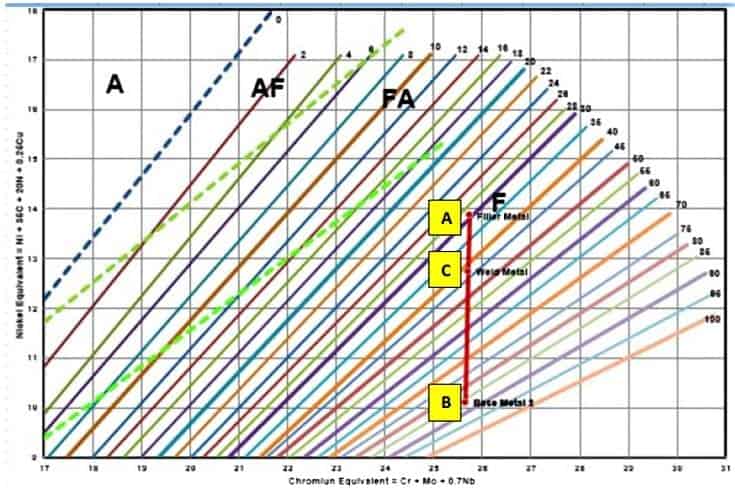

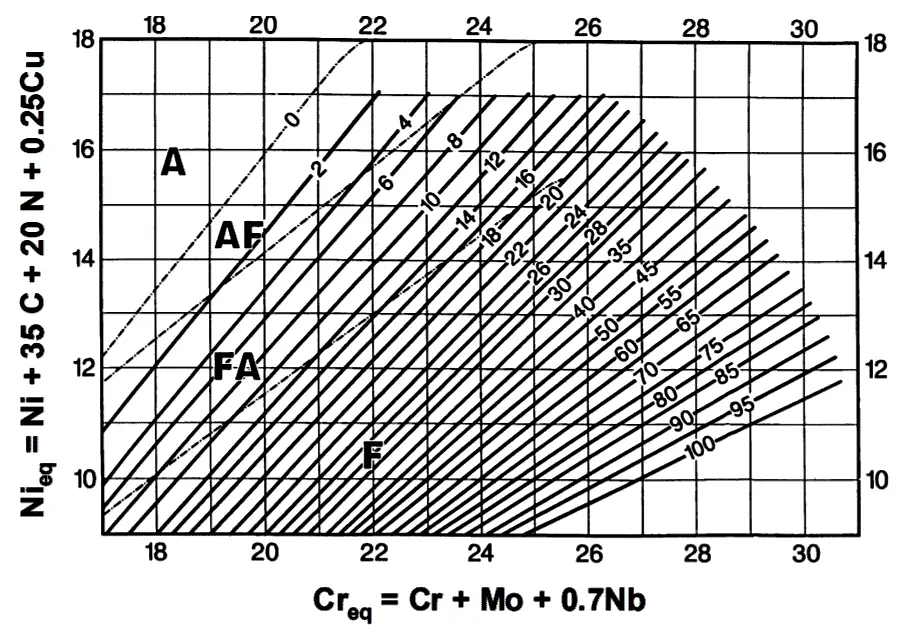

WRC-1992 Constitute Diagram and its Uses

WRC-1992 diagram solves many of the problems faced by the Schaeffler and DeLong diagrams. WRC Diagram was developed with data measured by the most recent definition of the Ferrite Numbers (FN) scale, it removed the erroneous Mn coefficient from the Ni eq and eliminated the systematic overestimation of FN for highly alloyed weld metals.

On one side, the WRC-1992 diagram has a wider range of compositions compared to the DeLong diagram, but the range is narrow compared to the Schaeffler diagram because it extends only over the composition range of the available materials.

Independent data from over 200 weld metals have confirmed the improved prediction accuracy of the WRC-1988 diagram over that of its predecessors and adopted by the ASME therefore in BPVC codes.

WRC-1992 Diagram does not depend on the Manganese (Mn) and Silicon (Si) content as these alloying elements do not produce any significant influence on microstructure during research by the WRC committee on Welding Stainless Steel.

The main application of the WRC-1992 diagram is for stainless steel of 300 series and duplex stainless steel.

The role of predicting free ferrite has been assumed by the WRC-1992 diagram which is more appropriate to the solidification stage.

