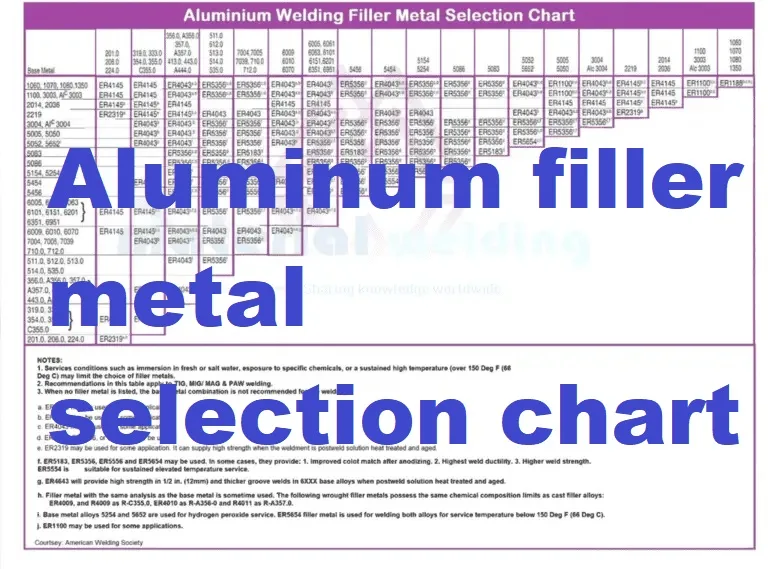

Welding aluminum can be a challenging task, but selecting the right filler metal can make all the difference. With so many options available, it can be overwhelming to choose the appropriate filler metal for the job.

That’s where an aluminum filler metal selection chart comes in handy.

In this article, we will introduce an aluminum filler metal selection chart that simplifies the process of selecting the right filler metal for welding aluminum, helping you achieve a strong and reliable weld.

Aluminum filler metal selection chart

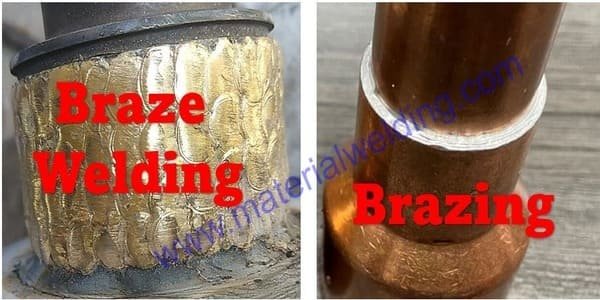

In terms of joining processes, aluminum and its alloys can be joined with a variety of techniques, such as welding, soldering & brazing, adhesive bonding, and mechanical fastening.

Welding, in particular, is the most commonly used joining process for aluminum.

There are several welding processes available for joining aluminum and its alloy assemblies, such as arc welding, stud welding, electron beam welding, laser beam welding, resistance welding, solid-state welding, and oxyfuel gas welding.

However, among these processes, arc welding is the most extensively used, with TIG and MIG welding being the most common.

Click here to see & Download large-size image.

| Aluminum Grade | Welding Wire |

|---|---|

| 1060, 1100 | ER1100 |

| 2014, 2036 | ER4043, ER5356 |

| 2216 | ER4145 |

| 3003 | ER4043, ER1100 |

| 5052, 5652 | ER5356 |

| 5454, 5086 | ER5356 |

| 6061 | ER4043, ER5356 |

| 6063 | ER4043, ER5356 |

| 7075 | ER4043 |

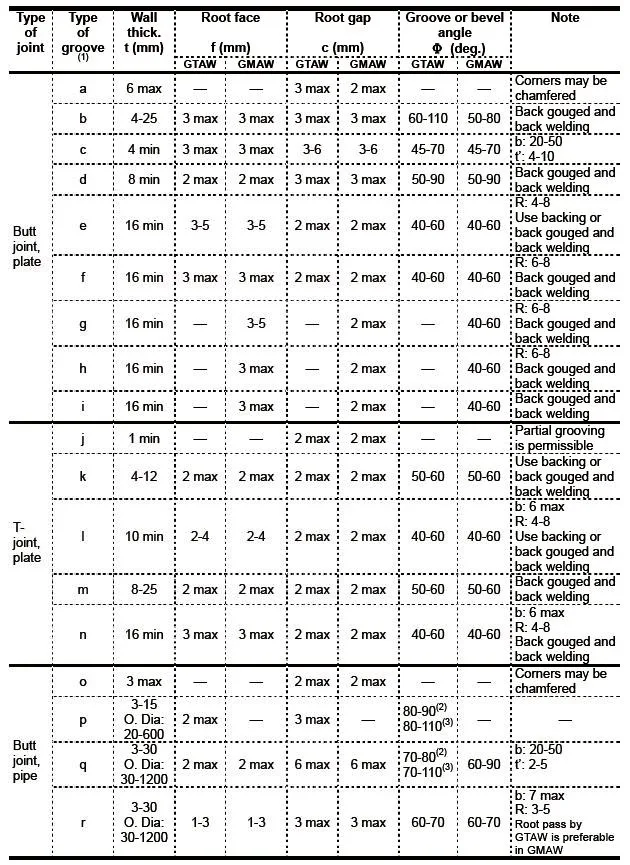

Groove Design Chart for Aluminum Welding

Related Reading:

- How to Select Right Welding Rod for your job?

