ERNiCu-7 Welding Wire

ERNiCu-7 welding rod is a Cu-Ni (Copper-nickel) solid wire rod for TIG and MIG welding Monel 400, 405 & K500 (NO4400, NO4405 & NO5500).

It is also used for welding 2.4360 NiCu30Fe and 2.4375 NiCu30Al alloy.

ERNiCu-7 is also used for welding Nickel 200 to Cu-Ni alloys as well as weld cladding applications on carbon steel material.

ERNiCu-7 welding wire Specification & Classification

ERNiCu-7 welding wire specification is AWS A5.14. This is a solid bare wire rod available in straight length and wire spool form for TIG and MIG welding applications.

- Classification: ERCuNi-7

- Specification: AWS A5.14

- ISO Equivalent wire: ISO 18274: S NI 4060 (NiCu30MnTi)

ERNiCu-7 is the classification of this wire rod. In AWS A5.14, chemical and mechanical properties requirements are specified for ERNiCu-7.

ERNiCu-7 welding wire Chemical Compositions

ERNiCu-7 welding wire is a versatile alloy composed of copper and nickel. ERNiCu-7, also known as CuNi welding wire, provides excellent strength and outstanding corrosion resistance in many applications.

This combination of properties makes it an ideal choice for a variety of different tasks in the automotive, marine, petrochemical and aerospace industries.

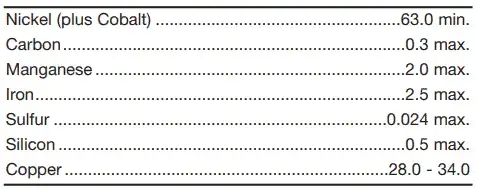

Chemical compositions as per AWS A5.14 for ERNiCu-7 welding wire are:

| Element | Chemical Composition |

| C% | 0.15 maximum |

| Mn% | 4.0 maximum |

| Fe% | 2.5 maximum |

| P% | 0.02 maximum |

| S% | 0.015 maximum |

| Si% | 1.25 maximum |

| Cu% | Reminder |

| Ni% | 62.0 – 69.0 |

| Al% | 1.25 maximum |

| Ti% | 1.5 – 3.0 |

| Other elements | 0.50 maximum |

ERNiCu-7 welding wire Mechanical Properties

Mechanical properties requirements are not specified for ERNiCu-7 welding wire in AWS A5.14 specification.

As per AWS A5.14, only a chemical analysis test for filler wire is required. However, typical mechanical properties of ERCuNi-7 welding wire are:

- Tensile strength: >500 MPa,

- Yield strength: >300 MPa,

- % Elongation: > 35

ERNiCu-7 F number and A Number

ERNiCu-7 F Number as per ASME Section IX is “42”. The weld wire classification UNS Number is N04060. The A Number for ERNiCu-7 weld deposit chemistry is not classified in ASME Section IX.

ERNiCu-7 TIG Rod

ERNiCu-7 TIG rod is an ideal choice for welding Monel 400, 405 and K500 alloys. This copper-nickel base alloy is one of the most versatile and widely used TIG rods in the industry.

Read more:

ERNiCu-7 offers excellent corrosion resistance in comparison to stainless steel, making it a great option for welds that will be exposed to harsh environments.

ERNiCu-7 TIG rod is available in standard 1-meter lengths and in sizes of 0.035, 0.45, 1/16, 3/32 and 1/8 inches.

TIG welding using ERNiCu-7 tig rod is carried out using 100% argon or a mix of argon 75% + helium 25%.

ERNiCu-7 MIG wire

ERNiCu-7 is a copper-nickel alloy wire that offers superior corrosion resistance and strength when used in welding applications.

This specialized MIG wire is designed to deliver excellent weld quality and ease of use, even with thin sheet sections or complex joint designs.

The wire is manufactured according to the AWS A5.14 specification and is available in wire spool form in sizes of 0.035, 0.45, 1/16, 3/32, and 1/8 inches.