Heat Input in Welding is an important factor for the resultant weld deposit properties. So, it is crucial to use the right Welding Heat Input Formula for the calculation to accurately predict the total heat input.

Heat Input in Welding, and how to calculate it?

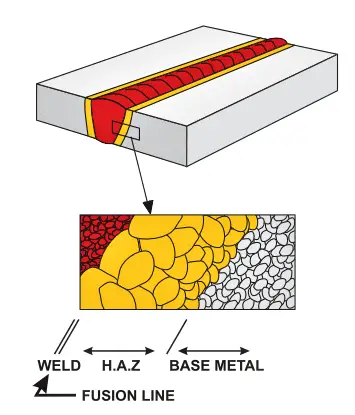

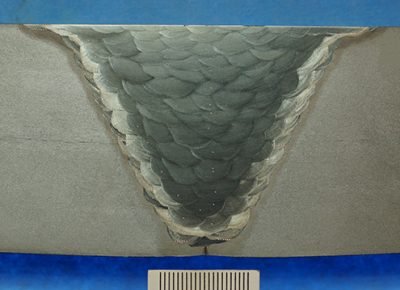

The heat input in welding influences the weld cross-sectional area. High heat input welds have a large weld bead and commonly for submerged arc welding, achieve high dilution; the associated slow cooling results in austenite grain growth in the HAZ, giving low toughness.

Heat can be technically transferred into the matter in three different ways depending on the aggregate state of the material:

- Conduction

- Convection &

- Radiation

In welding joints, most of the heat transfer takes place by conduction. Not all of the 100% heat is transferred to the weld pool due to heat losses taking place during heat transfer.

Unit of Welding Heat input

Units of welding heat input are:

- Joules/ mm

- kj/mm

- joules/inches

- kj/inches

Effect of heat input in welding on mechanical properties

Heat Input Formula & Calculation in ASME Section IX & AWS D1.1

Heat input is considered as a Supplementary Essential variable in the BPVC ASME Section IX.

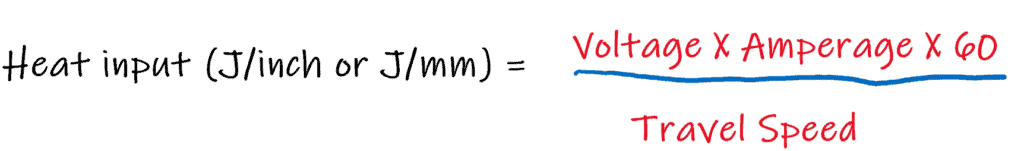

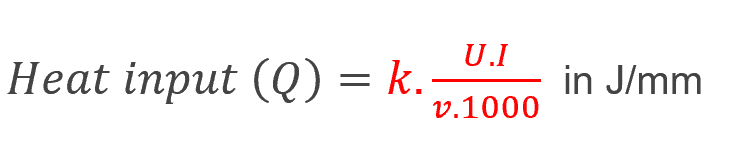

Heat Input Formula

The heat Input Formula takes into consideration factors resulting in heat input during welding and the heat Input Formula is given as:

Heat Input Formula (J/inches) = (Voltage X Amperage X 60)/Travel Speed

So, for a WPS requiring CVN testing/ toughness, the increase in heat input shall be considered as the Essential Variable. Clause QW 409.1 is applicable to SMAW, GTAW, GMAW (MIG-MAG), SAW, FCAW, PAW & EGW processes and shall be determined:

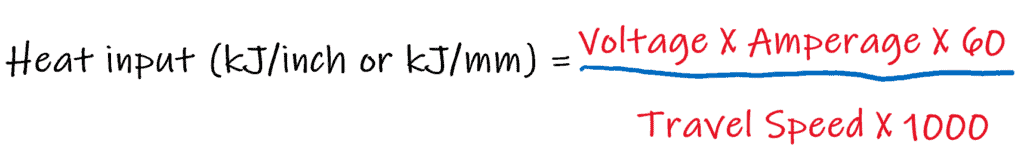

Heat Input Formula kJ/mm & kJ/Inch

Heat Input Formula in kJ/mm & kJ/Inch is given as:

Heat Input = (Voltage X Amperage X 60)/Travel Speed x 1000

Where travel speed is in inch/ minute or mm/min. Using a dividend factor of 1000, the heat input value obtained will be in kJ/inch or kJ/mm as shown below:

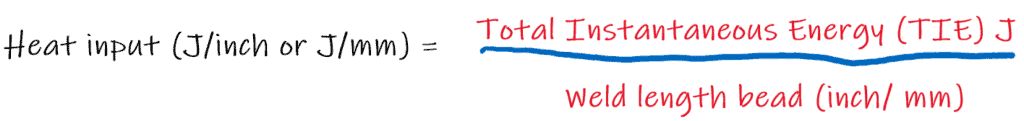

AWS D1.1 2020 Edition, clause 6.8.5 uses the same equation as in ASME Section IX given above. For waveform-controlled welding processes, heat input shall be determined by following Heat Input Formula:

Heat Input Formula = Total Instantaneous Energy in Joules/ weld bead length in mm or inches

Heat Input Calculation in Welding with Example:

Welding heat input calculation with example is given for the welding process here.

