What is alloy 20 Cb3

Alloy 20Cb3, UNS No. N08020 is an alloy of Ni-Fe-Cr. The primary microstructure is predominately austenite for Alloy 20.

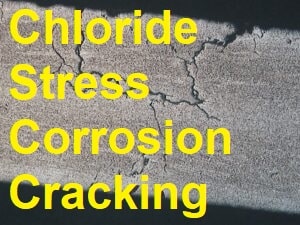

Niobium (Nb) is added to alloy 20 for stabilization and to prevent intergranular corrosion or IGC. Alloy 20 offers high corrosion resistance (in various aggressive media- such as sulfuric acid and many other chemicals) in various environment such as pitting corrosion, crevice corrosion, and general corrosion application.

This material is widely used in oil & gas such as refineries, chemical plants, food processing, and piping. The usual upper operating temperature limit of alloy 20Cb3 is 1000°F.

Material Specification

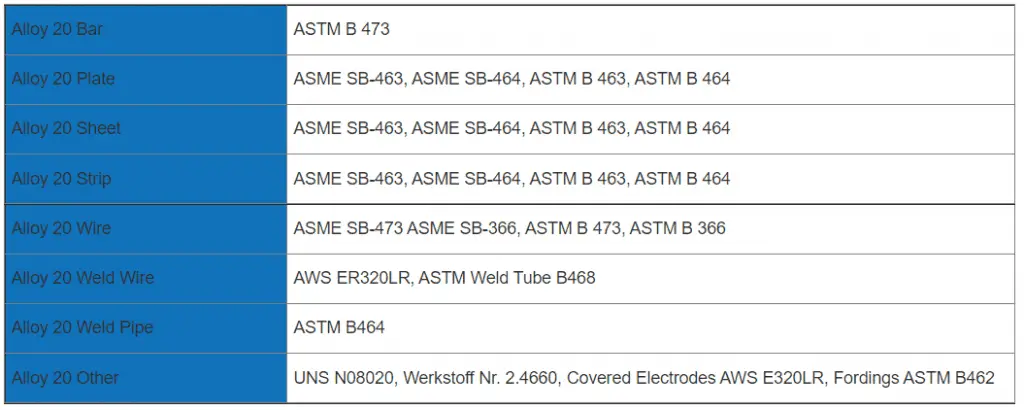

The UNS Number of Alloy 20CB3 is UNS N08020, W. Nr 2.4660. ASME Section IX P Number for welding for Alloy 20CB3 is P. No. 45.

The material specification for alloy 20CB3 is ASTM B473, B464, B464, B468. A detailed materials specification for these alloys is given in the below table.

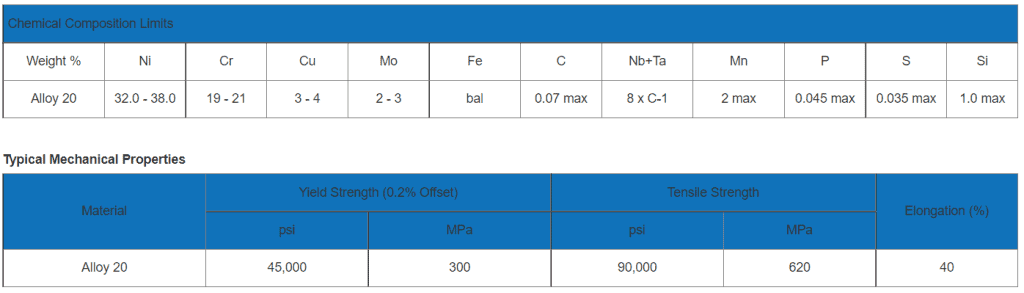

Chemical composition & mechanical properties of of Alloy 20 cb3

The chemical properties and mechanical properties of Alloy 20CB3 are given in the below table.

The tensile strength of alloy 20 is 90Ksi (620 MPa), yield strength is 45Ksi (300 MPa) and elongation is a minimum of 40%.

