How to make the selection of welding electrodes or filler wire?

Looking for a Welding Electrode and Filler Wire Selection Chart? Download our comprehensive PDF chart to simplify your electrode and filler wire selection process for any material.

Discover the key factors to consider, such as base metal compatibility, welding position, and desired mechanical properties when choosing the right filler wire or electrode for your job.

The selection of the right welding electrodes or filler wire is an expert task performed by Welding Engineers based on factors:

- Base material types, grade e.g. Stainless steel or carbon steel, SS316, ASTM A106, etc.

- Similar material welding or dissimilar welding.

- Joining or weld overlay application.

- Metallurgy of the material, its physical, and chemical properties.

- Service conditions e.g. room temperature elevated temperature, deep-sea, etc.

- Type of available welding process.

- Availability of welding consumables in the market.

- Type of welding joint and applicable welding stresses.

- The thickness of the base metals to be joined

- Anticipated cost, and quality requirements.

These are the main summary of the points to be considered for choosing a welding electrode although there are various other associated factors that need to be considered too.

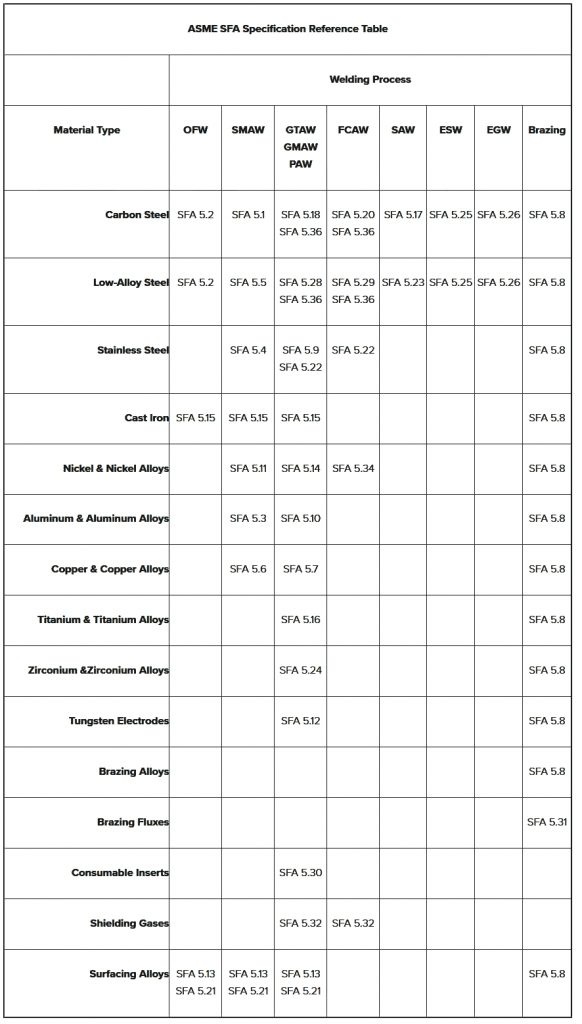

Finding Electrode for different types of materials

An easy way to find an electrode for a known type of material is via ASME Section IIC. ASME IIC contains 36 SFA from SFA 5.1 to SFA 5.36. A summary of these SFA numbers and their material types is shown in the below table.

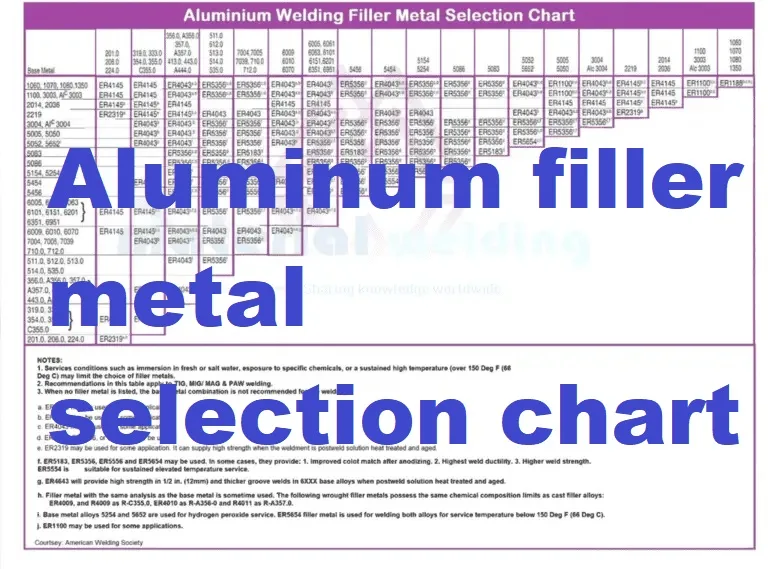

Click here, For the Aluminum Welding Selection chart & guide.

