Lot of people are curious to know which rod to use to Weld Stainless to Mild Steel or any other alloy. In this Post, I have provided detailed information on welding stainless to mild steel, carbon steel, low alloy steel as well on dissimilar metal welding.

Welding of Stainless Steel to Mild Steel/ Carbon steel/ Low alloy steel

This post explains in detail about Welding of Stainless Steel to Mild Steel or Carbon Steel or low alloy steel using Stick Welding, TIG Welding, MIG Welding, and Flux Cored Arc Welding (FCAW) processes.

The post guide you on the type of welding rod to be used, Welding Gas to be used, and other important information that aid in this welding.

First, let us get familiar with what is Dissimilar Metal welding & how it is related to this topic.

Dissimilar metal welding (DMW)

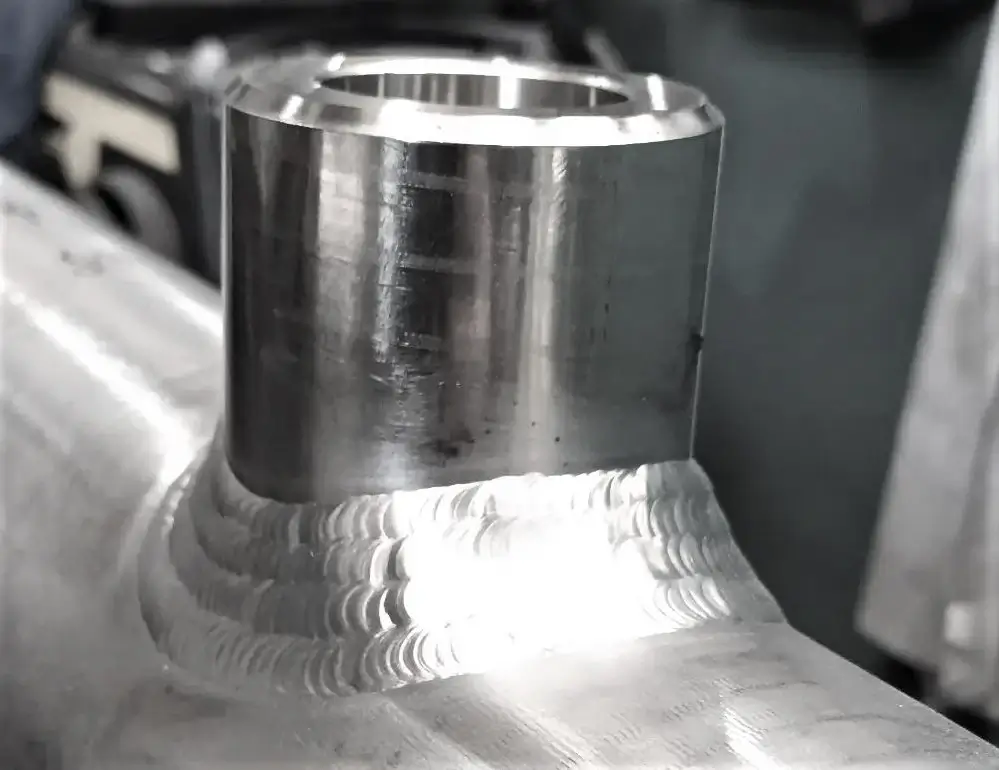

Dissimilar metal welding (DMW) is applied for welding of different metallurgical alloys for example welding stainless steel to carbon steel.

The requirements of DMW are quite common in oil & gas, power plant, and chemical plants to weld transition welds. E.g., austenitic stainless-steel tubing material is generally used for high-temperature applications in refineries.

But below some temperatures, carbon steel is also suitable to withstand this temperature. And it’s not practical to use stainless steel for these areas.

The best option as economical is to join the stainless steel pipeline to a carbon steel pipeline instead of using the full stainless steel option. Such type of combinations occurs frequently in power plant and oil & gas plants.

Consideration for Dissimilar Welding

The essential features to be considered when welding dissimilar metals are:

The melting temperatures of the two metals are concerned: Widely differing temperatures can mean that the higher melting point may not melt or could provide a disproportionately small amount of the weld pool.

Coefficients of Expansion: Widely differing coefficients of thermal expansion can provide undue stressing on the low expansion alloy during any thermal cycling subsequent to welding.