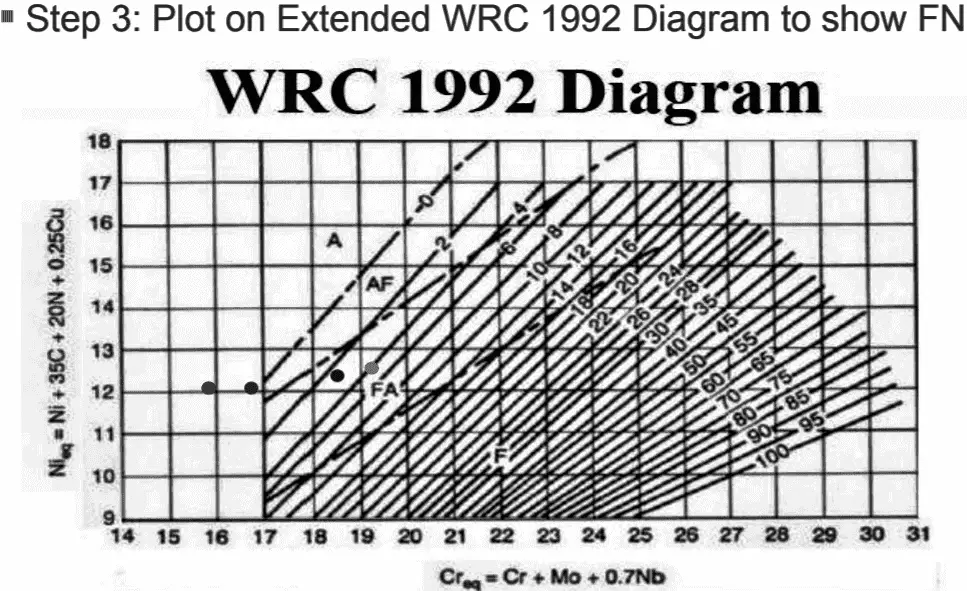

| The Schaeffler diagram does not accurately display the ‘real’ situation since it deals only with the room temperature result. The solidification pattern is considerably different. There have been a series of modifications to the Schaeffler diagram to allow for this with the WRC 1992 diagram as shown in the above figure. |

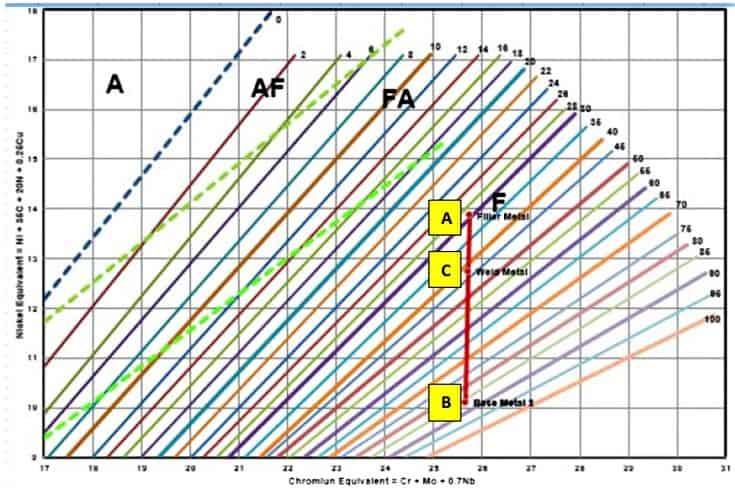

This diagram does not include manganese as an alloying addition and as such is unable to predict the possibility of martensite formation.

Manganese has little effect on the high-temperature formation of ferrite or its transformation to austenite and therefore is of little significance in the fundamental use of the WRC diagram, i.e. the prediction of room temperature ferrite.

Manganese does, however, have an effect on the lower temperature transformation of austenite to martensite and thus the inclusion of this element in the diagram can allow the prediction of martensite regions.

It is for this reason that the original Schaeffler diagram still finds application in dissimilar weld structure prediction. One particular area of the usefulness of the Schaeffler diagram is to indicate the type of behavior that can be expected with welds of various compositions.