Welding Electrode/ Filler wire/ Filler metal Selection Chart

Use these charts to easily locate matching, suitable electrode or filler wire for welding to join various similar and dissimilar welding.

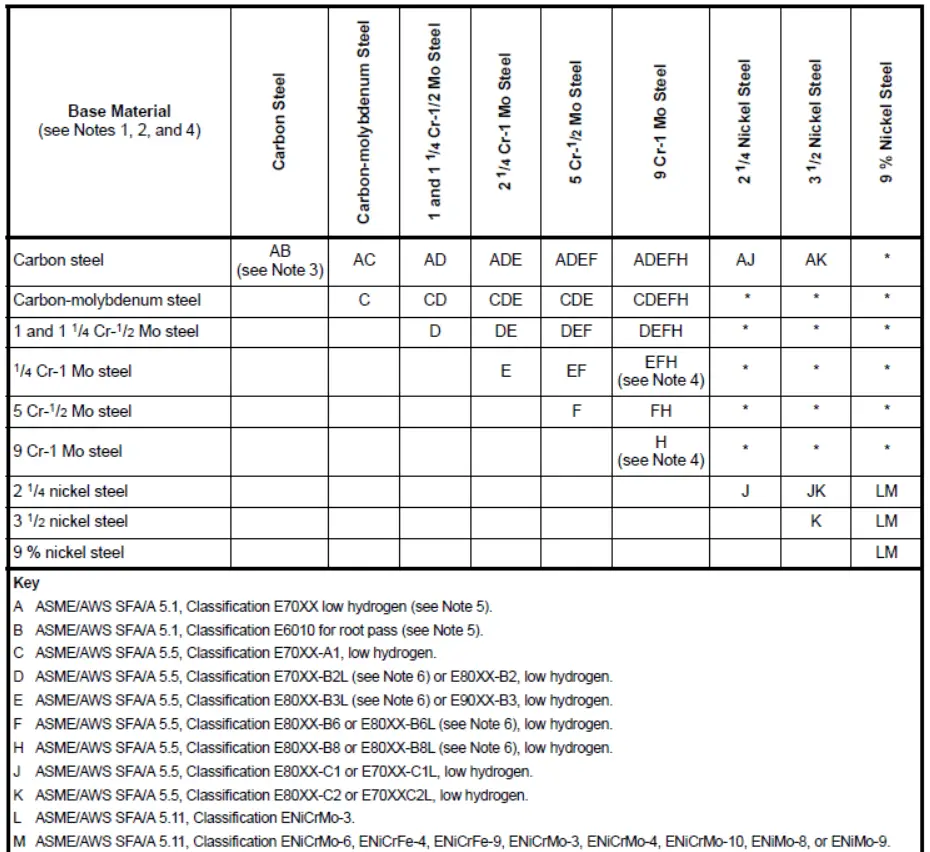

Welding electrode selection Chart for Carbon steel, Low alloy steel, Cr-Mo Steel

Welding electrode selection for carbon steel to carbon steel, C-Mo, Cr-Mo & Nickel steels are given in the below chart. Most of the carbon steel is welded using an E7018 stick rod or ER70S-6 TIG/ MIG filler.

These electrode’s deposit strength is higher than most commonly used carbon steel such as ASTM A36, ASTM A 516, S275 or S375, ASTM 105, A106, etc.

Refer to the below chart to find dissimilar weld combinations also. For example, if you wish to weld Carbon steel to 5Cr-1/2Mo, you can use E7018, E8018-B2, or E8018-B3 Stick rod or their equivalent TIG/ MIG filler such as ER70S-6, ER80S-B2 or ER80SB-3.

