Welding Procedure Specification- WPS

In this post, I have provided detailed guidelines on the qualification of WPS & PQR for weld overlay deposit for corrosion resistance overlay (Also called CRO) and hard facing or wear-resistance weld overlay.

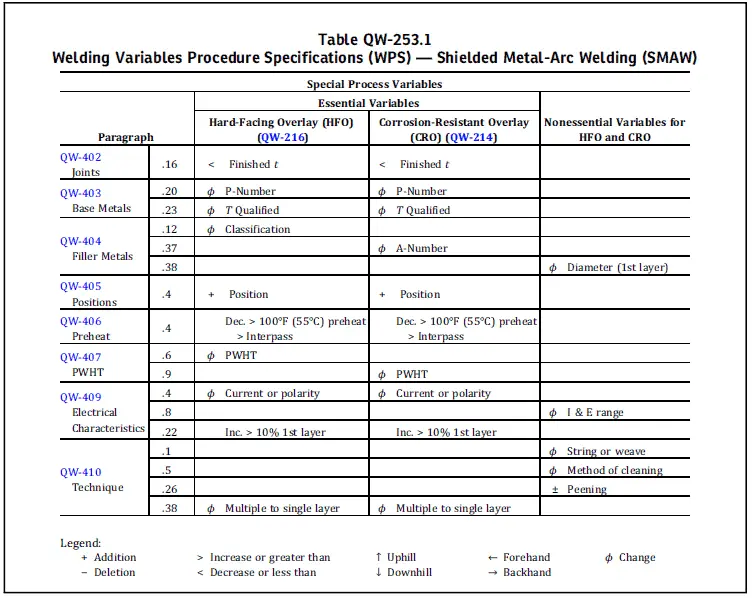

The Welding Variables differ for weld overlay applications and are specified in ASME Section IX under Special Process Variables. See below Variables in ASME Section IX for SMAW weld overlay qualification (Table QW 253.1).

The variables are not the same as what is being considered in general SMAW WPS qualification as listed in Table QW-253.

Click here to Learn about Essential, Non-Essential & Supplementary Essential Welding Variables.

The post is written to cover this qualification according to the ASME Section IX.

Click here to Learn How to write a WPS.

Steps for WPS-PQR qualification (Procedure Qualification)

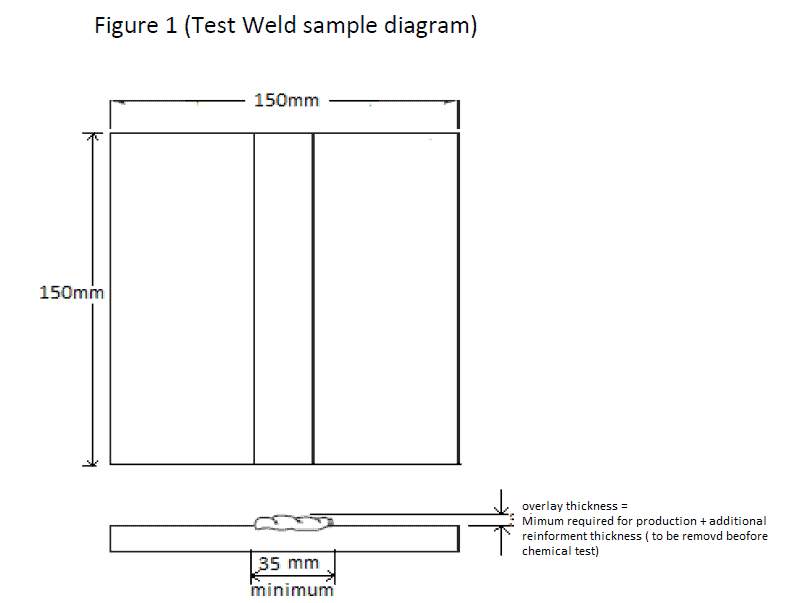

- Review and choose the test specimen type (Plate or pipe) and its size (base metal thickness based on job requirements), Minimum test sample size is 150 mm X 150 mm (6 inches x 6 inches).

