Introduction to 1100 Series Aluminum

Aluminum Alloy of 1100 Series belongs to pure aluminum having very good ductility, moderate strength, general-purpose alloy.

1100 alloy offers high corrosion resistance, good ductility compare to other grades, and high reflective finish, and of course economical too compare to other alloyed aluminum grades such as 4XXX, 5XXX, or 6XXX series. The alloy is having good forming properties making it ideal for forming works jobs.

The aluminum alloy of 1100 is made up of 99% aluminum and 1% of copper, silicon & iron. This alloy has a relatively low melting point and is commonly used in food and beverage cans.

It also has good forming properties, making it ideal for applications that require bending or shaping. 1100 alloy is corrosion resistant and has a high strength-to-weight ratio, making it a popular choice for transportation applications.

1100 series do not heat treatable type of aluminum alloy. The density of this material is 2.71 gm/cm3 and the melting temperature is 643 – 657°C.

Material Specification

AMS: 4001

ASTM: B 209

SAE AMS QQ: A-250/1

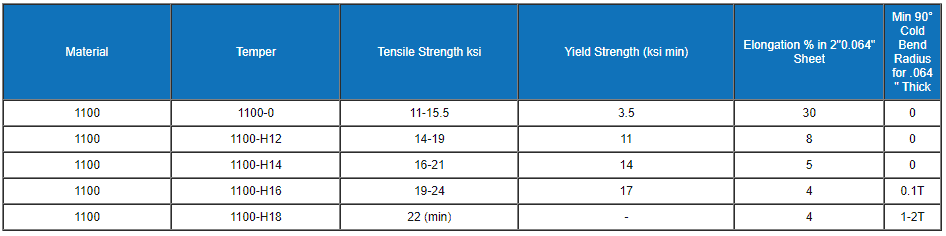

Chemical and mechanical properties

Chemical properties of Al 1100

| Weight% | Aluminum | Copper | Silicon + Iron | Manganese | Zinc | Others |

| 1100 | Remainders | 0,05 – 0,020 | 0,95 max | 0,05 max | 0,10 max | 0,05 (each) 0,15 (total) |

Welding of 1100 Series Aluminum

First, make sure your welding equipment is in good condition and calibrated properly. Next, set the welder to its lowest possible setting.

Then, use a steady hand and make short welds, being careful not to overheat the metal. Finally, always clean and degrease the weld joint before welding.

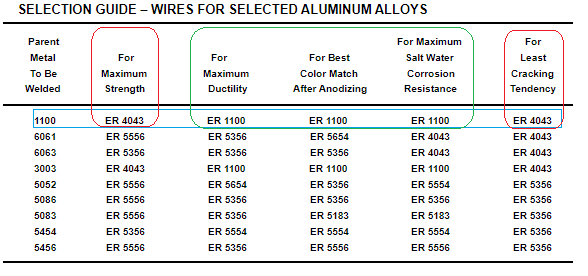

The welding of Aluminum 1100 alloy can be carried out using:

