Hastelloy C276 Alloy

Hastelloy C-276 is a nickel-chromium-molybdenum alloy that is highly resistant to corrosion in a wide range of aggressive environments.

It is particularly effective in applications involving strong oxidizing acids, such as ferric and cupric chlorides, as well as hot contaminated media, including organic and inorganic compounds.

It also offers resistance to stress corrosion cracking and pitting. Due to its excellent corrosion resistance, Hastelloy C-276 is commonly used in the chemical processing, petrochemicals, pollution control, and nuclear industries.

Hastelloy C276 Material Specification & Standard

Hastelloy C276 ASTM Standard/ specification is ASTM B575. The UNS Number of Hastelloy C276 Alloy is UNS N10276.

Some of the common standards and specifications for Hastelloy C-276 include:

- ASTM B575: Standard Specification for Nickel-Chromium-Molybdenum-Iron Alloys (UNS N10276 and UNS N06022) Plate, Sheet, and Strip.

- ASTM B622: Standard Specification for Seamless Nickel and Nickel-Cobalt Alloy Pipe and Tube.

- ASTM B626: Standard Specification for Welded Nickel and Nickel-Cobalt Alloy Pipe.

- AMS 5513: Steel, Corrosion and Heat-Resistant, Sheet, Strip, and Plate, 18Cr – 14Ni – Mo – W (UNS N10276).

- ASME SB-564: Nickel Alloy Forgings.

- DIN 2.4819

- ASTM B366: Fittings

- ASTM B462: Forgings

- ASTM B619: Welded Pipes.

Hastelloy c276 Equivalent Material

Hastelloy c276 UNS Number is UNS N10276. Hastelloy c276 ASME P Number is 43. Hastelloy c276 DIN equivalent is DIN 2.4819. Hastelloy c276 EN Number is 2.4819.

There are other alloy materials that have similar corrosion resistant properties and can be considered as equivalent to Hastelloy C-276. Some of these include:

- Alloy C-2000: A nickel-chromium-molybdenum-copper alloy that offers similar corrosion resistance to Hastelloy C-276, but with improved resistance to crevice and pitting corrosion.

- Alloy 20: A nickel-chromium-molybdenum-copper alloy that offers good resistance to pitting and crevice corrosion in a range of environments, including sulfuric acid and phosphoric acid.

- AL-6XN: An alloy of nickel, chromium, and molybdenum that offers excellent resistance to chloride-induced pitting and crevice corrosion.

- Inconel 625: A nickel-chromium-molybdenum alloy that offers good resistance to pitting and crevice corrosion, as well as excellent strength and toughness at high temperatures.

- Incoloy 825: A nickel-iron-chromium alloy that offers good resistance to pitting and crevice corrosion, as well as excellent resistance to stress corrosion cracking and erosion corrosion.

Hastelloy c276 alloy low temperature limits is to be specified by the engineer and high temperature limit is 870 – 1230°C (1600 – 2250°F).

Hastelloy c276 Chemical Compositions

The typical chemical composition of Hastelloy C-276, in weight percentage, is:

- Nickel: Balance,

- Chromium: 14.5-16.5,

- Molybdenum: 15-17,

- Iron: 4-7,

- Tungsten: 3-4.5,

- Cobalt: 2.5 max,

- Manganese: 1 max,

- Silicon: 0.08 max,

- Carbon: 0.01 max,

- Sulfur: 0.03 max,

- Phosphorus: 0.04 max.

Hastelloy C276 Mechanical Properties

Hastelloy C276 alloy is known for its excellent corrosion resistance properties and also has good mechanical properties.

The mechanical properties of Hastelloy C-276 vary depending on the specific condition of the alloy (such as annealed, aged, or cold-worked).

Some typical mechanical properties for Hastelloy C-276 in the annealed condition (at room temperature) include:

- Tensile strength: 100 Ksi, (690 MPa),

- Yield strength: 41 Ksi, (283 MPa)

- Elongation: 40% minimum

- Hardness (Rockwell B): 100 max.