- Preclean, trial run, and welding conditions to prepare before welding actual test coupon.

- Perform the welding on the test coupon. The minimum width of the weld deposit for the overlay is 38 mm or 1.5 inches. Record all the details in the PQR.

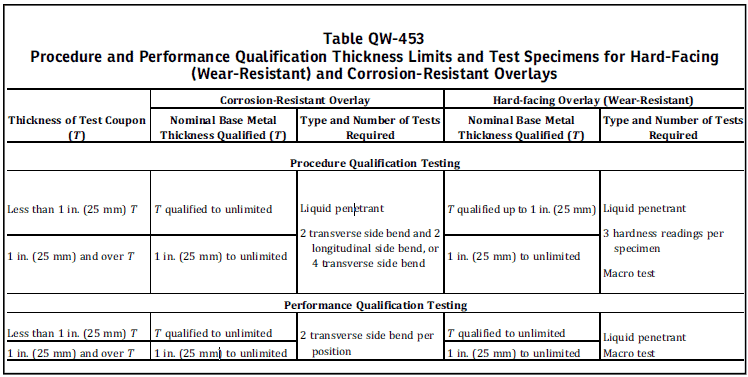

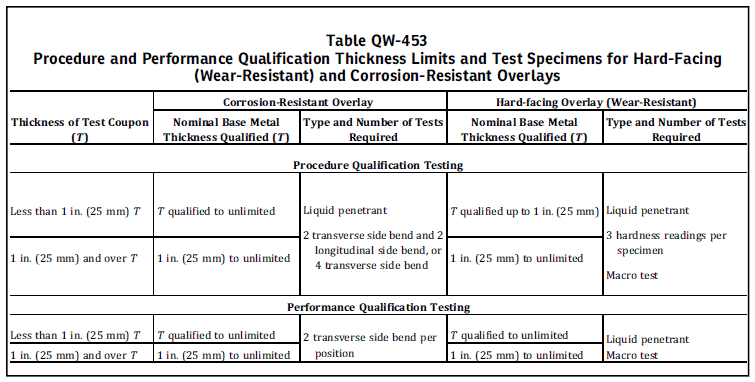

- Perform the Mechanical tests as per ASME Section 9 Table QW-453 given below.

- Make a Procedure qualification record or PQR listing out all the variables (Essential, Non-essential & supplementary) for the welding process used.

- Perform the review of PQR. If any third-party inspection or client witness is involved, let them sign on it. The same applies to the next point.

- Prepare & issue the WPS covering the qualified range of welding parameters.

Steps for Welder/ operator Performance Qualification (WPQ)

You have the freedom to use the same test coupon (PQR qualification) for welder/ operator performance qualification as per the ASME Section IX.

Hence, to save the time and cost of the qualification. follow the below steps:

- Review the minimum test requirements for welder/ operator performance qualification as given in Table QW-453.

- Based on the test results, thickness used, and welding parameters range permitted, issue the welder/ operator (WPQ) certificate.

- For any additional welders/operators- you require to weld additional test coupons with the limit given in the qualified WPS earlier.

- Execute the NDT and destructive test as given in table QW-453.

- If all tests are accepted, issue the welder certificate or WPQ.

Thickness for PQR Qualification Test Coupon

For Tube sheet: For tubesheet PQR coupon, the thickness shall be equal to a production job minimum thickness or 2 inches (50 millimeters)- any of which is smaller shall be used.

For Plate: For Plate, test specimen thickness shall be equal to a production joint minimum thickness or job requirements. The thickness limit qualified Table QW-453.

Test coupon preparation

The test coupon for PQR Qualification shall use the same material specification as required for the job. This includes having the same P No. & group no. if applicable.

