Can you weld 6061 aluminum

Can you weld 6061 aluminum: The short answer is Yes. 6061 aluminum is a popular choice for welding jobs because it can be easily melted and welded together when using right welding parameters.

However, you need to be careful when welding 6061 aluminum because if the weld is not done properly, the metal can crack, cause welding porosity and fail due to poor weld quality.

Is 6061 aluminum weldable?

Yes, 6061 aluminum is definitely weldable. In fact, it’s one of the most popular alloys for welding. 6061 aluminum is a heat-treatable grade widely used in the transportation and structural applications.

Though it is not as strong as some other 5000 series alloys, it has good corrosion resistance and formability, making it ideal for welding. With its low melting point, 6061 can be easily welded using any standard method, including MIG, TIG, and arc welding.

Read more: How to Stick Weld Aluminum?

6061 Weldability

6061 is a heat treatable 6000 series aluminum alloy having Silicon & Magnesium as primary alloying elements. It has good weldability and can be welded with all common welding method. The UNS Number for 6061 is A96061 & Welding P Number is P23.

Other alloying elements include iron, copper, chromium, titanium and zinc. 6061 aluminum has good ductility and can be cold worked.

The main physical properties of 6061 alloy are:

| Physical Property | Value |

|---|---|

| Density | 2.70 g/cm³ |

| Melting Point | 650 °C |

| Thermal Expansion | 23.4 x10^-6 /K |

6061 aluminum can be welded using all of the common welding methods (TIG, MIG, arc, plasma and laser).

However, it is important to note that 6061 should not be joined using oxy-acetylene welding.

When welding 6061 aluminum, it is important to use a filler metal that has good corrosion resistance and is compatible with the base metal.

Some good choices for filler metals include ER4043 TIG MIG Welding Wire rod and ER5356.

Related reading: Aluminum Welding Guide

6061 Aluminum welding Tips

Here are some tips to help you weld 6061 aluminum:

- Use a clean, well-ventilated area when welding with humidity control especially when welding with MIG welding. High humidity will cause weld porosity.

- Make sure that your welding equipment is in good condition and that the electrode is the correct size for the job.

- Use a high current setting when welding 6061 aluminum. Choose right welding polarity– DCEN or Pulse for TIG and AC or Pulse for MIG Welding.

- Practice your welding technique on scrap pieces of aluminum before starting your project. This will help you get a feel for how the metal behaves and how best to weld it.

Related Reading: How to remove oxidation from aluminum?

Best filler rod for 6061 aluminum

There are many types of filler rod that can be used for 6061 aluminum. The best type of filler rod to use for this metal is the 4043 rod.

This is because it has a lower melting point than the other types of rod, and it is also less likely to cause porosity in the weld.

The next best type of filler rod to use for 6061 aluminum would be the 5356 rod. This type of filler rod has a higher melting point & weld strength than the 4043.

TIG Welding 6061 aluminum filler rod

If you’re planning on TIG welding 6061 aluminum, you have two main filler rod choices: ER4043 and ER5356.

Both have their pros and cons, so it’s important to know which one is best for your project.

ER4043 is a good all-purpose filler rod with good crack resistant features. It can be used for welding both thin and thick materials, and it produces good looking welds.

However, the welds made with ER4043 has low strength, ductility and poor color match compared to ER5356.

ER5356 filler rod is also the best choice for TIG welding 6061 aluminum. ER5356 gives high strength weld with good ductility and color match.

However, it doesn’t flow as smoothly as ER5356 and can be more difficult to control.

MIG Welding 6061 aluminum

MIG welding 6061 aluminum can be done with either 100% argon or a 75/25 mix of argon and helium.

It is important to use a pure gas (free from moisture & impurities) when welding this particular alloy because it helps to prevent porosity.

MIG Welding 6061 aluminum can be done with two types of welding wire: ER4043 and ER5356. Here are some tips on how to weld this metal effectively.

Related Reading: Proven Tips and Tricks For Mig Welding Aluminum

When MIG welding 6061 aluminum, it’s important to use the right type of welding wire.

ER4043 is a good choice for welding this metal, as it has good corrosion resistance and can be used on a variety of thicknesses. ER5356 is another option that can be used for welding 6061 aluminum.

This type of wire has a higher melting point, which makes it ideal for thicker metals.

To get the best results when MIG welding 6061 aluminum, it’s important to use the right settings on your welder including setting right amperage, polarity and material surface preparation.

The wire feed speed and voltage should be set according to the manufacturer’s instructions.

6061 filler rod

There are a variety of filler rods available on the market for the TIG welding of aluminum.