There may even be a problem during initial cooling that could leave undesirable internal stress in the join.

Sometimes it is necessary to provide a buttering layer with an intermediate coefficient of expansion.

Coefficients of thermal conductivity: If one metal in a bond has a high thermal conductivity this side of the weld will be at a lower temperature and this could lead to non-uniform join properties.

Stick Welding or TIG Welding of Stainless Steel to Mild Steel

Stainless Steel & Mild Steel are having different coefficients of Thermal Expansion & chemical composition.

You can continue reading this post for detailed metallurgical suitable welding rods for TIG & Stick Welding of Stainless Steel to Mild Steel or Carbon Steel welding.

In short, Stick Welding of Stainless Steel to Mild Steel (Carbon Steel) shall be made using an E309L type welding rod.

The usability characteristic such as E309L-15, E309L-16, or E309L-17 is not an issue. Click the below Link to Know the differences between these usability characteristics.

Difference between E309L-15, 16 17, E316L-15,16 and 17

TIG Welding of Stainless Steel to Mild Steel shall be made using ER309L type welding rod. There are other TIG Welding fillers available for welding of mild steel to stainless steel as explained further in this post.

Welding of stainless steel to mild steel/ Carbon steel/ Low alloy steel (Temperature up to 600 °F (315 °C)

The choice of consumable must cover not only the strength requirement in the weld. Other factors such as melting point relative to the parents, color, harmful phases that might occur, and corrosion possibility all have to be included in the considerations.

Carbon Steel to Stainless Steel Welding Electrode

The most common Carbon Steel to Stainless Steel Welding Electrode/ filler wire used to join stainless steel or duplex stainless steel to Carbon Steel or mild steel is E309L/ ER309L (Stick welding/ TIG-MIG rod) for normal temperature service. For high-temperature Nickel, base consumables are preferred.

Here, E309L, ENiCrFe-2, ENiCeFe-3 & ENICrMo-3 are Stick Welding or SMAW Consumables. Their equivalent for TIG/ MIG shall be: ER309L, ERNiCr-3 & ERNiCrMo-3.

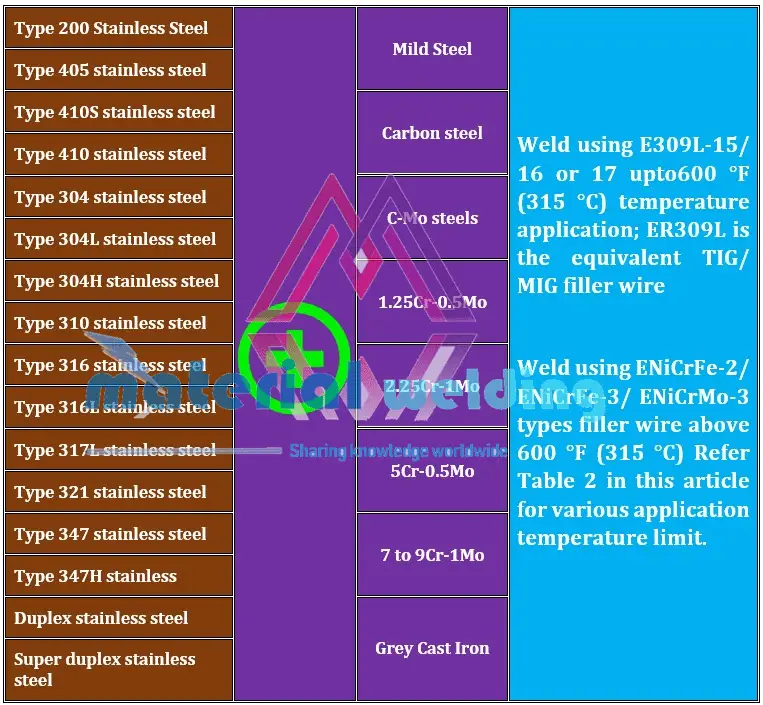

The table below shows the combination of various dissimilar welding combinations between stainless, duplex stainless steel & carbon steel, and Cr-Mo steels.

Click here to Get Guide on How to Weld various materials

Welding of ferritic steel ( P No. 1, 2, 3, 4 & 5) to other ferritic steel, the welding wire should have matching chemistry of base metal or match to diluted weld chemistry.