Prepare the test coupon as per the dimensions suggested in the below picture. The standard coupon size as per ASME Section IX is 6 inches X 6 inches X minimum production joint thickness.

The width of the weld deposit on the test coupon shall be minimum of 1.5 inches or 38 millimeters.

Weld overlay PQR qualification test requirements

For a WPS-PQR qualification (Procedure qualification) as per ASME Section IX, the minimum testing requirements & range of thickness qualified are given in Table QW-453, abstract given below.

The table also covers welder qualification or performance qualification tests requirements for weld overlay & hard facing.

The main tests requires for Weld overlay- hard facing or corrosion-resistant overlays as per ASME Section IX are:

- Tests required for CRA weld overlay

- Visual Inspection– Mandatory for any PQR/WPS qualification

- Penetrant testing for surface NDT.

- 2 transverse & 2 longitudinal bend tests. This can be replaced with 4 side bend tests as per the thickness limit allowed in ASME Section IX.

2. Tests required for Hard facing overlay (wear-resistant)

- Visual Inspection- Mandatory for any PQR/WPS qualification.

- Penetrant testing for surface NDT.

- Macro test.

- 3 hardness measurements per sample.

Penetrant Testing Acceptance Criteria for PQR qualification

Acceptance based on Relevant indications: Any penetrant testing indications having main dimensions more than 1.5 millimeters or 1/16 inches shall be considered as relevant indications.

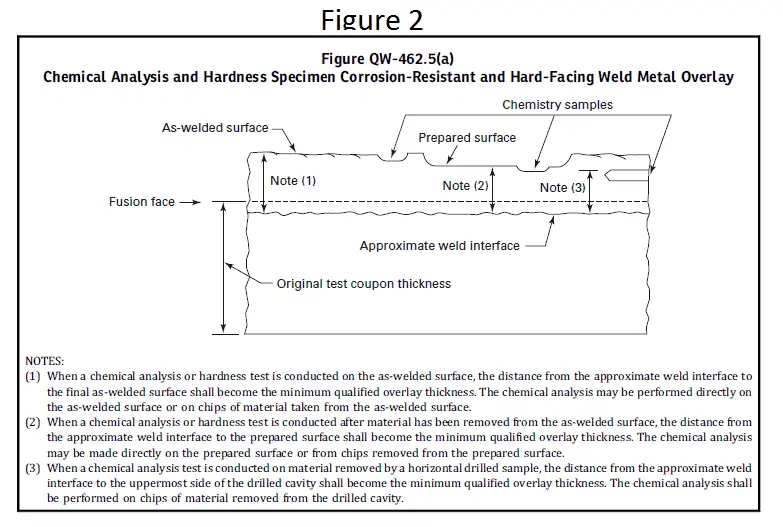

- For weld overlay weld metal chemistry analysis WOL thickness qualified by the PQR, See below figure from table QW-462.5 (a), ASME Section 9.

Bend Test Acceptance Criteria

During the evaluation of the bend, the test coupon must ensure that the HAZ & weld in the transverse bend coupon shall be covered inside the bend area of the test coupon after bending. This will ensure that there is full coverage by the bend test for the area of interest that could have any welding-induced flaws.

Further to above, all guided‐bend coupons will show no open flaws in weld/ (HAZ), more than 3 millimeters or 1/8 inches on the bend specimen after bending on the convex side of it. Any flaws less than 1/8 inches or 3 mm shall be acceptable and no reason for the rejection of the test.

Any open flaws visible on the bend test coupon at the corners will not be a cause for the rejection except if there are any concerns or proof that these flaws are due to any inherent welding defects such as LOF, slag inclusions & any other defects that were there.

For CRA weld overlay there shall be no open defects more than 1.5 millimeters or 1/16 inches shall be acceptable for the cladding, & no open flaws more than 3 millimeters or 1/8 inches shall be allowed along with the close weld interface.