What is a Tack Weld & its Importance?

Tack welding is used extensively in fabrication and is the main element of a welded structure. Good quality tack welds are the backbone of a fabrication structure, piping spool integrity & dimensional stability.

Tack Welds is similar to a quick air quench application. It can result in a brittle and crack-prone weld microstructure such as martensite and upper bainite in low alloy and Cr-Mo steels.

Hence, a suitable and right procedure should be implemented for tack welding which includes preheating before tacking and making tack weld of sufficient length.

Tack welds have 2 types based on how they are applied in a weld joint:

- Temporary tack weld: When a tack weld is used to make a temporary weld joint fit-up/ weld conditions with a nonqualified tack welder (e.g. fitter), such tack welds lack surety for quality & must be grinded away before filling the weld joint.

- Incorporated tack weld: These types of tack weld are welded by a qualified tack welder & are not grinded. After finishing the part fitment, these tack welds are fused in the welding and hey become part of the weld.

The minimum and the maximum length of a Tack weld:

The minimum length of tack welds shall be 50 mm (2 inches) for incorporated tack welds. The reason for having a minimum of 2 inches as a smaller tack weld will not provide sufficient heat into the base metal thus there is a high propensity for lack of fusion issues.

This is due to the fact that tack welds smaller in length (less than 2 inches) are having a high risk of lack of fusion problems.

The reason is- welding small tacks will result in rapid heat dissipation & there will not be adequate welding heat input to make a sound tack weld deposit.

Temporary tack welds can be as small as 10 mm (3/8 inch.) as long as they are sufficient to withstand the stresses due to the weld fit-up.

As these types of tack welds are to be removed before filling the joint, any issue of lack of fusion or penetration shall be taken care of by the subsequent weld pass.

The minimum tack weld length as given by Japanese Architectural Standard Specification (Number: JASS 6), is given in the below table.

| Recommended min. tack weld length | |

| Material thickness (mm) | Min. weld bead length (Inches) |

| Up to 1/4 inches | 1.25 |

| > 1/4 inches | 1.75 |

what should be the length of tack welds on fillet welds

The length of fillet weld can be somewhat lower than compared to groove welds. The reason for the shorter tack length is due to less stress in fillet welds compared to groove welds.

Generally, a tack weld length of 10 mm is good for incorporated tacks in the fillet weld. Tack welds that need to be ground should have a length of 1-inch minimum.

A general standard practice of minimum tack length can be followed as shown in the above table.

Tack Weld & Tack Welder definition?

What is a Tack Weld: tack weld is a type of weld placed on a job to hold different parts (e.g. plate, pipe, bar) of a welding joint in their right alignment at fitting stage to their final weld completion. Tack welds are usually removed before making a weld or sometimes they are fused within the welding also.

Who is a tack welder? A Tack welder is a person who performs small-length welds (tack welds) to hold the parts during the fitment stage in the right alignment. Final welding is carried out by the welder over these tack welds or by removing them.

Tack Welders. ASME BPVC Section I, VIII & B 31.3 requires that the tack welding procedure to be qualified in accordance with the referencing code section i.e. ASME Section IX.

Tack welds welded for groove weld root must be qualified by a groove weld test as per the ASME Section IX. Tack welds used for fillet welds can be qualified by a groove test or fillet test according to the ASME Section IX requirements.

As per AWS D1.1, Tack welders are welder who has successfully passed a tack welding WQT (Welder Qualification test) as per the requirements of the D1.1 Code.

Such qualified tack welders are eligible to make tack weld on the jobs within the qualified range based on the fillet weld WQT used for the qualification. This qualification remains valid unless there are any concerns that question the skills of the tack welder to make a good quality sound weld.

Further According to AWS D1.1, clause 6.2.2 related to welding personnel Performance Qualification: The test requirements for tack welder are given in the D1.1 Code, Part-C. This part has given all the requirements related to WQT Size, range, test requirements and other qualification details for all welding processes that are permitted by the code.

Example processes are: SMAW or Stick Welding, FCAW, GMAW, TIG welding, EGW, SAW etc.

How tack welder shall be qualified & tack welding procedure?

According to AWS D1.1, clause 6.16.1.20 Tack Welders states that A tack welder will be qualified using one test coupon in each welding position for tack welding has to be carried out.

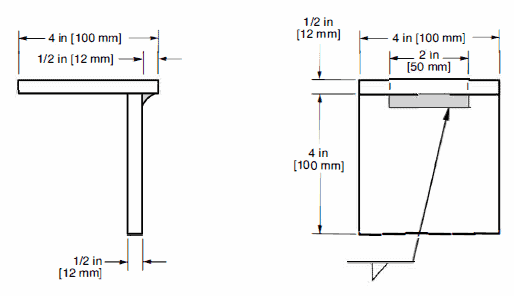

Every tack welder shall weld a fillet size of 1/4 inch or 6 millimeters of maximum tack weld size around 2 inches or 50 millimeters in length using a tack weld WQT for fillet break test.

Acceptance of Tack Welder qualification

According to AWS D1.1, clauses:

6.24.1 Visual Acceptance Criteria. The tack weld shall have a good weld profile and be free from cracks, overlay, and undercut exceeding 1/32” or 1 millimeter. The weld shall be free from any visible surface pore or porosity.

6.24.2 Destructive Testing Acceptance Criteria. The test coupon after fracture shall show root fusion, and there shall be no lack of fusion (Incomplete fusion), inclusion, and weld porosity greater than 3/32” or 2.5 millimeters.