces a stronger weld. Both processes produce a high-quality weld when done correctly.