What is 2205 Duplex Stainless Steel

2205 is a Duplex Stainless Steel containing 22%Cr along with Molybdenum and Nickel as alloying elements.

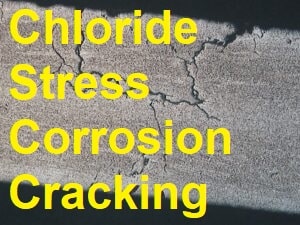

2205 is widely used in oil & gas industries as it offers very good corrosion resistance against seawater corrosion, chloride stress corrosion cracking (SCC) at temperatures of 150°C, and pitting corrosion.

Material Specification

ASTM/ASME material Specification: A240 UNS S32205/S31803

European/ ISO Standard:1.4462 X2CrNiMoN 22.5.3

AFNOR: Z3 CrNi 22.05 AZ

DIN (German): W. Nr 1.4462

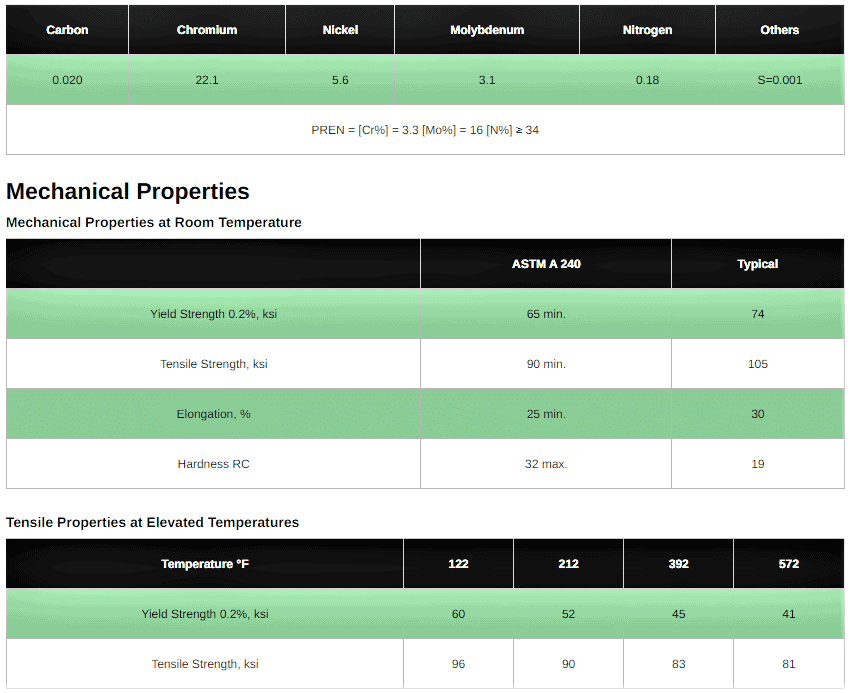

Chemical and Mechanical properties of 2205 DSS

The chemical and mechanical properties of ASTM A 2205 (UNS 32205) are given in the below table.

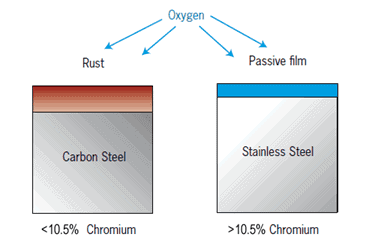

As you will notice, the Chromium percentage is around 22%, so we simply say this grade is Duplex Stainless Steel.

Other material grades such as UNS No 32750 contains Chromium contains 25% Chromium, thus known as Super Duplex Stainless Steel.

Chemical properties of 2205 DSS

What is PREN, PREN formula and pitting corrosion?

