Welding of Monel 400

Welding of Monel 400 is good, however, it can be quite challenging due to the risk of cracking. Stick welding Monel 400 is a good option although requires cleaning and control of moisture in electrode coating.

Monel 400 welding with TIG or MIG require gas purging. Weld without purging will be brittle and prone to cracking. The best way to avoid this issue is to use a right welding rod and follow the right procedure. This article covers Monel 400 welding, Monel 400 to other alloys welding.

What is Monel 400 Material

Monel 400 is a binary alloy of Copper (Cu) + Nickel (Ni) having UNS Number- N04400. It is also called 67Ni–30Cu alloy.

Monel ASME Section IX P Number is ‘42‘ for welding & P No. 110 for Brazing. Monel being a primary Nickel base has austenitic microstructure and hence is a non-hardenable alloy by heat treatment.

The properties such as hardness can only be enhanced by cold working. Monel 400 has high strength at room temperature as well as subzero temperature due to its solid solution structure & high toughness because of Nickel in many corrosion applications where it offers very high corrosion resistance also.

The application of Monel 400 is found in shipbuilding, oil & gas, crude oil refining & marine environment. Monel 400 loses its magnetization at 70-120°F (21-50°C) which is its curie temperature.

Monel 400 Equivalent Material

W. Nr 2.4360, AMS 4730, BS-3072NA13

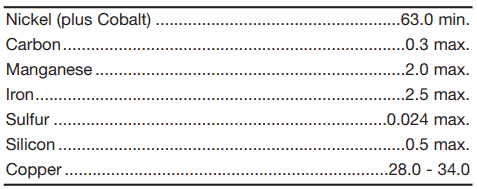

Monel 400 Chemical and Mechanical properties

The density of Monel is 8.8 g/cm3. Monel 400 has a minimum tensile strength of 70 Ksi or 485 N/mm2 and Yield strength in the range of 25-50 ksi (172-345 N/mm2).

The chemical properties of Monel 400 are given in the below table.

Monel 400 Welding Wire

Monel 400 welding wire is used for joining Monel 400 and other nickel-copper alloys, as well as for overlaying steel to protect it from corrosion.

The ERNiCu-7 and ERNi-1 Monel 400 welding wires are used for gas metal arc welding (GMAW). They are used with pure argon as shielding gas.

Welding Monel 400 to Carbon Steel

Stick or SMAW Welding of Monel 400 to Carbon steel or mild steel shall be carried out with ENiCu-7 (AWS SFA No. 5.11) or with ENi-1 (AWS SFA No. 5.11).

👉👉 Check out this ENiCu-7 Welding Rod 👉👉

The dissimilar welding of Monel 400 to carbon steel is readily weldable.

No special baking or conditioning of welding electrodes is required. TIG or MIG welding of Monel 400 to carbon steel is welded using ERNiCu-7 or ERNi-1 (AWS SFA 5.15).

ENi-1 is a nickel-base electrode having 95% Ni and 2.5% Titanium and is mainly used for welding pure nickel and welding carbon steel to nickel alloys.

Read more:

The composition of ENiCu-7 is 66% Nickel, 30% Copper, 3% Mn, and 1% Iron (Fe) so basically similar to metallurgy to Monel 400 alloy.

Welding Monel 400 to Stainless Steel

Stick or SMAW Welding of Monel 400 to stainless steel SS304 or any other 300 series stainless steel is welded using ENi-1 or ENiCrFe-2 or -3 (As per AWS SFA/A 5.11).

Welding of Monel 400 to SS410, 430, or other 400 series stainless steel is carried out using ENiCu-7 electrode (AWS SFA/A 5.11).

TIG or MIG Welding of Monel 400 to Monel to stainless steel SS304 or any other 300 series stainless steel is welded using ERNi-1 or ERNiCrFe-6 or ERNiCr-3 (As per AWS SFA/A 5.14).

The TIG welding electrode equivalent of ENiCrFe-3 is ERNiCr-3 & equivalent of ENiCrFe-2 is ERNiCrFe-6.