- ER4043

- ER1100

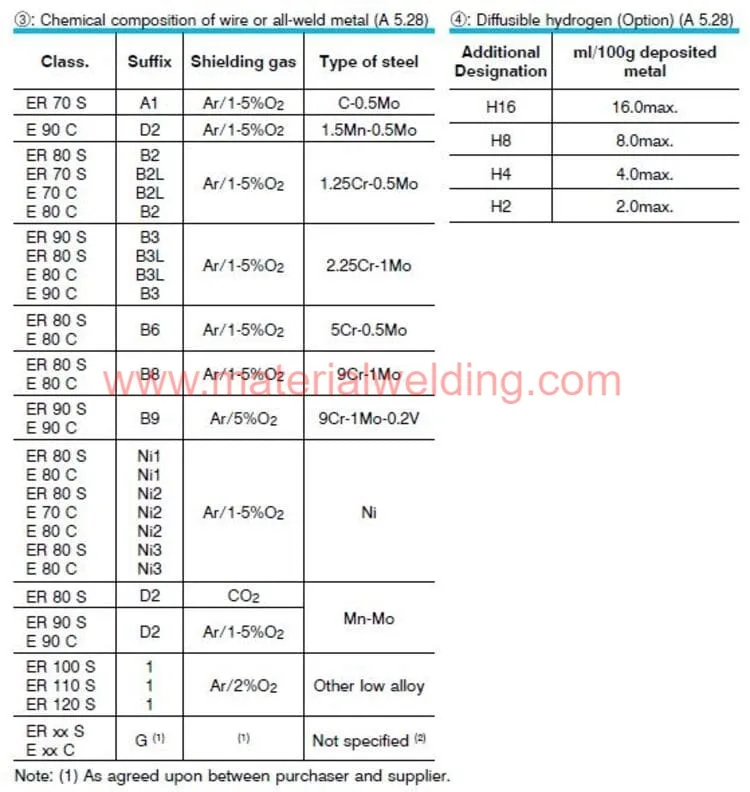

The below table shows the filler wire types for various aluminum grades including the 1100 series. ER4043 shall be used when need maximum strength for 1100 alloy welding.

ER1100 shall be used for welding alloy 1100 aluminum when maximum ductility, saltwater corrosion resistance, and color match after anodizing is required.

Preheat and interpass during welding

Maximum preheat and interpass temperature of 120ºC shall be used for aluminum welding of Alloy 1100, 3XXX, 4XXX, 5XXX series.

Click here to read the Full Aluminum Welding guide.

Shielding/ Purging/ Backing gas for Aluminum welding

Pure Argon is widely used. Argon-Helium mixture in MIG welding. Helium addition helps for a better weld formation and increases the welding speed.

Helium also minimizes the risk of pores and lack of fusion. Pure helium is not used due to the high Ionisation potential of the gas as well as the high cost of the gas.

Welding parameters for TIG/ MIG welding of Al1100

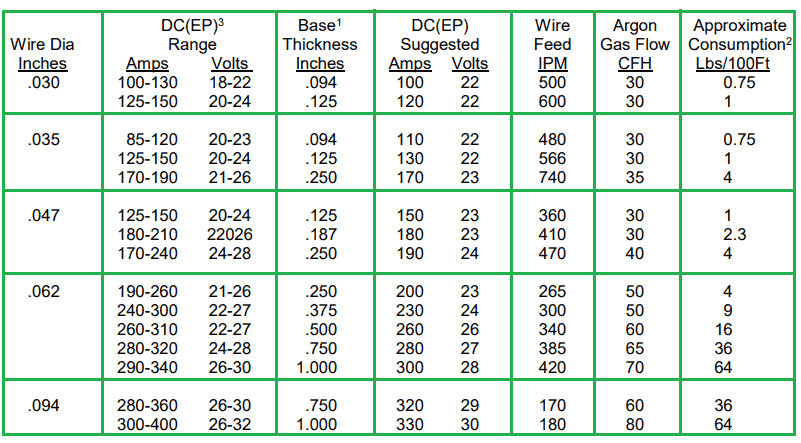

The selection of welding parameters for aluminum welding depends on wire diameter and material thickness.

When welding with 0.030-inch wire diameter, an ampere range of 100-130 amp is used for thickness up to 0.125 inches for aluminum material.

Refer to the below table for detailed welding parameters such as current, voltage, wire feed speed, and shielding gas flow rate.

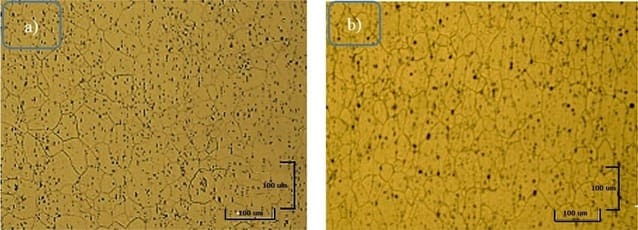

Microstructure of Al1100 material