Alloy 20Cb3 contains nickel from 32 to 38% as a major alloying element, Chromium from 19-21%, copper 3 to 4%, and Mo 2 to 3%. the melting point of alloy 20CB3 is 1425°C (2600°F).

SMAW Welding rod & TIG/MIG filler wire Alloy 20 Welding

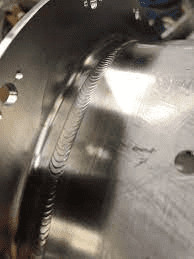

Alloy 20 cb3 is commonly welded by TIG, MIG, and stick-shielded metal arc welding (SMAW). The TIG/MIG welding alloy 20 is carried out using ER320LR filler wire as per electrode specification SFA 5.9.

Stick welding or SMAW welding is carried out using an E320LR rod supplied as per SFA 5.4 electrode specification.

Dissimilar welding using stick welding or SMAW of alloy 20 cb3 to SS316L or Hastelloy C276 is carried out using ENiCrMo-3 (Inconel 625) filler wire as per SFA 5.11.

TIG-MIG welding alloy 20 cb3 to SS316L or Hastelloy C276 is carried out using ERNiCrMo-3. Pure argon is used for shielding when welding using TIG & MIG welding.

Stick welding rod does not require any baking prior to welding using an E320LR rod but it is advised to keep the rods in holding ovens to avoid welding porosity issues.

Properties of ER320LR TIG wire

ER320LR ( where LR means Low Residuals) is a matching TIG/ MIG filler wire for the welding of Alloy 20 cb3.

This classification has the same basic composition as ER320; although C, Si, P, and S are added at lower maximum levels and the Nb and Mn are controlled at minimum levels.

This help to minimize the weld metal hot cracking and fissuring faced in fully austenitic stainless steel welds.

TIG fillers having ferrite can be used in TIG/ MIG welding processes without any noticeable cracking issues.

ER320LR can also be used with the SAW process but there changes for cracking are more when used for joining applications although weld overlay applications are usually crack-free. The tensile strength of ER320LR is lower than ER320 type filler wire.

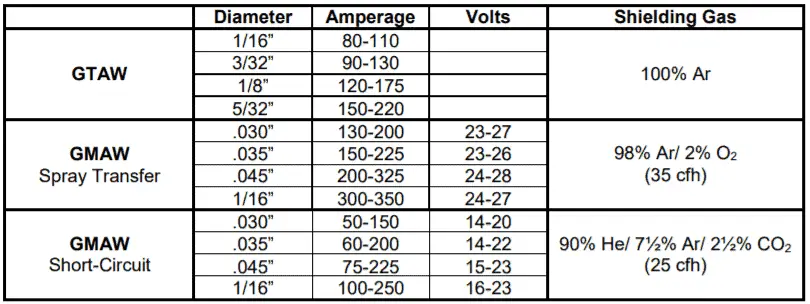

Welding amperage for SMAW & TIG welding of Alloy 20 cb3

In Stick welding or SMAW welding of Alloy 20 cb3, the welding current selection is dependent on electrode diameter & welding position used for welding applications.

Generally, the 1/8” electrode diameter requires a 70 to 90-ampere current. For TIG welding, a current of 100- 140 ampere suits well for different TIG wire diameters.

Typical welding parameters for stick welding, TIG, and MIG welding using ER320LR are given in the below table for reference.

Heat treatment of Alloy 20 cb3

Being an austenitic microstructureAlloy 20Cb-3 is not responsive to heat treatment to increase the hardness.

Annealing of alloy 20CB3 is done at 1725-1850ºF (940- 1010ºC) for 30 minutes per inch of material thickness followed by water quenching.

The purpose of this treatment is to give stabilization to the material for maximum corrosion resistance. Stress relieving is usually not required.

but if there are any design requirements for stress relieving, then it can be carried out at 1000ºF (540ºC).