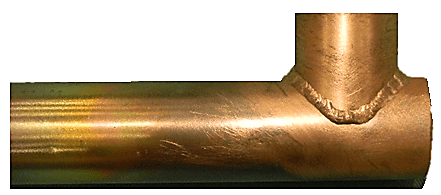

Welding Monel 400 to 90-10 Cu-Ni & 70-30 Cu-Ni

Stick or SMAW Welding of Monel 400 to Cupronickel such as 90-10 Cu-Ni & 70-30 Cu-Ni is carried out using ENiCu-7 (AWS SFA No. 5.11).

Welding Monel 400 to Hastelloy

Welding of Monel 400 to Hastelloy is not advised as the presence of copper in Hastelloy will increase the chances of hot cracking.

If still welding of Monel 400 to Hastelloy C22 or C276 is required, use ENi-1 or ERNi-1 welding electrode/ filler wire.

Welding Procedure for Monel 400

- Clean the parts to be joined.

- Weld using ENiCu-7 or ERNiCu-7 electrode/ Filler wire.

- Keep the heat input on the lower side.

- Avoid the arc strikes on the base materials.

- Take precautions by using the right welding condition and good quality shielding gases to avoid any porosity issues.

Stick/ SMAW Welding of Monel 400

Stick or SMAW Welding of Monel 400 to Monel 400 is carried out using ENiCu-7 (AWS SFA No. 5.11). ENiCu-7 is also known as Monel welding electrode 190 (Brand name of Special Metals).

ENiCu-7 provides a weld deposit of similar metallurgy and gives welding without any difficulties.

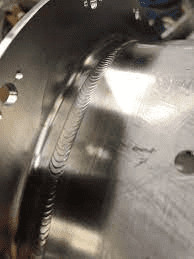

Tig & MIG Welding of Monel 400

Gas Tungsten arc welding (GTAW)/ TIG or Metal Inert Gas or MIG Welding of Monel 400 to Monel 400 shall be carried out with ERNiCu-7 (AWS SFA No. 5.15).

The composition of ENiCu-7 is 66% Nickel, 30% Copper, 3% Mn, and 1% Iron (Fe) so basically similar to the metallurgy of Monel 400 alloy.

Pure argon is used for shielding and gas backing/ purging work. The weld deposit is clean and should be deposited with lower heat input to avoid any distortion issues.

Preheat, Interpass & PWHT of Monel 400

Being a Face Centered Cubic Microstructure having an austenitic phase, Monel 400 does not require any preheating.

Interpass temperature for Monel 400 welding shall be kept to a maximum of 300 °F (150 °C). throughout the welding operation. Post weld heat treatment (PWHT) is not required for Monel 400.

Welding Electrode for Monel 400

Stick welding or shielded metal arc welding (SMAW) of Monel 400 is carried out using an ENiCu-7 rod.

No special conditioning is required for the stick welding rods. Clean slag properly after each run to avoid any issue of slag entrapment which could otherwise reduce the material corrosion resistance. ENiCu-7 has good weldability.

Monel 400 vs Inconel 625

Monel 400 to Inconel 625 is also a combination not used in industries as both are alloys of different purposes.

If you still need to join Monel 400 to Inconel 625, use ERNiCrFe-6 or ERNiCr-3 (As per AWS SFA/A 5.14). Use pure argon for shielding and purging.

Hastelloy vs Monel

When it comes to corrosion-resistant alloys, Hastelloy and Monel are two of the most popular options. But which one is right for you?

Read more: Hastealloy C276 Material Properties & applications.

Here’s a closer look at the key differences between Hastelloy and Monel:

Both Hastelloy and Monel are corrosion-resistant alloys that are used in a variety of industries. However, there are some key differences between the two alloys.

Hastelloy is more resistant to chloride-induced stress corrosion cracking than Monel. Additionally, Hastelloy has better resistance to pitting and crevice corrosion than Monel. Hastelloy is also more expensive than Monel.

Hastelloy is a nickel-based alloy that offers excellent resistance to a wide range of corrosive materials, including acids, alkalis, and salt water.

It also has good mechanical properties and can be used at high temperatures. Hastelloy is commonly used in chemical processing, oil and gas production, and petrochemical applications.

Monel is a nickel-copper alloy that offers excellent resistance to corrosion by many different types of chemicals.

It has good mechanical properties and can be used at high temperatures. Monel is commonly used in marine applications, food processing, and chemical processing.