1. Calculate the heat input for a procedure qualification test coupon welded with a current range of 140A to 190 Amp, 16-18 Volts, and travel speed of 80 mm/min to 110 mm/min.

Solution:

Considering the practical situation here in this example, the heat input shall be having two values:

- Minimum heat input

- Maximum heat input

For minimum heat input we will take the current and voltage on the lower side as it’s a multiplication factor, and travel speed on the higher side as travel speed is the dividend factor. So the Heat Input Formula will be:

Minimum Heat input (J/min) = (140 X 16 X 60)/110 = 1221.8 J/min or 1.22 kJ/mm

Whereas, the

Maximum heat input (J/min) = (190 X 18 X 60)/80 = 2565 J/min or 2.57 kJ/mm

Here, the unit of travel speed is inches, the heat input will be in Joules/inch or kJ/inch.

Heat input Formula Calculation according to ISO/TR 18491:2015 or EN 1011-1

When a WPS/ PQR qualification is carried out according to ISO/ BS/ EN or DIN standards such as DIN EN ISO 15614-1, the heat input shall be determined by the following heat Input formula:

Where

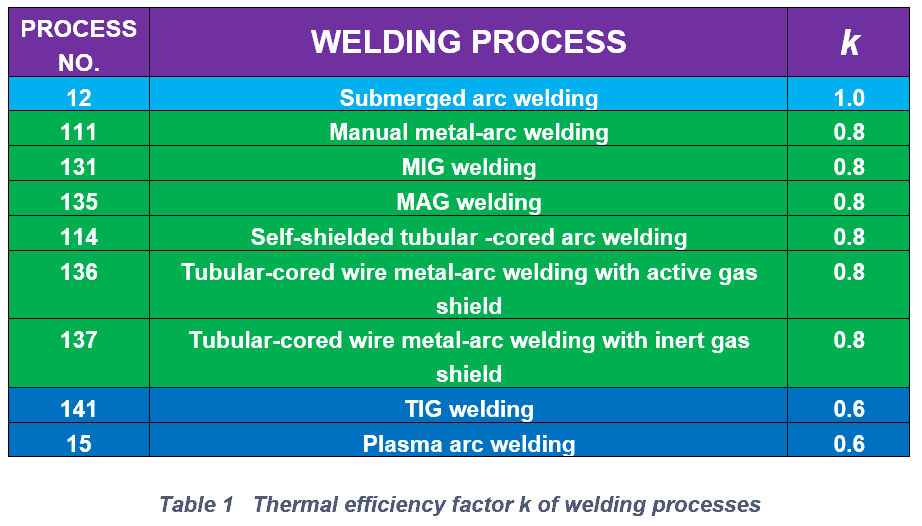

k is the thermal efficiency for the welding process given in Table 1;

U is the arc voltage measures as near as possible to the arc, in Volts;

I is the welding current, in Ampere;

V is the travel speed in mm/s.

Importance of Heat Input

For most of the carbon steels, low alloy steels, Cr-Mo steels as well as stainless steels, abrupt cooling from the heat of the welding is avoided. Because of the risk of hardening, cracking, change in the weld metal and HAZ microstructure, etc.

Depending upon the type of material, its thickness, and heat input, the maintenance of a lower preheat temperature and upper inter-pass is required. For such materials, heat input shall be chosen to be matched to the welding process.

The heat input during welding is one of the main factors affecting the properties of ferritic (e.g. SS410) and Duplex stainless steel. This influences the time/temperature cycle occurring during welding and results in inhomogeneity in the microstructural phases.

What is Heat Affected Zone or HAZ in Welding & HAZ width?

How to Control Heat Input in Welding?

Welding heat input is a product of Voltage and Current divided by travel speed. So, to control the welding heat input, it is essential to keep the value of current and voltage on the lower side while travel speed should be kept high.

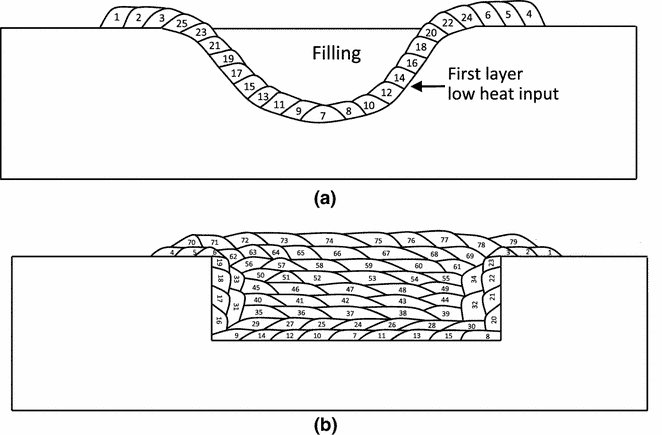

Similarly, the welding shall be carried out by stringer beads as they help to keep the travel speed faster. Weaving reduces the welding travel speed and hence increases the welding heat input.

If possible, carry out the welding with a lower diameter rod as they need lower welding amperage so it will indirectly reduce the welding heat input.

Apart from the above, using advanced welding techniques such as pulsed TIG and MIG welding is also beneficial for controlling the welding heat input.

Read more:

- Determination of the gross heat input in arc welding

- Explanations heat input

- The ABC’s of Arc Welding