- Click here to download Welding electrode selection chart pdf pdf

Welding aluminum is a popular method for joining parts in various industries, but it requires a proper groove design to ensure a successful weld.

The groove design refers to the shape and size of the gap between the parts to be joined.

Using the correct groove design for the specific joint configuration and thickness of the aluminum parts is essential for achieving a strong and reliable weld.

A groove design chart for aluminum welding is a helpful tool that simplifies the groove design process by providing a comprehensive list of groove shapes and dimensions.

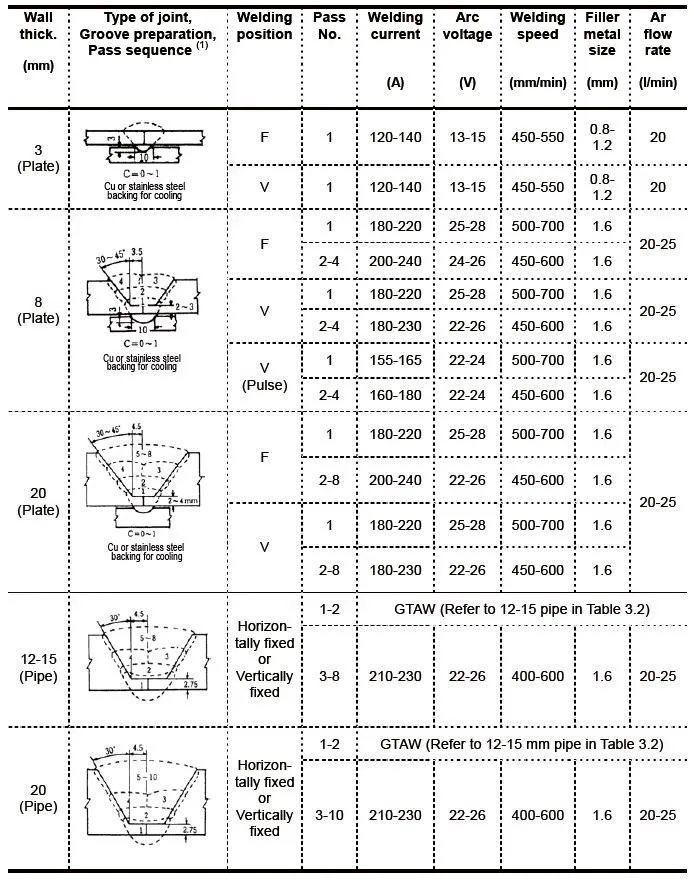

Below is a groove design chart for aluminum welding and discuss how to use it to select the appropriate groove design for a given joint configuration and aluminum thickness.

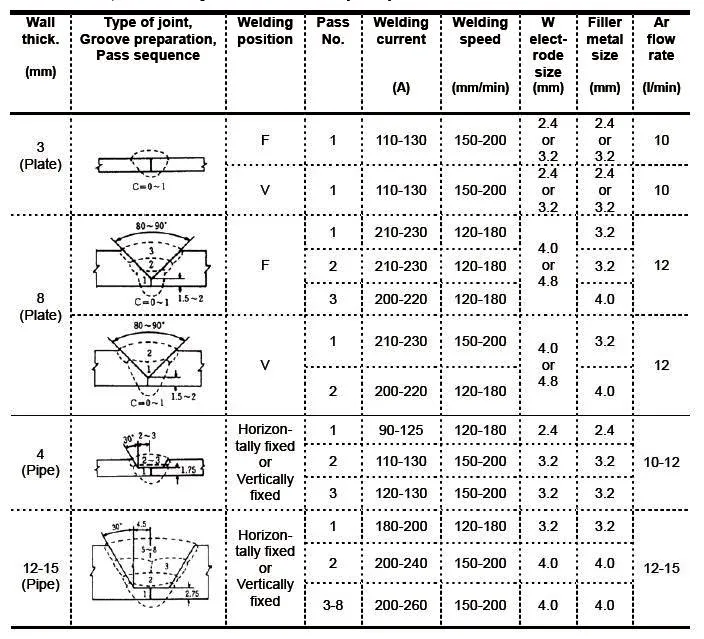

TIG welding Parameters Chart for Aluminum Welding

Tungsten inert gas (TIG) welding is a popular method for welding aluminum due to its versatility and ability to produce high-quality welds.

Although, TIG welding requires precise control of various welding parameters to achieve optimal results. Welding parameters such as current, voltage, welding speed, and gas flow rate are critical factors that must be carefully controlled to ensure a successful weld.

To simplify the TIG welding process for aluminum, a TIG welding parameters chart is a useful tool that provides a comprehensive list of recommended welding parameters for different aluminum thicknesses and joint configurations.

MIG welding Parameters Chart for Aluminum Welding

Metal inert gas (MIG) welding is a popular method for welding aluminum due to its speed and ease of use.

However, MIG welding also requires precise control of various welding parameters to produce high-quality welds. Welding parameters such as wire feed speed, voltage, and gas flow rate are critical factors that must be carefully controlled to ensure a successful weld.

To simplify the MIG welding process for aluminum, a MIG welding parameters chart is a helpful tool that provides a comprehensive list of recommended welding parameters for different aluminum thicknesses and joint configurations.