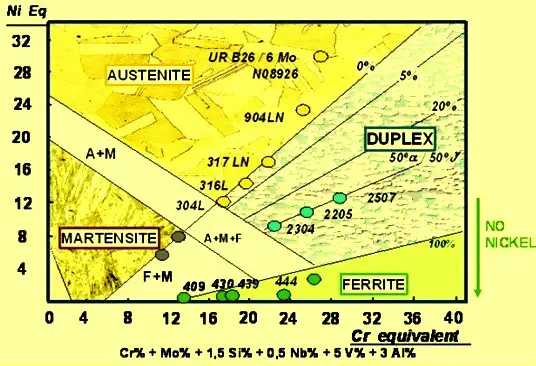

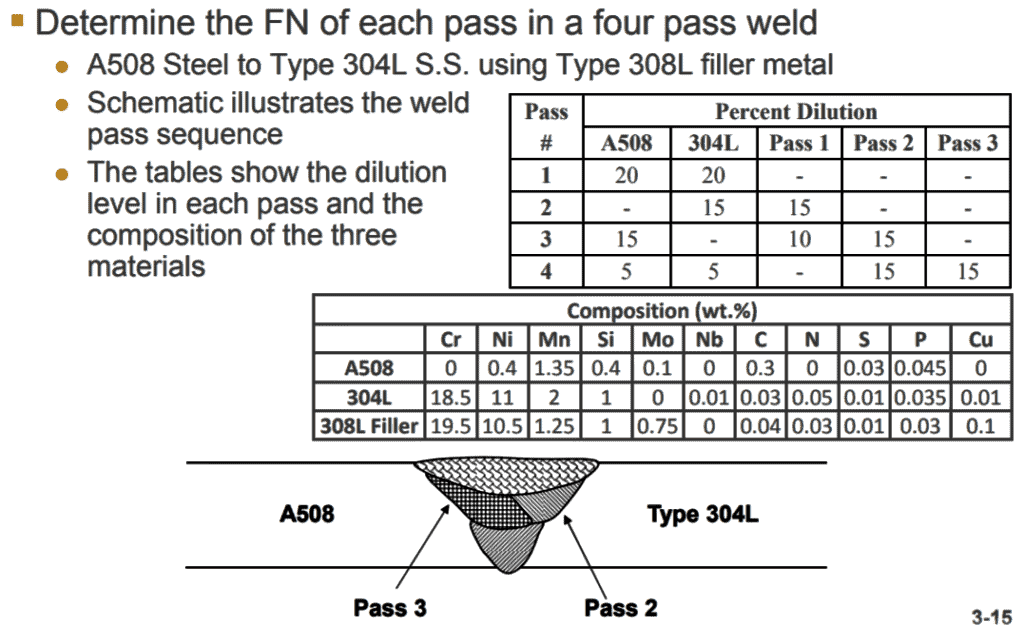

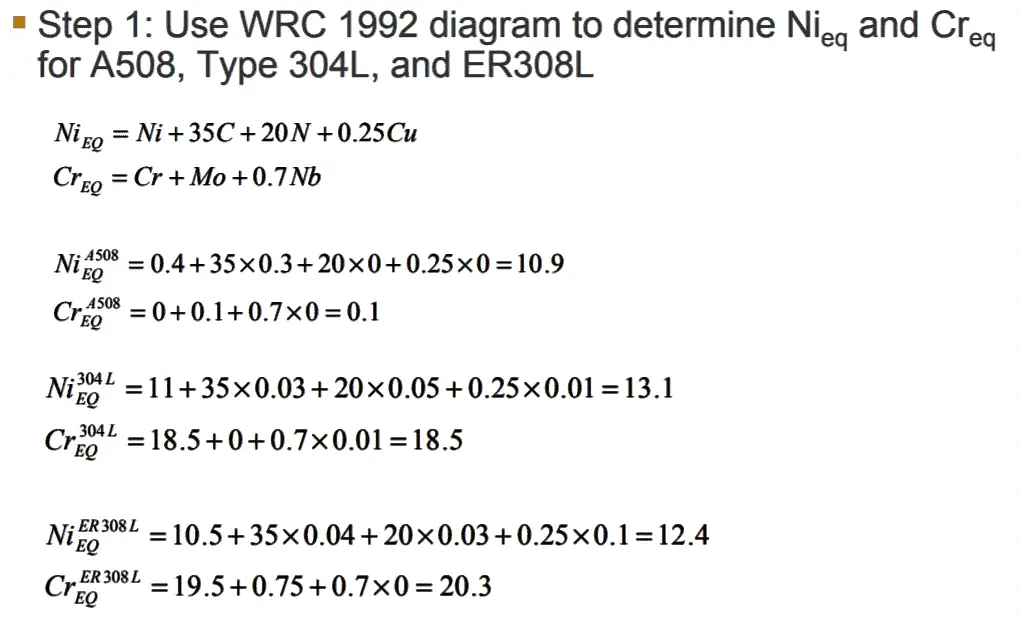

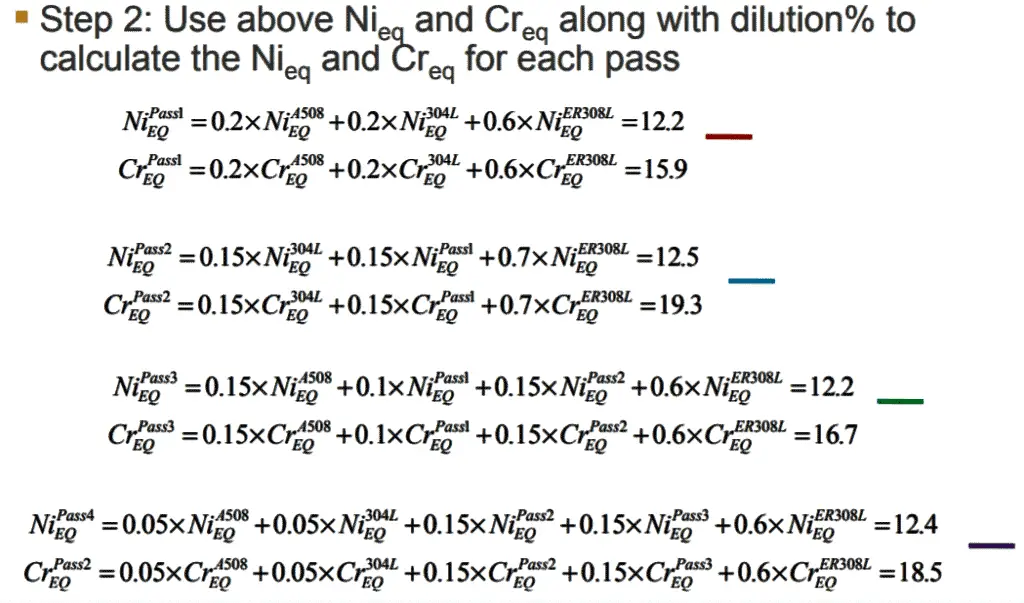

Practical use of WRC-1992 Phase Diagram

Example of Practical Use of WRC-1992 diagram

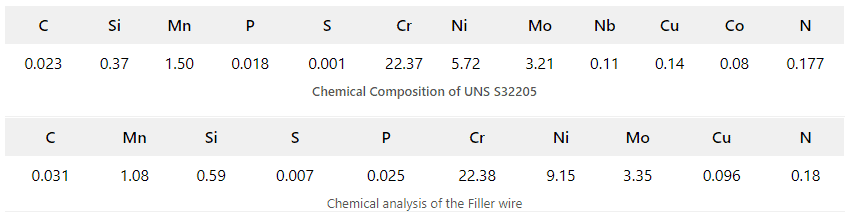

In this example given below, we have considered weld metal of S32205 Duplex stainless steel. The weldment is deposited with ER2209 TIG filler wire.

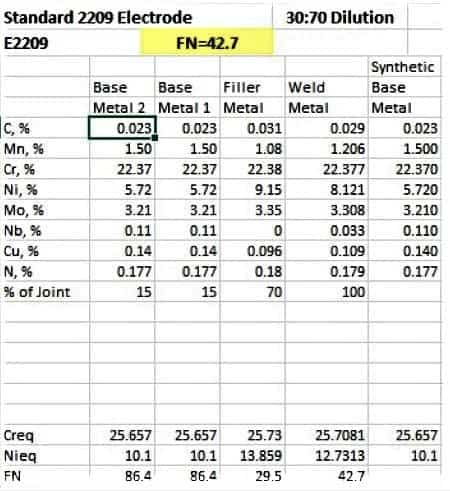

We will use the WRC-1992 diagram to find the FN Number in this case. Considering a weld dilution rate of 30% from the base material (Duplex stainless steel) and a balance of 70% from the welding filler wire (ER2209).

With this assumption, the calculation of the Ferrite Number will be as stated below:

Step 1– Determine Chemistry of Base metal & weld Metal

Find the Chemical analysis of base material & Filler wire

Step -2 Calculate the Chromium & Nickel Equivalent

Using the equation given earlier for Cr Eq and Ni Eq, we shall calculate the Cr & Ni Equivalent respectively. Cr equivalent will be plotted on the X-axis and Ni- Equivalent on Y- Axis.

Step 3 Plotting the Cr & Ni Eq on the WRC Diagram

In this below plot of the valves calculated above, Duplex stainless steel base metal is stated by the Point B (where Cr Eq-25.7 & Ni Eq-13.8).

The Cr Eq for filler wire is 25.73 & Ni Eq is 13.859. Similarly, based on the weld dilution rate (30%) considered, we have the point C where we can predict the FN Number for the deposit weld as FN 42.5.