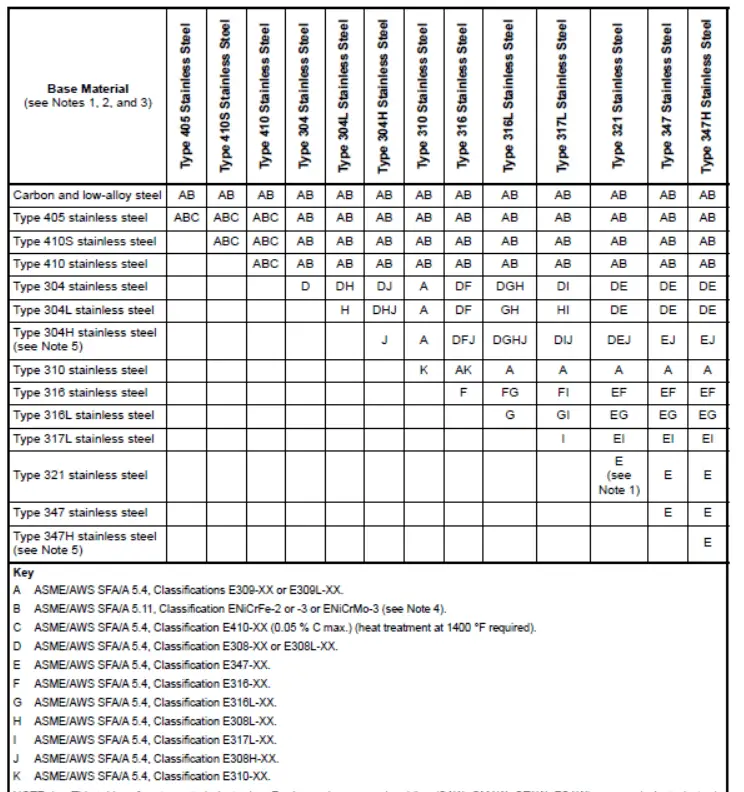

Welding electrode selection Chart for Carbon steel to stainless steel, All Stainless Steel

The below chart gives very detailed guidelines for stick welding (SMAW) or equivalent TIG/MIG filler wires for different types of stainless steel welding.

In these consumables, XX means -15/ -16 or -17 type. For example, E309L-XX, you can use either E309L-15 or E309L-16, or E309-17.

Click here to learn the difference between -15, -16, or -17 type electrodes.

When choosing stainless steel electrodes, it is very essential to consider the matching electrodes to ensure the right corrosion protection properties of the weldment.

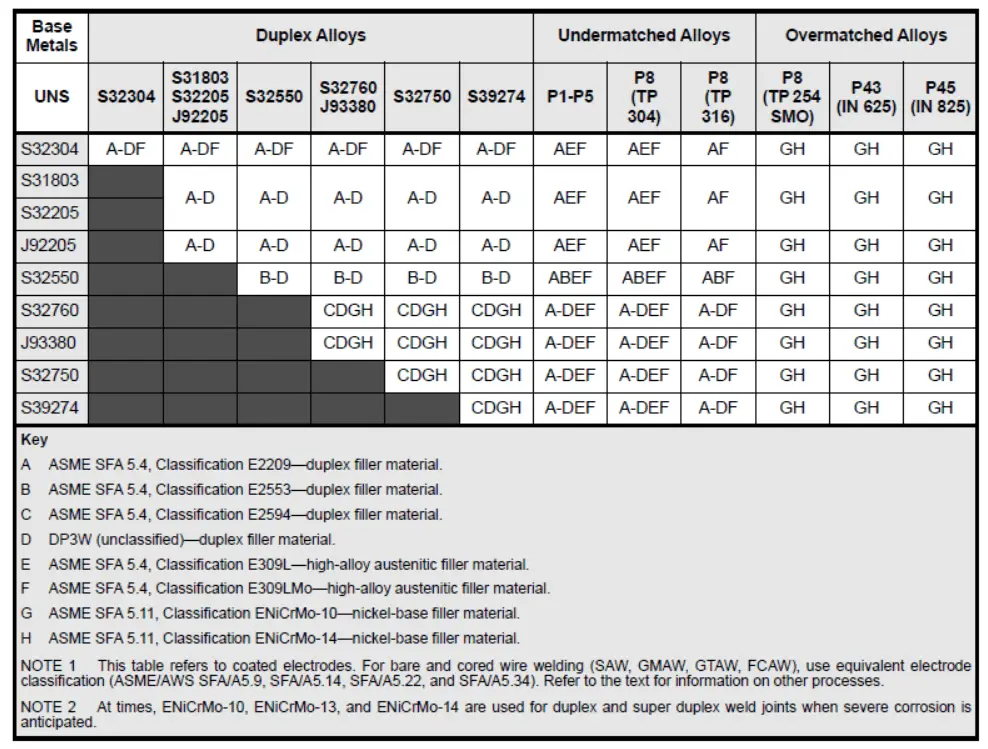

Welding electrode selection Chart for Duplex Stainless steel, Duplex to carbon steel and Stainless steel

Use this chart to find welding electrodes for welding duplex stainless steel, Super Duplex stainless steel, and welding Duplex stainless steel to Carbon steel, stainless steel, and Nickel alloys.

TIG/ MIG equivalent of these given stick electrodes/ SMAW Electrodes are:

- E2209 = ER2209

- E2553 = ER2553

- E2594 = ER2594

- E309L, E309LMo = ER309L/ ER309LMo

- ENiCrMo10/ ENiCrMo14 =ERNiCrMo-10/ ERNiCrMo-10

Welding rod sizes doesn’t affect the welding electrode selection as it doesn’t affect the material mechanical properties in any manner.

Aluminum filler metal selection chart

Click here for Aluminum filler metal selection chart.

Further resources:

- What is the Best Welding Rod to use for Cast Iron- Find it Here.

- Complete Guide for Welding Rod Types, Meaning and Uses

- TIG welding rod selection chart pdf.