Graphitization Meaning & graphitization temperature?

Graphitization means a change in the microstructure of certain carbon steels and 0.5 Moly steels.

During Graphitization, these changes take place in certain grades of Carbon steel and 0.5 Moly steels during exposure to long term operating temperature of 800°F to 1100°F or 427°C to 593°C range.

Graphitization temperature range is 800°F to 1100°F or 427°C to 593°C. This results in the loss of mechanical strength, ductility and, or creep resistance.

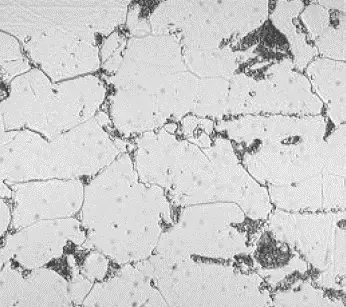

The first picture shows the unaffected base metal of a carbon steel having pearlite and ferrite microstructure.

When this material is exposed to a high temperature above 800-degree Fahrenheit, the graphitization takes place as visible by the black area in the second picture.

Watch this YouTube video for full classroom training on API 571 Damage Mechanism- Graphitization.

Which materials are being affected by the Graphitization

It happens in certain grades of Carbon steel or C S material

and 0.5 Molybdenum steels such as S A 182 F 1 grade and S A 204 grade A, B, and C, etc.

Critical Factors for the Graphitization

The primary factors that affect graphitization are:

- Chemistry of base metal

- Stress, temperature, and time exposure

It Affects Carbon steel and carbon molybdenum steels up to 1.0% Moly. The addition of 0.7% chromium effectively eliminates the graphitization effect in steel.

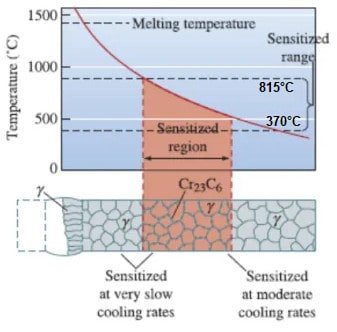

Temperature is being the primary factor controlling the rate of graphitization. Below 800 degrees Fahrenheit ( or 427 degrees Celsius), the rate is extremely slow. A rise in temperature increases the rate of graphitization.

Types of the graphitization

The graphitization is divided into two parts.

The first one is random graphitization.

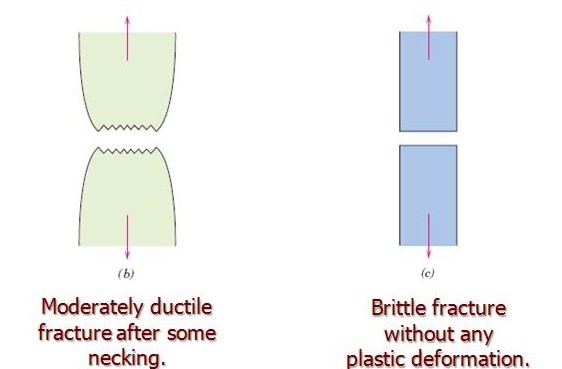

Second, Chains or local planes of Concentrated Graphitization. This type of graphitization can result in a major decrease in load-bearing capability.

Same time, it will be more prone to brittle fracture along this plane.

Chains or local planes of concentrated graphite nodules can be further classified into:

- Weld heat affected zone (HAZ) graphitization, also called EYEBROW graphitization. This is most frequently found in the heat-affected zone adjacent to welds in a narrow band, corresponding to the low temperature edge of the heat affected zone.

- Such zones overlay each other in case of layered multi-pass butt weld and cover whole cross-section. Some conditions such as low temperature area of these HAZ, graphite nodules can form that will result in a band of weak graphite in this area known as eyebrow graphitization.

- Non-weld graphitization, a form of localized graphitization which also occurs in chain-like form. It sometimes occurs along planes of localized yielding in steel. in a chain-like manner it experienced significant plastic deformation as a result of cold working operations or bending.

Timeline for occurrences of Graphitization

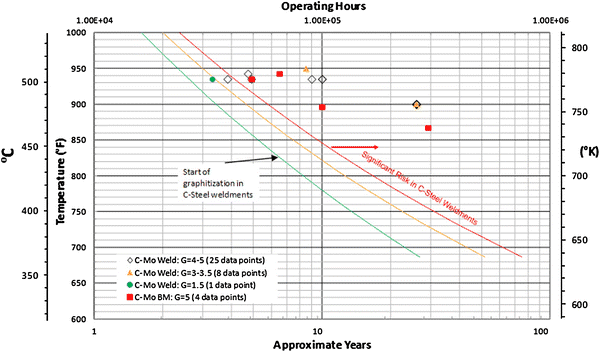

Time-period for graphitization occurrence depends on the material temperature. It can form to severe HAZ graphitization in a short span of five years at a temperature of 1000°F (538°C).

The level of graphitization will not increase much in further service at 850°F (454°C), let us say after 35 years.

The graph here shows the relationship of various heat-affected zone graphitization with service temperature and service hours.

Affected Units or Equipment’s in Refinery

- In FCC- hot-wall piping & related equipment’s, Coker Unit & catalytic reforming units.

- FCCU (Fluid catalytic cracking units) Reactors and piping, CS furnace tubes in a thermal cracking unit.in FCCU- failure of seal welds at the bottom tube sheet of a vertical waste heat boiler.

- Equipment’s operating in the temperature range of 850°F to 1025°F (441°C to 552°C) such as Economizer tubing, steam piping & other equipment.

Appearance or Morphology of Damage

As graphitization damage occurs at the microstructure level, it requires a microscope for observation.

Advanced stages of damage related to lose in creep strength may include micro-fissuring/micro-void formation, subsurface cracking, or surface-connected cracking.

Prevention / Mitigation of Graphitization

Graphitization can be eliminated with the use of low alloy steels having chromium for long-term operating service above 427°C (800°F).

Inspection and Monitoring

- Metallographic testing is mainly used to verify the presence of Graphitization in material. A full section sample is cut and tested by metallography examination. Graphitization occurred within the material thickness is not possible to check by field replicas or in-situ metallography.

- Damaged that has reached in the advance stage as a result of strength loss for example surface breaking cracking and creep could be difficult to locate.