Weld Repair for Cracked Aluminum Wheel: Should You Make the Fix?

Welding is a common repair method for cracked aluminum wheels. However, there are some risks associated with welding aluminum rim or wheels. The quality of the weld is very important, as is the safety of the vehicle & driver &/or passengers.

There are a few things to consider before making a decision. First, the size and location of the crack will determine if it can be safely repaired. If the crack is large or in a critical structural area, it is best to replace the wheel. However, if the crack is small and in a non-critical area, then welding may be an option.

Continue this post to Learn Step by Step Guide for Aluminum Wheel Welding repair.

If the weld is not of good quality, it can cause the wheel to crack further or even come apart completely. This could lead to serious injury or even death.

Therefore, it is important to make sure that the welder is experienced and has a good reputation.

Another risk of welding aluminum is that it produces fumes that can be harmful to your health. Therefore, it is important to make sure that you are in a well-ventilated area when welding.

Overall, welding aluminum wheels can be a risky proposition. However, if done correctly by an experienced welder, it can be a safe and effective way to repair cracked aluminum wheels.

Aluminum Wheels: Why Do They Fail?

Aluminum wheels are a popular choice for many car owners because of their durability and aesthetic appeal.

However, aluminum wheels can fail and cause serious damage to your car. There are several reasons why aluminum wheels fail, including:

- Lack of maintenance: Aluminum wheels need to be regularly cleaned and polished to maintain their finish. If they are not properly maintained, the metal can start to corrode and flake off, eventually leading to wheel failure.

- Harsh weather conditions: Extreme heat or cold can cause the metal in aluminum wheels to become brittle and crack. This is especially true if the wheels are not properly protected with a clear coat or sealant.

- Curbing: Hitting a curb can damage the structure of an aluminum wheel, causing it to warp or crack. This type of damage is often irreparable and can lead to wheel failure.

Did you hit a pothole or road barrier & got your Car or SUV wheel cracked? Instead of buying a new one, you might be wondering about the integrity & assurance of welding quality of your Wheel.

Repairing a cast aluminum Wheel or Rim of a vehicle is a matter of safety for yourself and your family who might use it.

Why you need to weld Cracked Aluminum Wheel?

If you have a cracked aluminum wheel, you may be wondering if you need to weld it. The answer is yes! Here are three reasons why you need to weld your cracked aluminum wheel:

- Welding will make the wheel stronger.

- Welding will help prevent the crack from spreading.

- Welding will give the wheel a new lease on life.

If you have a cracked aluminum wheel, don’t hesitate to weld it. It’s the best way to ensure that your wheel is strong and durable.

If you notice crack in the wheel, you have two options:

- Discard the cracked wheel and replace with a new Wheel.

- Perform a Welding of Wheels. In this case, you must ensure a sound weld quality.

So, the weld repair must be very high quality, sound weld, and strong enough to provide safety & integrity to the Wheel.

A cracked Wheel/rim can be fatal, assume a car at very high speed and the wheel fails, and the results will be putting lives in danger.

Also, any crack or damage to the wheel/ rim will lead to an air leak from the tire. such issues require immediate attention to rectify the problem.

So, Should you repair the Rim or replace it with a new one?

Well, honestly- as long as you can make sure what is the grade of cast aluminum Wheel & choose suitable matching welding consumables, you are good to go with a Wheel Welding repair.

Making a welding crack repair using matching welding filler wire on a cracked wheel, without any welding imperfection/ defects and welding of high quality are the essential tasks, we are looking at to ensure that the repaired wheel welding or rim welding is fit to use for the intended service & application.

First, which welding process is best for repair?

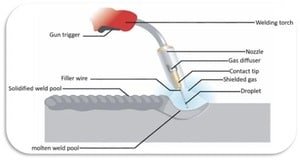

To be precise and cut the long story short- I will recommend using only Gas Tungsten Arc Welding (GTAW) or also called TIG welding.

The obvious reason is- that TIG produces weld joints of very high quality and highly clean welds although very slow welding process.

But, finally what matters is the welding quality in critical weld repairs. TIG welding of cast aluminum with pure argon as shielding & purging gas suits best for the welding Wheel or Rim Crack or any other repair type.

TIG Welding Rod for cast aluminum rim or wheel repair

In the USA, Canada, Europe, and Japan AlSi7Mg0.3 are used mainly as the cast aluminum alloy material.

ER5356 TIG wire is best suited for welding these grades as well as many other cast aluminum & forged aluminum rim grades used for the rim & wheel making.

Always use a reputed manufacturer welding wire to ensure good quality & alloying are present within the standard limit in the welding filler wire.

ER5356 filler wire in spool form can be used for the MIG welding of cast aluminum Wheel/ Rim repair.

Steps for repairing the crack in cast rim

- The first and most important step before you commence the welding wheel repair work is to identify the crack by its origin point and endpoint.

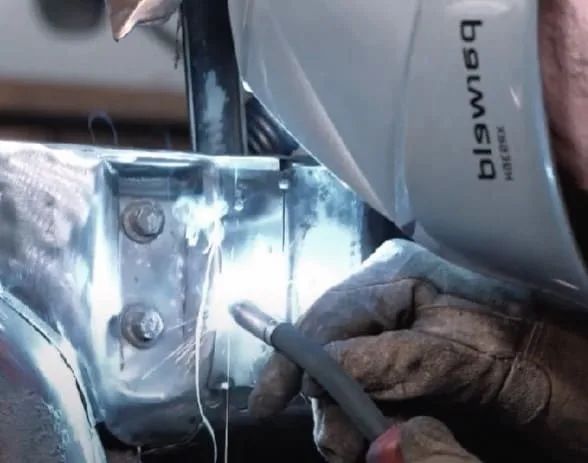

- Next, arrest the crack by drilling small-diameter holes (let’s say around 4 to 5 mm- 1/6 inch) at these points so the crack will not propagate further due to grinding or any hammering stresses as shown in the below picture.

2. Next, prepare a wider groove in the crack area, so the weld can be deposited onto it. Use a grinding wheel to grind it.

Be careful to use gloves as aluminum can get hot without any change in color. so you will not know if it’s hot to touch or not unless u touch it with your bare hands.

3. Once the welding groove is prepared and the existing crack is fully removed, you are ready to deposit the silver color.

Use AC TIG Welding, with current set up according to the filler wire diameter. Click here to find guide on choosing weld parameters. Make sure to fuse the weld fully with the cast Aluminum Wheel/ rim material.

4. Follow the same procedure to weld on the other side of the wheel. Do not leave any underfill area as it can cause issues with the tire fitment later on.

Complete the weld on the other side of the rim using the same filler wire & welding settings.

5. Next step is very critical as you need to match the rim surface by grinding the extruded welding area.

Use, good quality and 200 Grit size emery paper to make a rough finish at first followed by 400 Grit size emery paper to provide a good quality surface finish.

This will ensure that there is a smooth transition between the welding repair area and the original rim material that will allow the right fitting and alignment of the wheel on the rim and there will be not any air leak during the use.

6. Carry out Liquid Penetrant Testing (LPT) to ensure weld quality is very high. If you notice any imperfections, you can repair them for sound weld quality and long life of the welding repair.

In all these tasks, welder skills are very important as welders need to be proactive & innovative.

The actual cracks in the cast material can be of different shapes and dimensions and it might require changes in the repair procedure. A welder with good repair skills will be able to modify his approach to suit the needs.

Conclusion

In conclusion, wheel welding repairs are much cheaper than replacing the wheel entirely.

However, it is important to only use a TIG welder for high-quality repairs. While replacing the wheel is costly, it may be necessary if the repair is not done correctly.