Hard Facing

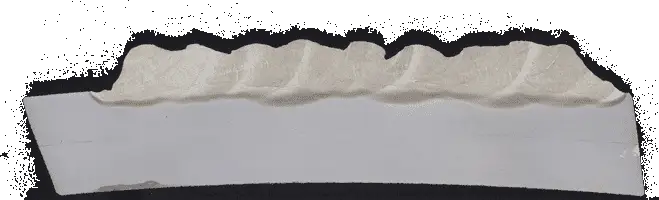

Hard facing is a type of welding that involves depositing a wear-resistant layer on a less wear-resistant metal.

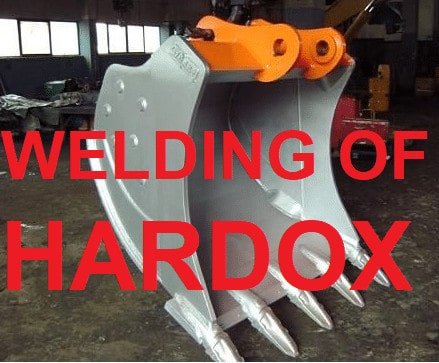

The purpose of hard facing is to extend the life of the base metal by protecting it from wear, abrasion, or corrosion (e.g., mining equipment and construction machinery).

Hard facing can be done with various methods, including welding, thermal spraying, and cladding.

The most common method of hard facing is welding. This is because welding offers many benefits over other methods, such as the ability to deposit a variety of materials, control over the thickness of the deposited layer, and low cost.

Thermal spray methods are also commonly used for hard facing, especially when depositing ceramic materials.

Cladding is another option for hardfacing using hardfacing welding rods, but it generally has a lower deposition rate than either welding or thermal spraying.

What is Hard Facing Welding?

Hardfacing, also known as hardsurfacing, is the application of a wear-resistant material to a base metal. It can provide resistance to abrasion, erosion, or impact.

Hardfacing can extend the service life of a component by depositing a layer of harder material on its surface. This process can be used to repair worn-out or damaged parts, or to strengthen components that are subject to high levels of wear.

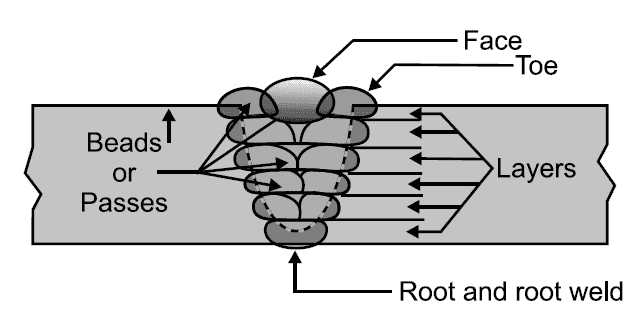

During Hardfacing a special filler metal is applied to the base metal to be hard-faced, and then the two metals are fused together. The filler metal must have a higher hardness than the base metal in order to be effective.

There are many different types of hardfacing materials that can be used, including chromium carbide, tungsten carbide and niobium carbide.

Hard Facing Methods

Hardfacing is a process of depositing a wear-resistant layer on the surface of a metal. This process can be done using various methods, including

- Welding,

- Thermal Spraying, and

- Cladding.

- Welding is the most common method of hard facing, and it can be used to deposit both ferrous and non-ferrous metals. A variety of welding processes can be used, including arc welding, gas tungsten arc welding (GTAW), MIG, Metal Cored, Laser and plasma arc welding (PAW).

- Thermal spraying is another popular method, and it can be used to deposit both metals and ceramics. In thermal spraying, molten material is sprayed onto the surface to be coated. The molten material forms a metallurgical bond with the substrate and cools to form a wear-resistant layer.

- Cladding is a less common method, but it has the advantage of being able to deposit very thick layers.

The best hard facing method for a particular application will depend on the specific needs of the industry or company. Factors such as cost, durability, and ease of use must all be considered before making a decision.

Hard-facing Welding Rod

Hard-facing welding rods can be made from a variety of materials, including carbon steel, chromium, and tungsten.

AWS A5.13 Specification covers hard-facing welding rods or Stick welding or SMAW. All surfacing electrodes for shielded metal arc welding are covered in this specification.

Following are the types of hard-facing welding rods:

- Iron Base Hard facing rods. E.g., EFe-1, EFeMn-A, EFeCr-A2, etc.

- Nickel and Cobalt Base Hard facing rods. E.g., ECoCr-A, ENiCr-C, ENiCrMo-5A, etc.

- Copper Base Hard facing rods. E.g., ECuAl-A2, ECuSi, ECuNiAl, etc.

Hard Facing MIG Wire

Surfacing or hard-facing MIG wire is a welding wire used to build up worn-out or damaged parts. It can also be used to protect new parts from wear and tear.

The AWS A5.21 specification covers MIG and TIG hard-facing wires.

Hard-facing MIG wires and TIG wires are available in two forms:

- Solid Hard facing MIG & TIG Wires,

- Cored (metal cored & flux cored) Hard facing MIG & TIG Wires.

The commonly used Hard Facing MIG wires are:

- Iron Base Hard facing Electrodes/ Filler wires: ERFe-1, ERFe-2, ERFeCr-A, etc.

- Cobalt and Nickel base Bare electrodes for hard facing: ERCoCr-A, ERCoCr-B, ERNICr-A, etc.

- Cobalt and Nickel base Metal cored & Flux cored electrodes: ERCCoCr-A, ERCNiCr-A, ERCNiCrMo-5A, etc.

- Solid and Cored Copper base hard facing electrodes: ERCuAl-A2, ERCuSi-A, ERCuSn-D, etc.

- Tungsten carbides electrodes, WC1, W2C, WC2, etc.