What is Hastelloy C22?

Hastelloy C22 (Alloy C22) is an austenitic Ni-Cr-Mo-W (nickel-chromium-molybdenum-tungsten) alloy that has high corrosion resistance to various corrosion mechanisms such as crevice corrosion, pitting corrosion, and stress corrosion cracking (SSC).

In this alloy system, Moly & tungsten offer high corrosion resistance for reducing media while Chrome gives resistance to oxidizing media. C22 is widely used in oil & gas as a weld overlay material where high corrosion resistance is required.

Material Specifications

ASTM B 622, B619, B622, B626, B575, B574, B564, B366

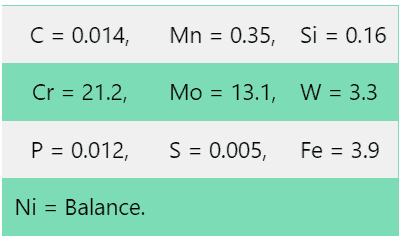

Chemical composition of Hastelloy C22

Below table list the main chemical composition of Hastelloy C22. This is primarily alloyed with Cr, Ni & Mo.

| Carbon | Chrome | Cobalt | Iron | Mn | Moly | Nickel | P | Silicon | S | Tungsten | Vanadium |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0,01 | 20- 22.5 | 2,5 | 2-6 | 0,50 | 12,5-14,5 | Remaining | 0,02 | 0,08 | 0,02 | 2,5-3,5 | 0,35 |

Mechanical properties of Hastelloy C22

The typical mechanical properties of Hastelloy C22 at room temperature are given in the below table.

| Material type | Tensile strength (PSI) | Yield strength (PSi) | Elongation | Hardness (HRB) |

|---|---|---|---|---|

| Plate (0,25”-1,75”) | 112000 | 53000 | 62 | 89 |

| Sheet (0,038”-0,15”) | 122000 | 63000 | 54 | 93 |

| Bar (0,50”-5,50”) | 115000 | 55000 | 60 | 89 |

SMAW, GTAW & GMAW Welding of Hastelloy C22

Nickel-based alloys such as C22 generally exhibit sluggish welding and shallow penetration characteristics; therefore, the possibility of incomplete fusion increases.

Take necessary preventive care to have a good quality weld. If orbital or automatic welding equipment is used, use a pulsed current welding program.

Welding with pulse TIG is one way to have a good fusion with low welding heat input for a controlled dilution rate. Pulse welding offers low heat input, good quality welds, and minimal distortion in welding.

SMAW welding electrode for Hastelloy C22

SMAW welding of Hastelloy C22 shall be carried out using SMAW electrode ENiCrMo-10 (AWS SFA 5.11). ENiCrMo-10 Can join stainless and nickel alloys or dissimilar corrosion-resistant alloys and cladding.

It is suitable for most applications in the as-welded condition for use on Hastelloy C22. ENiCrMo-10 shall also be used to join Hastelloy C22 to carbon steel.

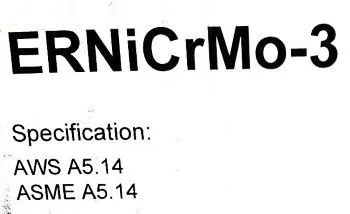

GTAW/TIG welding consumable for Hastelloy C22

GTAW/TIG welding of Hastelloy C22 shall be welded using ERNiCrMo-10 type filler wire. ERNiCrMo-10 filler metal is used for the MIG-MAG (GMAW) and TIG welding of HASTELLOY C-22 material.

Weld deposit made using ERNiCrMo-10 has very good oxidization resistance up to a temperature of 1500°F (815°C). Also, it offers low thermal expansion and excellent fabricability.

Backing gas (100% argon) should always be used for the root pass when welding by either GTAW or GMAW. For SMAW, grinding of the backside of the root pass is necessary.

The typical weld deposit chemistry of ERNiCrMo-10 is given in the below table.

Typical mechanical properties usually achieved using ERNiCrMo-10 are given in the below table for general reference.

These values however can change based on welding heat input and other welding variables that might affect the mechanical properties of the deposited weld.

| Tensile Strength | 113,000 psi |

| Yield Strength | 78,000 psi |

| Elongation | 35.5% |

Preheat & Interpass temperature

No preheating is required for Hastelloy C22 during welding as this is primarily an austenitic base alloy. controlling interpass temperatures, generally, 200°F (93°C) or less is recommended to control the phase balance.

Post weld heat treatments are also not required for this alloy.

Recommended welding parameters for TIG welding

The below table gives the recommended welding parameters for TIG welding of Hastelloy C22.

| Wire Dia. | Voltage (V) | Flat (Current in Amp) | Vertical and Overhead (Current in Amp) |

| 3/32” (2.4 mm) | 22 – 26 | 65 – 80 | 55 – 80 |

| 1/8” (3.2 mm) | 22 – 25 | 80 – 120 | 60 – 100 |

| 5/32” (4.0 mm) | 22– 30 | 100 – 150 | 80 – 125 |

| 3/16”(4.8 mm) | 24 – 31 | 110 – 160 | 100 – 135 |

Welding of Hastelloy C22 to carbon steel & Stainless steel

Welding of Hastelloy C22 to carbon steel and stainless steel such as SS316 shall be carried out using ENiCrMo-10 with SMAW or with ERNiCrMo-10 with TIG or MIG Welding.

Pure argon shall be used for shielding and purging applications with TIG/ MIG welding. When welding with SMAW, the root shall be cleaned properly to remove any remaining slag/ oxides which otherwise can hamper the corrosion resistance of the weld metal.