ERCuAl-A2 is a type of welding wire that is commonly used in the welding of aluminum bronze alloys. It is a copper-based alloy that also contains aluminum and iron, with small amounts of nickel and manganese.

The ERCuAl-A2 welding wire is typically used for welding marine components, such as propellers, and other components that are exposed to seawater. It is also used in the welding of copper-nickel alloys and other non-ferrous metals.

ERCuAl-A2 Wire Rod Specification & Classification

ERCuAl-A2 welding wire Rod specification is AWS A5.7. This is a solid bare wire rod available in straight length and wire spool form for TIG Welding and MIG welding applications.

- Classification: ERCuAl-A2

- Specification: AWS A5.7

- ISO Equivalent wire: ISO 24373: Cu6180 CuAl10Fe

ERCuAl-A2 is the classification of this wire rod. In AWS A5.7, chemical and mechanical properties requirements are specified for ERCuAl-A2.

ERCuAl-A2 welding wire Chemical Compositions

The chemical composition of ERCuAl-A2 welding wire as per AWS A5.7 typically includes the following elements:

| Element | Chemical Composition |

| Zn% | 0.02 maximum |

| Si% | 0.10 maximum |

| Fe% | 1.5 maximum |

| Al% | 8.5- 11 maximum |

| Pb% | 0.02 maximum |

| Other elements% | 0.5 maximum |

| Cu% | Reminder |

ERCuAl-A2 welding wire Mechanical Properties

The mechanical properties of welded joints made with ERCuAl-A2 welding rod can vary depending on a number of factors, such as the welding technique used, the thickness and composition of the base material, and the welding conditions.

However, the following are typical mechanical properties for ERCuAl-A2 welding rod:

- Tensile strength: >415 MPa (60 KSi),

- Yield strength: >300 MPa,

- % Elongation: > 35

- Hardness: 130–150 HV

ERCuAl-A2 F number and A Number

ERCuAl-A2 F Number as per ASME Section IX is “36”. The weld wire classification UNS Number is C61800. The A Number for ERCuAl-A2 weld deposit chemistry is not given in ASME Section IX.

Uses of ERCuAl-A2 Wire

The ERCuAl-A2 filler metal, which contains iron-bearing aluminum bronze, is typically employed for welding:

- Aluminum bronzes with similar compositions,

- Manganese bronze,

- Silicon bronze, and

- Certain copper-nickel alloys, ferrous metals, and

- Dissimilar metals.

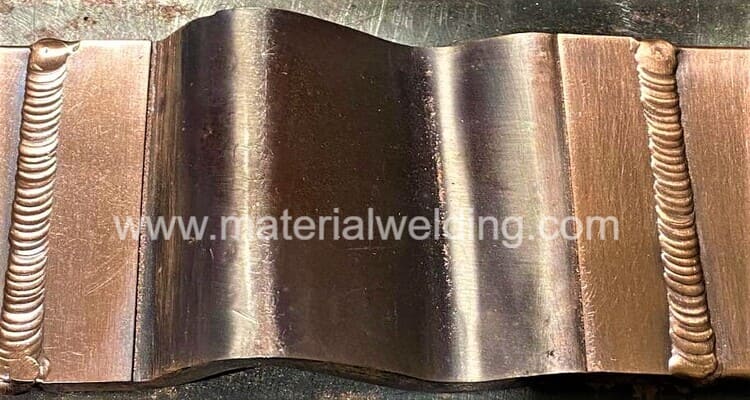

One of the more prevalent combinations of dissimilar metals involves joining aluminum bronze to steel and copper to steel.

This particular alloy is also utilized for its ability to form surfaces that are resistant to both wear and corrosion.

ERCuAl-A2 TIG Rod

ERCuAl-A2 TIG (Tungsten Inert Gas) rod is a type of welding rod used in TIG welding to join aluminum bronze alloys. It is a copper-based alloy that contains aluminum and iron, as well as small amounts of nickel and manganese.

The TIG welding process involves melting the welding rod and the base metal together using a non-consumable tungsten electrode, while a shielding gas (usually argon or helium) is used to protect the molten metal from atmospheric contamination.

ERCuAl-A2 TIG rod is commonly used in applications where high strength and corrosion resistance are required, such as marine components, heat exchangers, and other non-ferrous metal components. It is also used in the repair of aluminum bronze components.

Read more:

ERCuAl-A2 offers excellent corrosion resistance in comparison to stainless steel, making it a great option for welds that will be exposed to harsh environments.

ERCuAl-A2 TIG rod is available in standard 1-meter lengths and in sizes of 0.035, 0.45, 1/16, 3/32 and 1/8 inches.

TIG welding using ERCuAl-A2 tig rod is carried out using 100% argon or a mix of argon 75% + helium 25%.

ERCuAl-A2 MIG wire

ERCuAl-A2 MIG (Metal Inert Gas) wire is a type of welding wire used in MIG welding to join aluminum bronze alloys.

It is a copper-based alloy that contains aluminum and iron, as well as small amounts of nickel and manganese.

The MIG welding process involves feeding the welding wire continuously into the welding pool while a shielding gas (usually argon or a mix of argon and helium) is used to protect the molten metal from atmospheric contamination.

ERCuAl-A2 MIG wire is commonly used in applications where high strength and corrosion resistance are required, such as marine components, heat exchangers, and other non-ferrous metal components. It is also used in the repair of aluminum bronze components.

The wire is manufactured according to the AWS A5.7 specification and is available in wire spool form in sizes of 0.035, 0.45, 1/16, 3/32, and 1/8 inches.