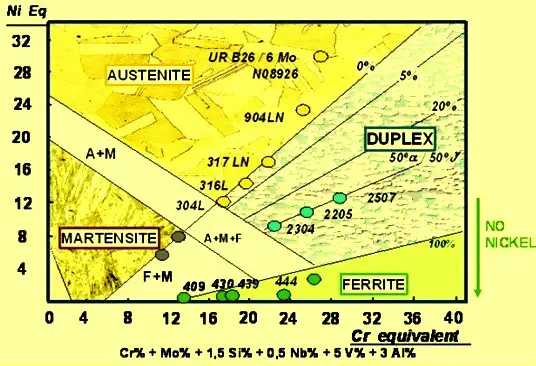

Ferrite Testing is a process used to determine the ferrite content (delta ferrite) in Duplex stainless steel (e.g. 2205 grade) and austenitic stainless steels (e.g. 316, 321 Grade).

Ferrite testing is important because it can be used to predict the behavior of austenitic steels and duplex stainless steels during welding.

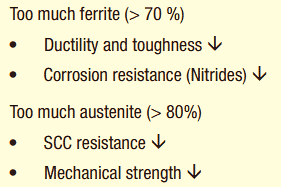

For example, steels with high ferrite content are more likely to have reduced corrosion resistance than those with low ferrite content.

A too low ferrite content makes material or weldment highly susceptible for hot cracking or also called solidification Cracking.

High ferrite content also decreases the mechanical properties (mainly tensile, toughness & hardness) of the material.

Ferrite content can affect the mechanical, corrosion and electrical properties of a material. It is also equally important for welded parts final resultant properties.

Ferrite Testing methods or techniques

The determination of the ferrite content in austenitic steels can be made either metallographically ( E.g. planimetry, lineal analysis, or differential point counting) by using micro-sections (destructive methods) or magneto-inductively ( for example using Ferritoscope) (nondestructive methods) directly at the weld.

Other methods such as using electron diffraction such as X-ray diffractometry (XRD) or electron backscatter diffraction (EBSD) are also used but they are quite expensive.

Mostly, measurement using image analysis from the microscope and manual measurements using Ferritoscope are widely used in the industries due to their ease to use and quicker operations.

However, in magneto-inductive testing, the reading is a function of the chemical composition of the alloy.

Therefore, when dealing with high ferrite content the indicated ferrite content does not correspond to the actual content in the material, since high-alloyed ferrite tends to have a weaker magnetic reaction than the same ferrite content does with a lower alloy potential.

For these reasons, the Ferrite number (FN) was introduced for indication of the content of ferrite (EN ISO 8249 and EN ISO 17655).

Calculate ferrite content in stainless steel & duplex stainless steel

Ferrite Testing & measurement using Image analysis

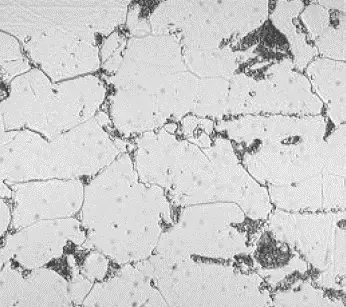

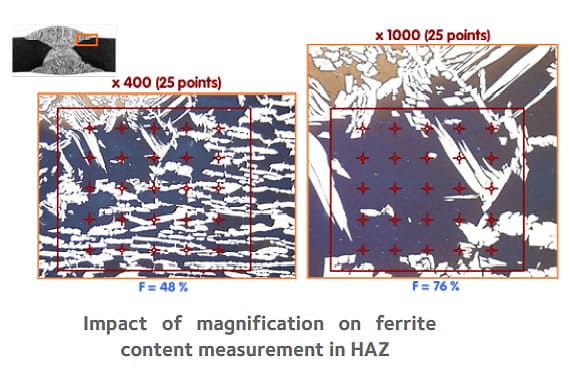

The image analysis method for the ferrite testing measurement requires polished macro samples that are analyzed under high magnification.

The Light optical microscope is used with special software to check the small areas of each phases presents.

The method is most reliable along with point counting, although the operator skills are very important.

The accuracy of the method depends on the macro sample preparation, etching, and polishing quality as they can highly affect the outcome.