For example, ER4043 and ER5356 are popular choices for the 6061 alloy. However, which one is the best choice for your application?

ER4043 is a general purpose TIG welding rod that can be used on a variety of aluminum alloys.

It is considered to be an all-purpose rod, as it can be used for both light and heavy gauge work. Additionally, it provides good penetration and has a low melting point.

ER5356 is also a good choice for TIG welding 6061 aluminum. This rod has a higher melting point than ER4043, which makes it ideal for heavier gauge work. Additionally, it provides good weld strength and corrosion resistance.

So, which filler rod should you choose for your 6061 aluminum?

Can aluminum be welded?

Yes, aluminum can be welded, but it is not as easy to weld as other metals.

Aluminum has a lower melting point than other metals, so it is important to use a welding rod that has a lower melting point as well.

Aluminum also oxidizes quickly, so it is important to clean the metal before welding.

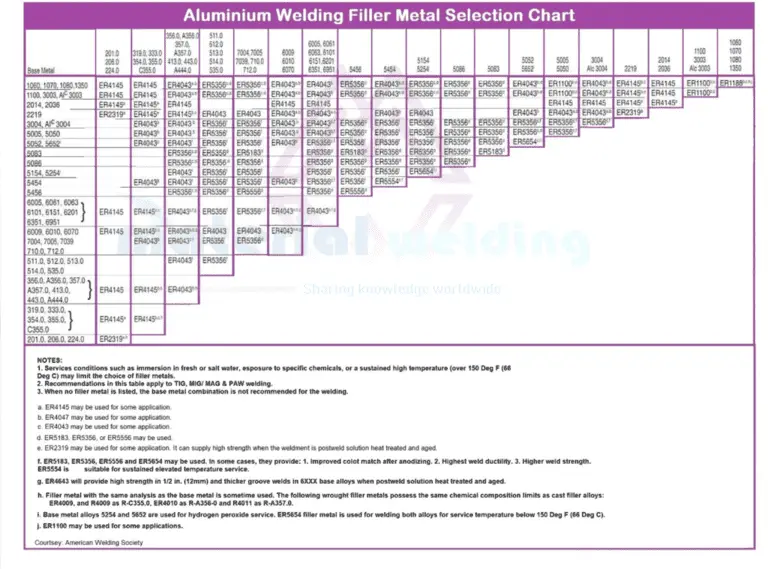

Aluminum weldability chart

Aluminum is a versatile metal that can be used for a variety of welding projects.

However, it’s important to know which type of aluminum is best for your job. This aluminum weldability chart will help you choose the right type of aluminum for your welding work.

Click here to see large size image.

What filler rod for 6061 aluminum?

6061 aluminum is a versatile material that can be welded using a variety of different filler materials. In most cases, a 4043 or 5356 filler rod will be the best choice for welding 6061 aluminum.

However, depending on the thickness of the material and the desired final results, other filler materials may also be used. Aluminum weldability chart given above is very helpful to choose the right filler wire for any aluminum grade material.

Related Reading: Aluminum Welding Rods-How to Choose the Right One

6061 aluminum welding wire

6061 aluminum is a versatile material that can be used for a variety of applications.

When it comes to welding, two common types of welding wire that are used for this metal are ER4043 and ER5356.

ER4043 is a general-purpose type of welding wire that is often used for 6061 aluminum.

It is a good choice for welding in all positions and produces excellent results on both thin and thick materials.

ER5356 is another common type of welding wire that can be used for 6061 aluminum.

This wire produces strong welds that are resistant to corrosion. It is often used in applications where the finished product will be exposed to harsh conditions or extreme temperatures.

Is 6063 aluminum weldable?

6063 aluminum is a popular alloy that is often used in the construction industry. It is known for its strength and durability. But what about weldability? Is 6063 aluminum weldable?

Yes, 6063 aluminum is weldable. In fact, it is one of the most easily welded alloys. The main thing to keep in mind when welding 6063 aluminum is to use a filler alloy that has a lower melting point than the base metal. This will help to prevent the formation of cracks.

The best welding filler wire rod for 6063 aluminum is ER4043. This wire gives crack resistant welding for 6063 aluminum.

6063 aluminum weldability

6063 aluminum is widely used in the construction industry because of its high strength and weldability.

However, 6063 aluminum welding can be tricky because of its low melting point. Here are some tips for successfully welding 6063 aluminum:

- Use a welding rod with a low melting point such as ER4043 TIG-MIG filler wire rod.

- Preheat the metal before beginning to weld when welding thick aluminum. This is due to high thermal conductivity of this alloy.

- Weld slowly and evenly to avoid overheating the metal.