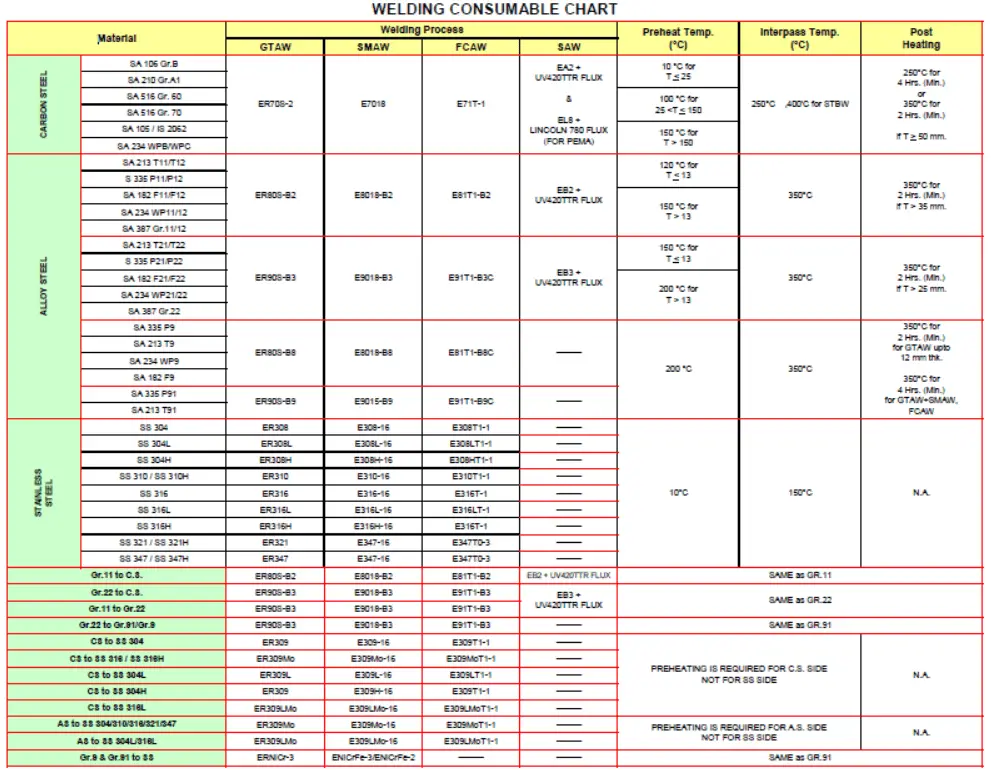

SMAW/ TIG-MIG Welding of 2205

SMAW or stick Welding of 2205 Duplex Stainless Steel shall be carried out using ASME SFA 5.4, Classification E2594—duplex stick Electrode.

TIG/ MIG can be made using ER2594 type filler wire. Another electrodes/ filler wire available in the market is DDP3W (unclassified classification)—duplex filler material can also be used for welding.

SMAW/ TIG-MIG Welding of 2205 to Carbon Steel

SMAW or stick Welding of 2205 Duplex Stainless Steel to Carbon Steel shall be carried out using ASME SFA 5.4, Classification E2209 or E309L or E309LMo. TIG/ MIG can be made using ER2209 or ER309L or ER309LMo type filler wire.

Welding duplex 2205 to 316 stainless steel

Welding duplex 2205 to 316 stainless steel is straightforward although need to select the right welding rod and control the welding heat input.

Using the correct welding rod/ Filler wire, high quality welds can be achieved between Duplex 2205 and 316 Stainless steel material.

Welding of duplex 2205 to 316 stainless steel is carried out using:

- E2209 Stick Welding rod or ER2209 TIG-MIG Filler wire rod

- E309L welding electrode or ER309L TIG-MIG Filler wire rod

- E309L welding electrode or ER309L TIG-MIG Filler wire rod

SMAW/ TIG-MIG Welding of 2205 to Stainless Steel (SS304L, SS316L)

SMAW or stick Welding of 2205 Duplex Stainless Steel to Stainless Steel shall be carried out using ASME SFA 5.4, Classification E2209 or E309L or E309LMo.

TIG/ MIG can be made using ER2209 or ER309L or ER309LMo type filler wire. Either E2209 or E309LMo shall be used for welding 316L to Duplex Stainless Steel.

E309L or ER309L shall not be used for welding SS316L to Duplex stainless steel, as it contains less amount of Molybdenum.

Shielding gases of TIG MIG and FCAW welding of stainless-steel duplex steel

Preheat-Interpass Temperature for 2205 Welding

Preheating is not required for duplex stainless steel as it will increase the heat accumulation during welding which will degrade the material microstructure balance.

If moisture removal is required, the duplex steel can be heated at 100°C (210°F) so moisture will evaporate.

Care must be taken not to heat for a longer duration and careful temperature monitoring must be carried out.

Interpass temperature

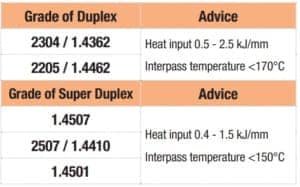

Control of interpass temperature for duplex stainless steel welding is highly essential. The interpass temperature depends on the type of Duplex stainless steel as follow:

- Interpass temperature for Lean duplex and duplex stainless steel grades: 150°C (300°F) ,maximum,

- Interpass temperature for Super duplex stainless steel grades: 100°C (210°F)

A high interpass temperature will slow down the cooling rate during solidification and will result in detrimental elements precipitations (intermetallic phase, nitrides, or carbides) in the weldment.

Post-heating

Post-heating is for duplex stainless is not advised. Temperature limits as given above for maximum interpass temperature shall be considered as a guideline for upper-temperature limits during welding.

A high temperature in this range is detrimental for the duplex steel metallurgy. High heat input during welding will increase the ferrite content in the weld & HAZ beyond the acceptable range. This in turn will compromise the corrosion resistance of the material.

Heat Input for 2205 Welding

The maximum heat input for 2205 Welding shall not exceed 2.5Kj/mm. The interpass temperature shall be kept at less than 170 Deg Celsius or 340 Degree Fahrenheit.

Below Table is the general guidelines on welding heat input for the satisfactory mechanical results in the weldment. Heat Input can be calculated using our ONLINE HEAT INPUT CALCULATION TOOL.