- Density: 8.89 g/cm3 (0.321 lbs/in3)

- Modulus of Elasticity: 28.3 x 106 psi, 195 GPa

Hastelloy c276 Applications

Hastelloy C-276 is a highly corrosion-resistant alloy that is well-suited for a wide range of industrial applications. Some of the most common applications of Hastelloy C-276 include:

- Chemical processing: Hastelloy C276 Alloy is used in the chemical processing industry for equipment and piping that come into contact with highly aggressive chemicals, such as strong acids and bases.

- Pollution control: Hastelloy C276 Alloy is used in pollution control equipment, including scrubbers, ducts, and stacks, to resist corrosion from acidic and contaminated gases.

- Nuclear industry: Hastelloy C276 Alloy is used in the nuclear industry for various components of nuclear power plants, such as fuel cladding, control rod components, and various other reactor coolant systems components.

- Pharmaceuticals: Hastelloy C276 Alloy is used in the pharmaceutical industry for equipment and piping that come into contact with corrosive chemicals and high-purity fluids.

- Marine and offshore: The alloy is used in marine and offshore environments for various components, such as piping, valves, and pumps, due to its excellent resistance to corrosion from seawater and salt spray.

- Pulp and paper: Hastelloy C276 Alloy is used in the pulp and paper industry for equipment and piping that come into contact with corrosive chemicals, such as bleaches, acids, and caustic solutions.

- Aerospace: Hastelloy C276 Alloy is used in aerospace industry for various components, such as engine exhaust systems, due to its excellent high-temperature strength and corrosion resistance properties.

Hastelloy c276 Heat Treatment

The heat treatment process for Hastelloy C276 Alloy typically involves heating the alloy to a specific temperature, holding it at that temperature for a certain period of time, and then cooling it at a specific rate.

Solution annealing is the common heat treatment method for Hastelloy C-276. This process is done by heating the alloy to a temperature between 1950°F and 2150°F (1065°C and 1175°C) for a few minutes and then rapidly cooled by quenching it in water or air.

This process is done to dissolve any carbides and other intermetallic compounds that may be present in the alloy and to provide a homogenous microstructure.

Aging treatment is another heat treatment that can be used for Hastelloy C-276. This process is done by heating the alloy to a temperature between 1200°F and 1300°F (650°C and 700°C) for a period of time between 8 and 16 hours and then cooled to room temperature. This process is done to improve the strength, particularly the yield strength of the alloy.

Hastelloy c276 Welding

Hastelloy C276 Alloy is a nickel-chromium-molybdenum alloy that can be welded using various welding techniques.

However, due to its high nickel content and high molybdenum content, it can be prone to cracking. Therefore, proper welding procedures and techniques must be used to minimize these issues.

Read more: Hastelloy C276 Welding Guide.

Gas tungsten arc welding (GTAW) and gas metal arc welding (GMAW) are the most common welding methods used for Hastelloy C276 Alloy.

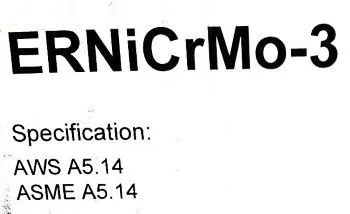

It’s essential to use an appropriate filler wire such as ERNiCrMo-4 that is compatible with the base material, such as Hastelloy C276 Alloy.

The filler wire should be of the same composition as the base material or slightly higher in nickel and molybdenum content.

hastelloy c276 compatibility chart

A compatibility chart is a useful tool that shows the compatibility of a particular material, such as Hastelloy C-276, with other materials and substances. The chart typically lists the materials and substances that are compatible with the alloy, as well as those that are not compatible.

