What is SS 321 Stainless Steel?

SS321 is Austenitic Stainless steel having the nominal composition (wt. %) of this classification is 19.5 Cr, 9.5 Ni, with titanium (5 times the amount of Carbon) added.

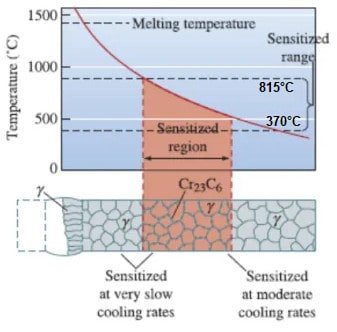

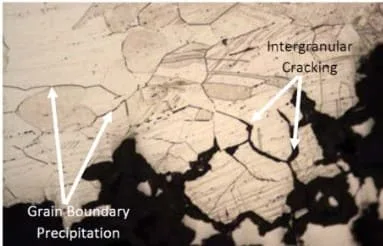

The role of titanium is similar to the niobium in SS347 by minimizing intergranular chromium carbide precipitation and hence improving the resistance to intergranular corrosion also called IGC.

The added titanium minimizes or mitigates the sensitization of carbide precipitation at welding stage and also in-services in the temperature range of 800 ° F- 1500 ° F (425-815°C) .

The alloy offers higher corrosion resistance compared to other austenitic stainless steel such as 304, 310, and 316L types.

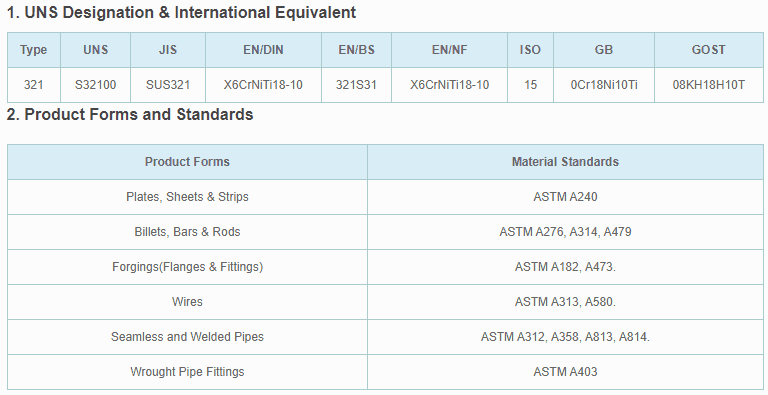

Material Specification for SS 321

The UNS number for 321 is SS32100. The EN equivalent material grade of SS 321 is X6CtNiTi18-10. The detailed material specification and equivalent grades of SS321 are given in the below table.

Click here to learn about Types of Stainless steel & their properties.

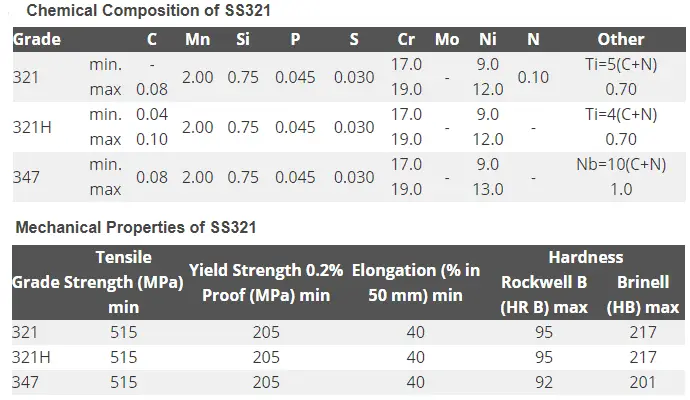

Chemical and mechanical properties of SS321

The Chemical and mechanical properties of SS321 are given in the below table. The minimum tensile strength of 321 is 75Ksi, the Yield strength is 30 Ksi with an elongation of 40%, and hardness value of 95 HRB.

The chemical and mechanical properties comparison of SS321 to SS347 are also shown in the below table.

SS321 vs. SS347

Both SS321 and 347 are austenitic stainless steel grades having similar mechanical properties and major alloying elements.

The only difference is the microalloying elements. While Titanium is added into 321 grade to stabilize, SS347 grade is stabilized using Niobium (Nb) or also called Columbium. A detailed comparison is shown in the above table for user reference.

SMAW, TIG-MIG Welding electrode for SS321

SMAW or stick welding of SS321 is carried out using an E347-type electrode. As, due to highly oxidizing Titanium, It’s not possible to transfer Ti in the SMAW process where the shielding contains highly reactive gases such as oxygen, CO2, and Co.

This is the reason that no 321-type electrodes are available for SMAW or stick welding.

TIG and MIG welding of SS321 is carried out using ER321-type electrodes. ER321 gives a weld metal having similar base metal properties.

ER321 filler wire is used for welding stainless steel having similar chemical composition. As the wire contains titanium which is a highly oxidizing metal, it is a must to use an inert shielding gas so that titanium can be transferred to the weld successfully.

Due to this reason, SS321 welding electrodes for stick welding or SAW are not available in the market.

If titanium is added to the stick welding rod or in the wire of SAW, it will react with the oxygen present due to flux or coating burning and will get oxidized.

Use below link to get filler wire selection chart for various material welding.

Welding Electrode/ Filler wire/ Filler metal Selection Chart

Shielding/ Purging and backing gases for SS321 welding

Pure argon is used for shielding and purging. To learn in details about shielding gases used for stainless steel welding.

Click here Shielding gases of TIG MIG and FCAW welding of stainless-steel duplex steel.

Preheat and interpass temperature

No preheating is required for SS321 materials. Welding in cold places require heating to ambient temperature to remove any moisture.

Interpass temperature when welding SS321 shall be kept below 200 Deg Celsius or 400 Degree Fahrenheit.

When welding stainless steel, especially austenitic stainless steel to duplex stainless steel, a high heat input must be avoided to control the formation of ferrite as well as high stresses which can result in distortion.

Welding SS321 to Mild steel

SMAW welding can be done using E309L and TIG and MIG welding using Er309L type filler wire. ENiFeCr-3 type electrode can also be used to join 321 to carbon steel or low alloy steels such as Cr-Mo steels.

Welding using low heat input is recommended to avoid excessive dilution. No preheat is required for SS 321 although, preheating shall be applied on low alloy side material which can have risk of hydrogen cracking.

Welding 321 to 347 and 304

Welding of SS321 to SS347 can be made using SMAW process with E347 type welding electrode. TIG-MIG welding of 321 to 347 shall be carried out using ER321 or ER347 type filler wire only.

When welding 304 type stainless steel to 321, welding can be carried out using ER321 type electrode or ER308L type. It is recommended to use ER321 although for such welding applications.