The technique follows the guidelines of ASTM E 562 (Standard Test Method for Determining Volume Fraction by Systematic Manual Point Count) and requires that the magnification shall be adequate to allow clear resolution of the microstructure.

For stainless steel, duplex stainless steel, and other nickel base alloy, usually, magnification in the range of 500X to 1000X is used.

Here, as the magnification is increased, the area of the field will decrease. Hence, multiple reading are required in this case.

The process of the image analysis method is having a different number of steps such as cutting the specimen, preparing the micro specimen, polishing, and etching followed by final measurement and then reporting the results. All these steps make this technique time-consuming.

Ferrite Testing using Ferritoscope

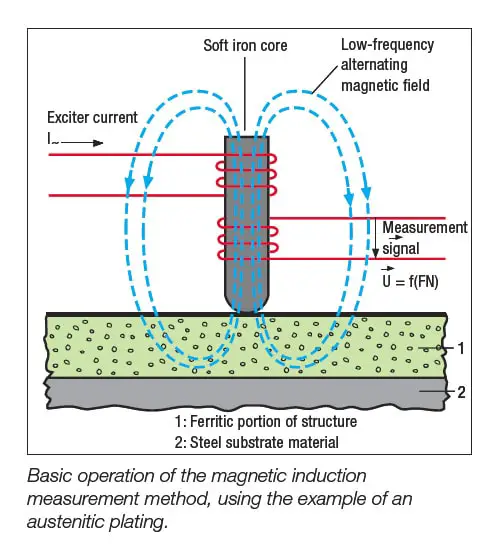

Ferritoscopes are handheld instrument works on the principle of magneto-inductivity. It relies on the technique of magnetic induction to make the ferrite measurement.

During testing, ferritoscope measures all magnetic areas and leaves all non-magnetic microstructure, thus producing an overall ferrite content in the austenitic phase.

Ferritscope is a non-destructive and fast result-producing technique for ferrite measurement in the field.

The accuracy however depends upon the equipment calibration, operator skills, and surface conditions.

Equipment needs to be calibrated before use using the calibration blocks otherwise the results can be misrepresented.