Hastelloy C-276 is a highly corrosion-resistant alloy that is compatible with a wide range of chemicals, including:

- Organic acids (such as acetic, formic, and oxalic acid)

- Inorganic acids (such as sulfuric, hydrochloric, and phosphoric acid)

- Chlorides (such as sodium chloride and hydrochloric acid)

- Alkalis (such as sodium hydroxide and potassium hydroxide)

However, Hastelloy C-276 is not compatible with certain materials and substances, such as:

- Strong reducing agents (such as aluminum and zinc)

- Wet chlorine gas

- Hot concentrated sulfuric acid

It’s important to note that the chemical compatibility of a material can be affected by various factors such as temperature, concentration, pressure, and the presence of other chemicals

Hastelloy c22 vs c276

the key differences between Hastelloy C-22 and C-276:

| Property | Hastelloy C-22 | Hastelloy C-276 |

| Chemical Composition | Ni: Balance, Cr: 22, Mo: 13, W: 3.5-4.5, Fe: 2.5 max, Co: 2 max, Mn: 1 max, Si: 0.08 max, P: 0.03 max, S: 0.02 max | Ni: Balance, Cr: 14.5-16.5, Mo: 15-17, W: 3-4.5, Fe: 4-7, Co: 2.5 max, Mn: 1 max, Si: 0.08 max, P: 0.04 max, S: 0.03 max |

| Corrosion Resistance | Excellent resistance to pitting, crevice corrosion and stress corrosion cracking. Good resistance to oxidizing and non-oxidizing acids. Superior resistance to chloride-induced pitting and crevice corrosion than C-276 | Excellent resistance to corrosion in a wide range of aggressive environments. Good resistance to stress corrosion cracking and pitting. |

| Applications | Chemical processing, pharmaceutical, pollution control | Chemical processing, pollution control, nuclear |

| Mechanical Properties | Tensile strength: Psi – 110,000, MPa – 758, Yield strength: Psi – 52,000, MPa – 358, Elongation: 45%, Hardness (Rockwell B): 90 max, Density: 0.321 lbs/in3, 8.89 g/cm3, Modulus of Elasticity: 28.3 x 106 psi, 195 GPa, Poisson’s Ratio: 0.29 | Tensile strength: Psi – 110,000, MPa – 758, Yield strength: Psi – 52,000, MPa – 358, Elongation: 45%, Hardness (Rockwell B): 90 max, Density: 0.321 lbs/in3, 8.89 g/cm3, Modulus of Elasticity: 28.3 x 106 psi, 195 GPa, Poisson’s Ratio: 0.29 |

| Heat Treatment | Solution Annealing: 1850-2150°F (1010-1175°C) / Rapid cooled by quenching in water or air. Ageing treatment: 1200-1300°F (650-700°C) / 8-16 hours / cooled to room temperature | Solution Annealing: 1950-2150°F (1065-1175°C) / Rapid cooled by quenching in water or air. Ageing treatment: 1200-1300°F (650-700°C) / 8-16 hours / cooled to room temperature |

| Welding | GTAW and GMAW with an appropriate filler wire. Low heat input and low interpass temperature. Post-weld heat treatment recommended | GTAW and GMAW with an appropriate filler wire. Low heat input and low interpass temperature. Post-weld heat treatment recommended |

| Standards & Specifications | ASTM B574, ASTM B575, ASTM B622, ASTM B626, AMS 5599, AMS 5666, AMS 5750, NACE MR0175/ISO 15156-3, ISO 15156-3, DIN 2.4602 | ASTM B575, ASTM B622, ASTM B626, AMS 5513, ASME SB-564, NACE MR0175/ISO 15156-3, ISO 15156-3, DIN 2.4819 |

FAQS

Hastelloy c276 PREN Number

Is Hastelloy c276 stainless steel?

Hastelloy C-276, on the other hand, is a Nickel-based alloy containing nickel-chromium-molybdenum. While it does contain chromium, it also contains a high amount of nickel, molybdenum, and other elements which makes it different from stainless steel.

Is Hastelloy c276 Magnetic?

Is Hastelloy c276 NACE Compliant?

Hastelloy C-276 is commonly used in the oil and gas industry, particularly in sour service applications, due to its excellent resistance to corrosion in a wide range of aggressive environments.