Spheroidization phenomena

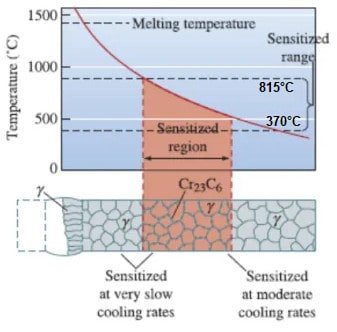

Spheroidization or also called softening refers to the microstructural changes in steel when it is subjected to a high-temperature range of 850 °F to 1400 °F or 440 °C to 760 °C.

At this temperature range, the carbide present in the CS and C-1/2Mo becomes unsteady & pile up as a spheroidal shape or sometimes scattered finely or large piled up carbides. These microstructural changes decrease the material strength mainly creep strength.

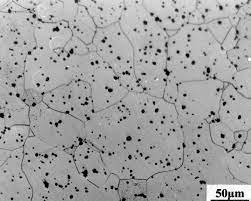

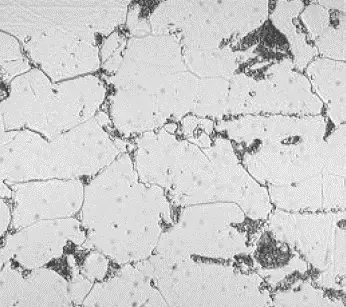

The first picture shows the unaffected base metal of a carbon steel having pearlite and ferrite microstructure.

When this material is exposed to a high temperature above 850-degree Fahrenheit, the Spheroidization takes place as visible by the black area in the below picture.

Watch this Youtube video for full classroom training on API 571 Damage Mechanism- Spheroidization or Softening.

Materials being affected by the Spheroidization

Spheroidization takes place in all common grades of carbon steel used in the refineries. The low alloy steel such as carbon- half moly, and chrome-moly steel from 1 chrome-half moly to 9 chrome 1 moly are included. So basically, a full range of chrome-moly steels are prone to Spheroidization.

Critical Factors for the Spheroidization

The primary factor that affects Spheroidization are the:

- Chemistry of base metal,

- Microstructure, temperature, and time exposure.

If we talk about types of steel, here at first, Normalized steels are at higher risk compared to annealed ones. Secondly, larger grains increase resistance to spheroidization compared to fine grains.

And third, small-grained silicon-killed steels have higher spheroidization resistance than aluminum-killed steel.