Welder Performance Qualification (WPQ) in AWS D1.1

The performance qualification tests (WQT) given by this code are specifically designed performance tests to evaluate the welder’s, or welding operator, or tack welder’s skills to weld a sound welds.

The performance qualification system is not a guide to the welder for actual production welding and a qualified WPS should be followed for welding guidance on production welds.

A WPS contains all the essential welding variables that are responsible for the mechanical strength and other properties of the welding joint.

AWS D1.1 requirements welder/ welding operator qualification & certification in two ways:

- Non-Tubular Sections

- Tubular Sections

AWS D1.1 2020 Edition, Section 6: Qualification, Part-C Performance qualification lists the requirements for welder/ welding operator qualification for non-tubular applications.

Tack Welders: The qualification of a tack welder as per AWS D1.1 is carried out by welding one test coupon for each welding position for which tack welding is to seek.

Types of Test Required for Welder qualification as per AWS D1.1

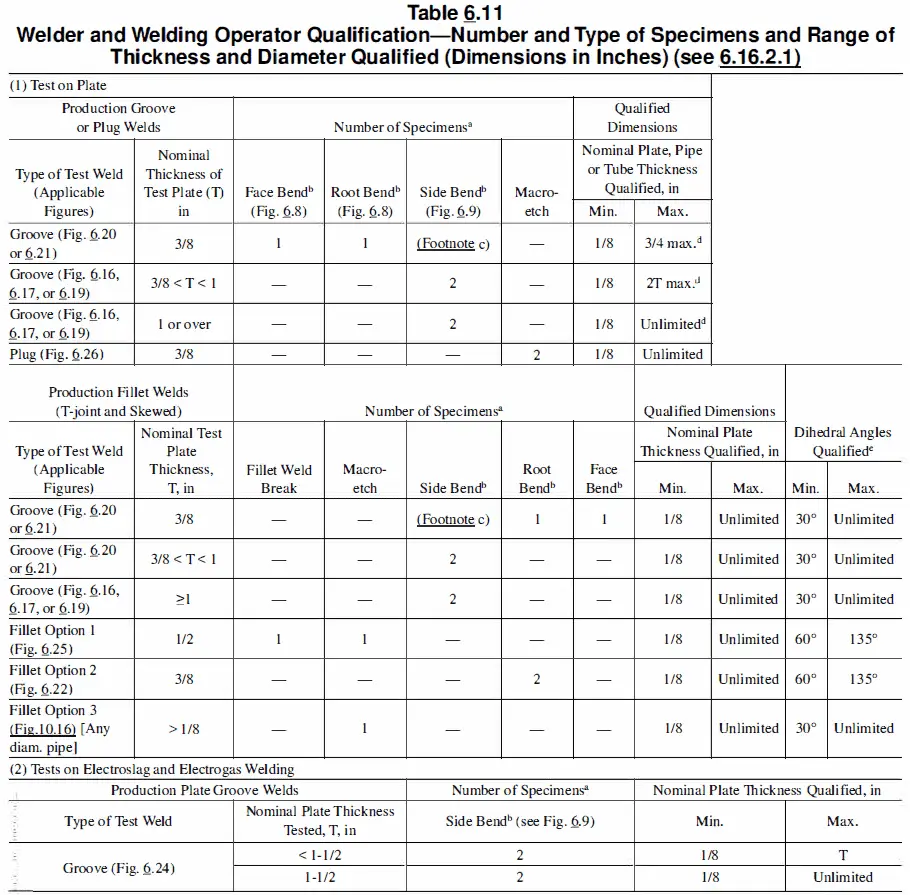

The type and number of qualification tests required for welders/ welding operators are given in Table 6.11 of AWS D1.1.

The standard test used for welder testing are:

AWS D1.1 allows substituting Radiographic testing in place of bend test as highlighted in AWS D1.1, clause 6.17.1.1-Substitution of RT for Guided Bend Tests.

As per D1.1, Except for weld test specimens welded by GMAW-Short-circuit mode, RT of a welder or welding operator qualification test plate or test pipe may be used in place of bend tests. An excerpt of AWS D1.1, Table 6.11 is given below for reference.

Here, as allowed you can substitute the bend test with RT. So, for groove weld, you will need to do a visual inspection and RT to qualify a welder as per AWS D1.1.

Welder qualification test acceptance criteria as per AWS D1.1

Visual Acceptance Criteria

Visual testing for WQT shall be performed according to the AWS D1.1, clause 6.10.1-For Visual Inspection (VT) of Welds. This clause also covers the acceptance criteria for the VT. The criteria are given for:

For groove weld, the VT acceptance is as below:

- Cracks are not acceptable of any size.

- Weld craters must be filled o match the weld.

- Weld reinforcement height shall not be more than 1/8 inches (3 mm).

