What is Repair Welding?

Welding repair is the process of repairing a weld. This can be done for a number of reasons, including fixing a defect in the weld, improving the weld’s strength and/or appearance, or restoring the weld to its original condition (e.g. repair of in-service defects).

There are a number of different welding repair techniques, each with its own advantages and disadvantages. Some common techniques include removing the defect & re-welding, welding a patch, and in-kind replacement of the affected part.

There are several benefits to welding repair:

- It is quick and easy,

- It restores the metal to its original strength, and

- It is less expensive than a replacement.

Procedure for welding repair

Welding repairs based on the requirements, location, and service, are classified as the following types:

1. Production weld repair

2. In-service weld repair

Why you need to perform the repair, could be due to an inherent material defect, a process defect during/ after welding (manufacturing defects), or in-service failure.

A well-written welding repair procedure or method statement involves defect identification, location marking, removal of weld defects, verification for a successful repair, and proper documentation for future repair tracing.

Sample Welding repair procedure.pdf

Factors to be considered before starting the welding repair?

Before commencing the welding repairs, various aspects such as material type, repair location, equipment’s availability, and more as listed below need to be reviewed & considered.

Related Reading: Welding Electrode/ Filler wire/ Filler metal Selection Chart

Out of these factors, the financial part is most considered in various aspects. Such as, whether the repair is worth performing or not.

Before making a final decision, the following aspects need to be considered & answered by the fabricator to perform the welding repair:

• Is it possible to achieve structural integrity by repair?

• Any other alternatives to planned repair?

• What was the root cause of the earlier defect and can it happen again?

• Defect removal technique and process & its effectiveness?

• NDT method to ensure defect elimination with the above processes.

• Do you need prior in-principle approval for the Repair statement from the customer?

• Does adequate consideration is given to anticipated welding distortion that can affect the repair integrity?

• Any requirements for heat treatment after repair?

• NDT method for repair verification?

Steps for the welding repair?

The weld repair might seem easy and handy work but it all depends on the type of repair and its criticality.

For a successful and effective weld repair, for example- a production weld repair requires the involvement of the production, QC Department, NDT, Design, and Welding engineering department as teamwork.

And similarly, an in-service repair in a running plant requires efforts of plant engineering, reliability, and engineering people. A pre-study to find the root cause of the existing repair is very helpful to mitigate its occurrence and applying preventive measures in the repair procedure by the relevant department.

In a general scenario, a repair task follows these steps:

• A pre-study for existing defect (flaw) & it’s severity. This is done by visual inspection and applying other NDT techniques.

• Prepare the area for visual inspection that will aid in a successful & effective inspection.

• Identify the start, endpoint, and current location of the flaw for repair.

• Method of defect removal (e.g. by machining or grinding or gouging).

• Non-Destructive Testing to verify the complete elimination of the flaw.

• Use of approved Welding procedure to perform the welding repair.

• Use of qualified welders.

• Final weld cleaning and visual inspection.

• Application of appropriate NDT method for verification of new weld after repair.

• Any PWHT after repair such as in case Cr-Mo alloys repair.

• Final NDT after complete PWHT & any hold time if applicable.

Production repairs, Analysis & Assessment

Repairs are usually identified during production inspection. Evaluation of the reports is carried out by the Welding Inspector, or NDT operator.

Discontinuities in the welds are only classed as Welding Defects when they are outside the range permitted by the applied code or standard. Before the repair can commence, a number of elements are required to be fulfilled.

Analysis

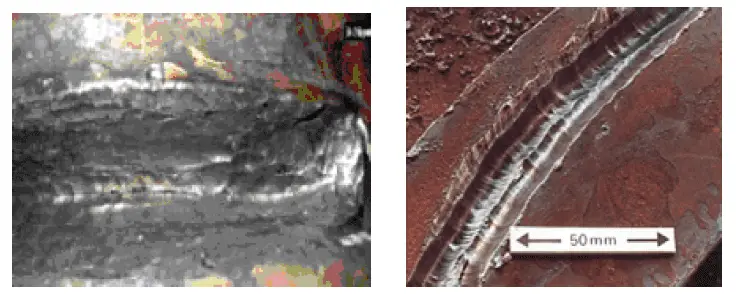

As this defect is surface-breaking and has occurred at the fusion face the problem could be cracking or lack of sidewall fusion.

If the defect is found to be cracking the cause may be associated with the material or the welding procedure, however, if the defect is lack sidewall fusion this can be apportioned to the lack of skill of the welder.

Assessment

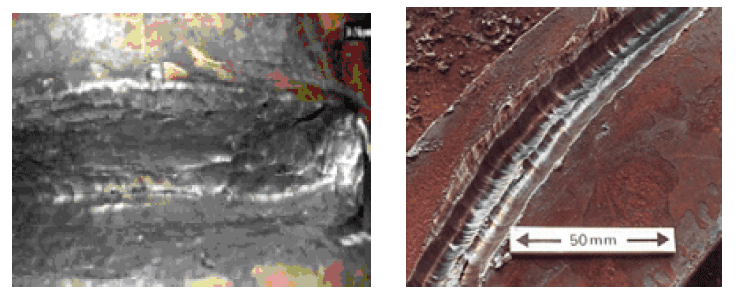

In this particular case, as the defect is open to the surface, magnetic particle inspection (MPI) or dye penetrant inspection (DPI) may be used to gauge the length of the defect, and ultrasonic testing (UT) is used to gauge the depth.