Simple Ferrite Calculation methods

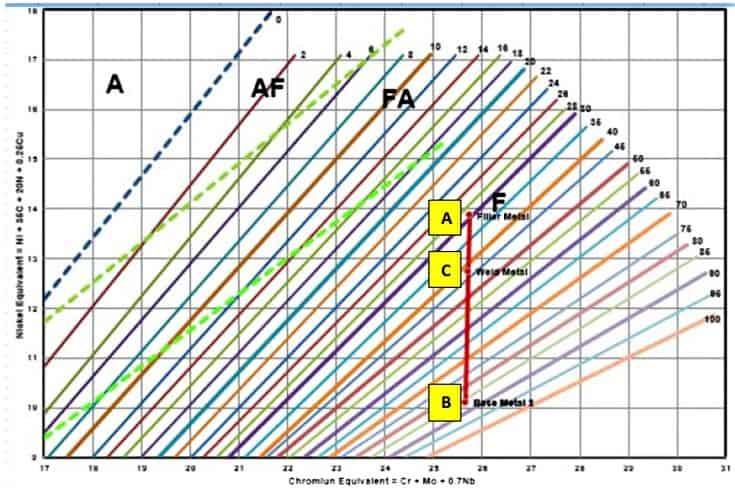

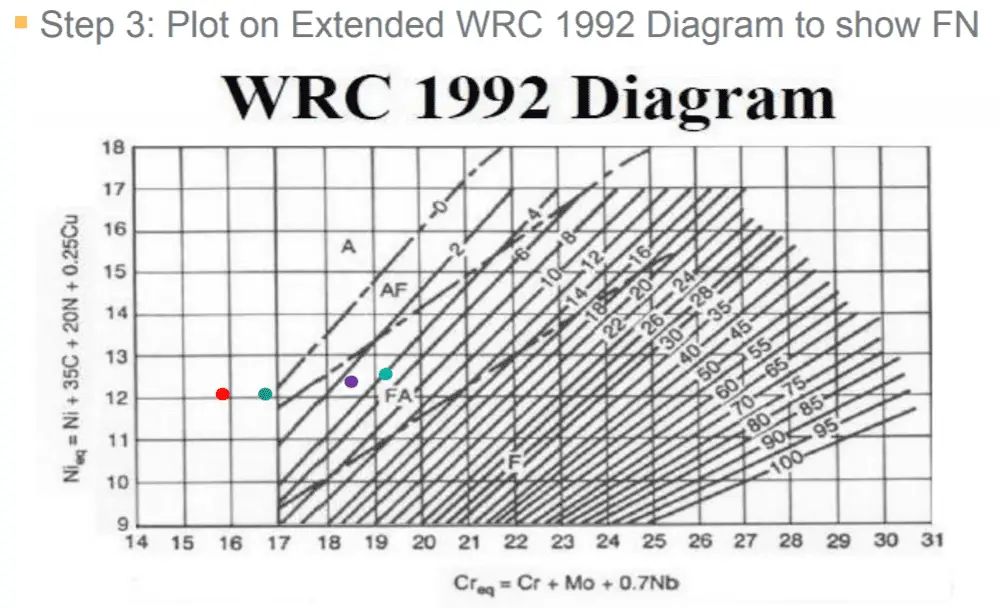

Weld metal or weld deposit ferrite content can be estimated using is chemistry with the help of ESPY diagram (results in ferrite percent F%) or the WRC-1992 diagram (results in FN).

The other methods (SCHAEFFLER or DELONG) which do not consider nitrogen and copper contents cannot be used for duplex welds.

ferrite number to ferrite percentage conversion

You can easily convert ferrite number (FN) to ferrite percentage using the formula. Up to 10 FN Ferrite is equal to the percent ferrite (FN%). So up to FN 10, it will be the same Ferrite percentage value.

To convert from ferrite % to FN, the following can be used:

- For 22 % Cr duplex stainless steel, ferrite % = 0.7 × FN;

- For 25 % Cr duplex and super duplex stainless steels, ferrite % = 0.65 × FN.

- Ferrite Number (FN) = (ferrite%) x [-0.025813 (Iron)2 + 5.408679 (Iron) – 102.3902]/100

Another method to convert FN to Ferrite percentage is using the Delong diagram.

Difference between Ferrite Number & Ferrite Percentage

Ferrite Number is known as (FN) and Ferrite percentage is written as F% where F is a numeric value.

As highlighted earlier, up to FN 10 it is equal to F% but with the higher value, these both terms do not correspond to each other and vary.

The WRC (Welding Research Centre, America) Subcommittee has adopted the term Ferrite Number (FN) to be used in place of percent ferrite, to clearly indicate that the measuring instrument was calibrated to the WRC procedure.

The Ferrite Number, up to FN 10 it is equal to F% but with the higher value, these both terms do not correspond to each other and vary.

This is practice followed by all welding industries as on today. During in field testing and following the standard calibration methods, is it expected to have some variation in ferrite measurements about ±5 percent, or at the most, ±10 percent of the measured ferrite value and this need to considered in the acceptance criteria.

Ferrite number to ferrite percentage conversion

The amount of ferrite in an alloy is measured by its ferrite number. This number can be converted to a percentage, which will tell you how much of the alloy is made up of this essential element.

Converting ferrite numbers to percentages can be done by using a simple formula. To convert from ferrite % to FN, the following can be used:

-For 22 % Cr duplex stainless steel,

- Ferrite % = 0.7 × FN;

For 25 % Cr duplex and super duplex stainless steels,

- Ferrite % = 0.65 × FN.

What is the roles of Ferrite in Welds?

In welding ferrite is beneficial and detrimental both- but this is a property that is reviewed & considered during design.

Ferrite is not good when we need material for cryogenic temperature application but in welding ferrite is very good as it minimize the chances of hot cracking or fissures (micro crack visible at minimum 50X magnification) during welding.

It is good to have some amount of ferrite in austenitic stainless steel welds to resists the weld cracking that might occurs during solidification.

Having ferrite in welds avoid micro cracks which could otherwise propagate during product service and can be serious damage. Ferrite improve the strength in steel and maintain lower hardness.

The effects of ferrite in materials are explained in the below table.