- The maximum Undercut allowed is 1/32 inches (1 mm) as per AWS D1.1.

- Free from Lack of fusion, cracks, or insufficient joint penetration for the CJP groove root.

- CJP weld on groove without backing- single-side welded, following is the acceptance for root concavity and melt-through type welding defects:

(a) The weld root concavity must not be more than 1/16 inches or 2 millimeters, condition to that the weld throat size is same or more than the base material thickness.

(b) The melt-through at the weld root must not be greater than 1/8 inches or 3 millimeters.

For fillet weld, the VT acceptance is as below:

(1) Cracks are not acceptable.

(2) All weld craters should be filled sufficiently.

(3) Leg Length size shall be checked as per the drawing requirements for all fillet welds.

(4) Fillet weld visual shall be checked as per Figure 1.4. of AWS D1.4.

(5) The maximum size of the undercut shall be 1/32 inches or 1 millimeter.

Bend Test Acceptance Criteria

Bend Test (Root, Face, and Side Bend Specimens) the acceptance is given in AWS Code D1.1, clause 6.10.3.3. The explanation of AWS D1.1 bend test acceptance criteria is given below:

The convex face of the bend test coupon shall be VT examined for surface imperfection. To accept the bend test result, the bending surface of the specimen shall not show any discontinuities more than the following:

(1) maximum permitted discontinuity size is 1/8 in [3 mm] on any side of the surface.

(2) 3/8 inches or 10 millimeter-the total of the highest sizes of all discontinuities are more than 1/32 inches or 1 millimeter, but less than or equal to 1/8 inches or 3 millimeters.

(3) The maximum size of any crack is 1/4 in [6 mm] unless it can be established that the crack is due to any slag inclusion or other fusion issues, then the maximum size allowed will be 1/8 inches [3 mm].

Bend coupon showing corner crack more than 1/4 in [6 mm] with no indication of slag inclusions or other fusion type defects shall be ignored, and a new bend specimen shall be made from the actual welder test coupon.

Radiographic Acceptance as per AWS D1.1 for welder/ operator qualification

Acceptance Criteria for welder/ operator qualification radiographic test is given in AWS D1.1, clause 8.12.2 and as follows for welder test (WQT) acceptance:

- Cracks are not acceptable.

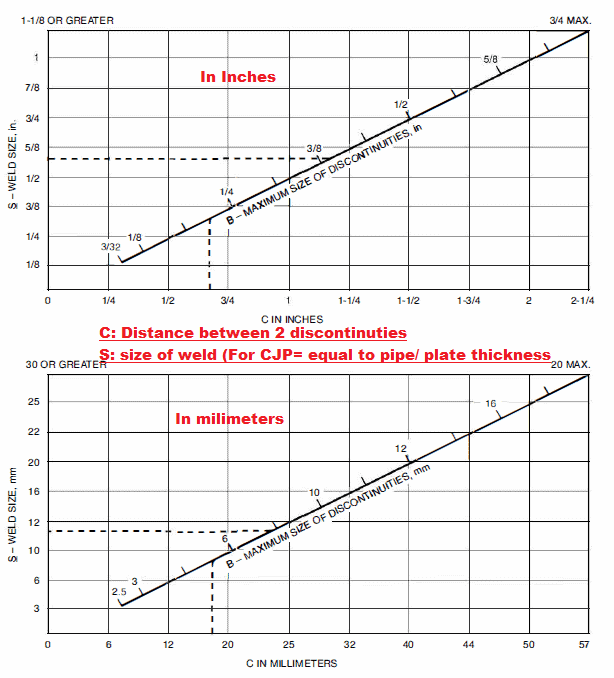

- For other discontinuities, the acceptance is based on the combination of weld size and distance between two defects.

Rounded discontinuities greater than a maximum size of S/3, not to exceed 1/4 in [6 mm]. However, when S. is greater than 2 in [50 mm], the maximum rounded indication maybe 3/8 in [10 mm].

Macro test Acceptance Criteria

The macro etch specimens shall meet the following acceptance at a minimum:

(1) Fillet welds shall show complete root fusion.

(2) The Fillet Weld Leg length Size shall be acceptable as per the drawing requirements.

(3) Plug welding inspection shall ensure that:

(a) There are no cracks in the weld.

(b) Shows complete fusion to the backing.

(c) No visible slag in excess of 1/4 inches or 6 millimeters total accumulated length.

Similar Posts:

- Porosity in welding causes, remedies

- Weld Testing Methods & welding Test Types

- Lack of Fusion in Welding-Causes-Remedies

- Welding Undercut- causes & Remedies

- How to be a Certified Welder?

- What is the Welder qualification test WQT acceptance criteria for ASME Section IX

- What is 6GR welding Test position? 6GR welding test tips and welder qualification

- What shall be the minimum & maximum length of tack welds & qualification requirements for Tack Welder?