A typical defect is shown below:

Excavation/ Removal of welding defect:

If a thermal method of excavation is being used i.e. arc/air gouging it may be a requirement to qualify a procedure as the heat generated may have an effect on the metallurgical structure, resulting in the risk of cracking in the weld or parent material.

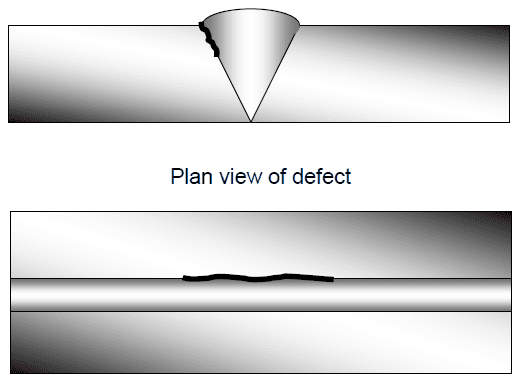

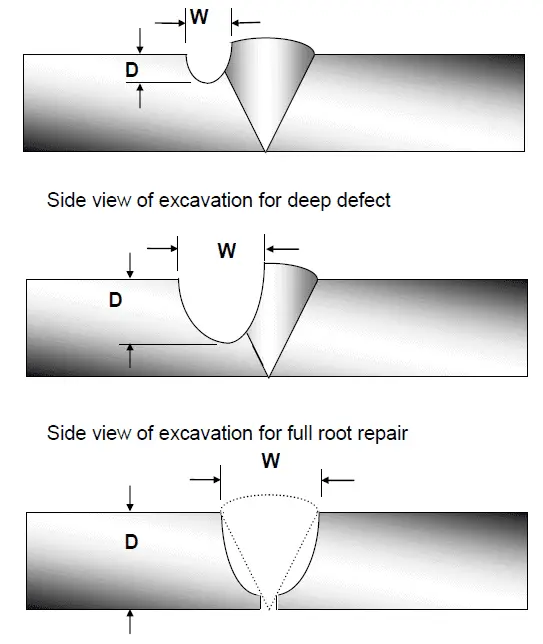

To prevent cracking it may be necessary to apply a preheat. The depth to width ratio shall not be less than 1 (depth) to 1 (width), ideally, 1 (depth) to 1.5 (width) would be recommended (ratio: depth 1 to width 1.5).

A side view of excavation for a slight sub-surface defect is given below:

Cleaning of the Excavation & confirmation of defect removal

At this stage grinding of the repair, the area is important, due to the risk of carbon becoming impregnated into the weld metal/parent material.

It should be ground back typically 3 to 4mm to bright metal. At this stage, NDT should be used to confirm that the defect has been completely excavated from the area. Usually, Penetrant testing & magnetic particle testing are the NDT method used for this purpose.

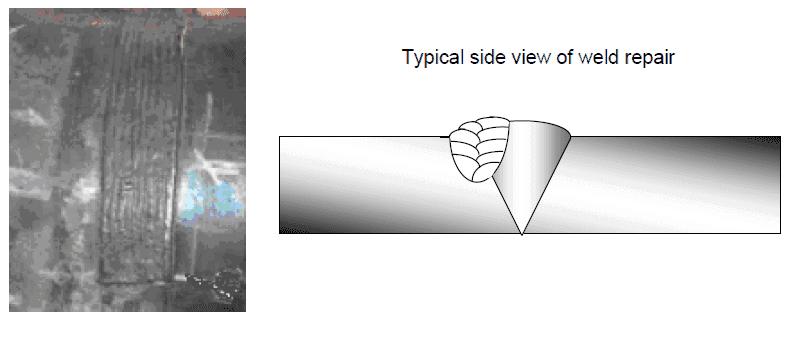

Re-welding of the welding defect area:

Prior to re-welding of the excavation, a detailed repair welding procedure/ method statement shall be approved.

Click here to download General-repair-procedure-for-welds You can modify it to suit your requirements.

NDT confirmation of successful repair

After the excavation has been filled the weldment should then undergo a complete retest using the same NDT techniques as previously used to establish the original repair.

This is carried out to ensure no further defects have been introduced by the repair welding process. NDT may also need to be further applied after any additional post-weld heat treatment has been carried out.

Types of Weld Repairs

Weld repair is a common practice in the welding industry. There are several types of weld repair that can be used, depending on the situation. There are many types of weld repairs that can be made, but the most common are:

- Spot Welds,

- Stitch Welds, and

- Plug Welds.

Spot welds are used to join two pieces of metal together by making a series of small welds in a row. This is the most common type of weld repair and is often used to fix damaged or cracked metal.

Stitch welds are similar to spot welds, but they are used to join two pieces of metal together in a zigzag pattern. This type of weld repair is often used to fix large tears or holes in metal.

Plug welds are used to fill in large holes in metal by welding a plug of metal into the hole.