Ferrite Test Acceptance Criteria ASME

Ferrite Acceptance for Duplex Stainless Steel

For duplex stainless steel, the minimum and maximum range of ferrite number in the welding, HAZ and base metal shall be as following (Ref: API 582):

- Weld metal—30 % to 65 %,

- HAZ—40 % to 65 %,

- Base metal—40 % to 60 %.

NOTE 1 Ferrite content down to 25 % may be acceptable for the weld metal if corrosion or other tests are satisfactory to the purchaser.

Nickel being a strong austenitic stabilizer eliminate the need to check ferrite content for weld which are welded using a nickel base consumables such ERNiCrMo-3 or ENiFeCr-2 etc.

NOTE 2 To convert from ferrite % to FN, the following can be used: For 22 % Cr duplex stainless steel, ferrite % = 0.7 × FN; For 25 % Cr duplex and super duplex stainless steels, ferrite % = 0.65 × FN.

Ferrite Acceptance for Austenitic Stainless Steel

Ferrite content or FN number for austenitic welds are usually restricted based on the welding consumable used.

Most of welding consumables in the E3XXX or ER3XXX classification as per specification AWS A5.4 and 5.9 are fully austenitic type.

Examples of such rods are: E310 types, E316LMn, E320, E320LR, E330, E383, and E385 etc. Welds made with ER316 or E316 usually may have little ferrite as it gives better corrosion protection.

The ferrite number in above electrodes are kept above FN4 to have better crack resistance properties.

Welding rods such as ER308LMo and E309L, E309LMo can have ferrite (FN) more than FN15. E16-8-2, a special welding rod with low ferrite number is used for welding of sensitized austenitic stainless steel welds are made with very low ferrite content.

welding consumables for duplex stainless steels such as ER2594, E2595, E2209 are made with higher ferrite, generally more than 20FN.

Metallographic Tests

These tests are rarely called for in specifications but they are commonly used for quality control and during inspection to determine weld soundness, to examine the extent and distribution of non-metallic inclusions in the weld, to check the number and arrangement of runs, to determine the metallurgical structure in the fusion zone and the heat-affected zone and to check the depth of weld penetration.

Samples are obtained from a test weld by sectioning or from a production weld by trepanning.

Trepanning means mechanical removal of the weld joint portion in one piece with a special tool, which leaves a recess in the joint which can be easily filled up by welding.

From these samples, macro specimens or micro specimens are prepared by suitable etching procedures as follows:

Macro-Specimens in Metallography

If one wants to avoid grinding and polishing of the cross-sectional surface, one can directly place the specimen in boiling 50% solution of hydrochloric acid in water for approximately 30 min.

Alternately, one may first grind and smoothen the surface with emery wheel or emery paper and then vigorously rub the surface with a piece of cotton fully wetted with a solution of one part of solid ammonium persulphate in nine parts of water by weight.

This rubbing action must be repeated until a clearly defined macrostructure appears on the weld.

After etching, the specimens are washed thoroughly in clear water and wiped dry.

They are then immersed in ethyl alcohol, removed and air dried. If a specimen is to be preserved, a coat of thin, clear lacquer may be applied, so that the surface does not rust in storage.

Micro-Specimens in Metallography

These specimens have to be prepared with a highly polished mirror-like surface and etched with proper chemicals and techniques depending on the type of alloy and the microstructures one is looking for.

The procedure of sample preparation and examination is complicated and requires suitable equipment and a trained metallographer.

Interpretation of the photomicrographs also demands a sound knowledge of physical metallurgy.

Ferrite content test

The ferrite content test is a quick and easy way to determine the amount of ferrite in a sample of austenitic stainless steel.

The test is performed by measuring the magnetic induction of the sample at a specific frequency. The results of the test are used to calculate the ferrite content of the sample.

Ferrite content is a measure of the amount of ferrite present in a steel or iron alloy. It is used as an indicator of the steel’s ability to resist cold work hardening and its weldability.

The test is performed by measuring the magnetic induction of a sample of the material.

The ferrite content test is an important quality control tool for steel and iron manufacturers.

It ensures that the materials they are producing meet certain standards for hardness, wear resistance, and weldability.