Welding of pressure parts, the filler wire must match the chemistry of the pressure part material.

Welding of ferritic steels (P-No. 1 to P-No. 5 and P-No. 15E) to:

- Martensitic stainless steels (P-No. 6); or

- Ferritic stainless steels (P-No. 7); or

- Austenitic stainless steels (P-No. 8), the welding wire shall be selected based on:

1) Welding rod/ filler wire 309 and Type 309L can be used for design temperatures up to 600 °F (315 °C). For temperatures above 600 °F (315 °C), Nickel base welding consumables (E.g. ENiCrFe-3, ERNiCr-3, etc.) shall be used.

Welding of Mild steel or low alloy steel (P1, P3, P4 & P5) to Stainless steel (P6, P7 & P8) for high-temperature applications

2. Nickel-base alloy filler materials may be selected using design conditions shown in the Table below:

Welding Stainless to Mild Steel with 7018

It is possible to weld Stainless Steel to Mild Steel or Carbon Steel using E7018 or ER70S-2/ ER70S-6 Welding rods although it is not suggested to do so. The reasons are:

- The weld will be prone to cracking due to the formation of a martensite structure.

- The stainless steel HAZ will have a reduction in chromium & which will reduce the corrosion resistance of the stainless steel material.

- Low strength of the welding joint.

The optimal weld properties between the dissimilar welds of Stainless Steel to Mild Steel or Carbon Steel are achieved by using an austenite base welding rod such as E309L or ENiCrFe-3/ENiCrFe-2 or other recommended welding rods in this post earlier.

Flux Core Arc Welding (FCAW) Stainless Steel to Mild Steel

Flux Cored arc welding of Stainless Steel to Mild Steel is carried out using the E309LT-1 FCAW Wire. 75/25 Welding Gas mixture shall be used when welding Stainless steel to carbon steel for gas shielding.

E309LT-1 FCAW wire is also used for welding Carbon Steel to Stainless Steel using the Flux Cored Arc Welding process.

75/25 welding gas, gas cylinder bottle sizes

Can You MIG Weld Stainless Steel to Mild Steel?

Simple Answer- YES. Stainless Steel to Mild Steel/ Carbon Steel Welding shall be carried out using ER309L (AWS A5.9 specification) type Filler wire.

You can also use ER309 (MIG wire with higher carbon content) for welding Stainless Steel to mild steel but the weld with high carbon are not suitable for heat treatment.

The Welding Gas used for Stainless Steel to Mild Steel/ Carbon Steel MIG welding is Argon + 2% oxygen. You can Short arc or spray arc for welding.

A spray arc is good for welding in a Flat position while the short arc is beneficial for welding in out of position welding.

Click the below link to learn about different types of Shielding gases used in TIG, MIG & FCAW Welding of Stainless Steel Materials.

Shielding gases of TIG MIG and FCAW welding of stainless-steel, duplex steel

Welding Stainless Steel to Mild Steel Exhaust

Many times we need to perform welding of stainless Steel parts (such as catalytic convertors) to Carbon steel piping in trucks or other vehicles or motorcycle parts.

It is possible and handy to perform these material welding combinations. Below are the suggested rods for different welding processes to weld Stainless Steel to Mild Steel exhaust:

- Stick Welding: Use ER309L or ER309 welding rod

- TIG or MIG Welding: Use ER309L/ ER309 type filler wire using Argon + 2% oxygen Welding Gas.

- Flux Cored Arc Welding (FCAW): Use E309LT-1 FCAW Wire with 75/25 Welding Gas mixture.

Use of the Schaeffler diagram – Joining stainless steel and mild steel

The Schaeffler diagram is helpful to estimate/predict the microstructure for dissimilar weld joints. Based on the filler wire, and base metal chemistry microstructure prediction can be carried out.

It is an indication of the constituents that will be present in the microstructure for various values of the nickel and chromium equivalent percentages.

Watch this interactive video on Schaeffler Diagram and its practical uses:

Schaeffler Diagram & Its Uses.

Dissimilar metal welding with Nickel Alloys

These alloys are most sensitive to sulfur as well as phosphorus, lead, and zinc. In determining whether a weld is likely to give a problem, the composition of the weld pool should be estimated using the proportional method.