Casting repair, a work of patience.

Cast Iron has different types and only some have limited weldability while others are not weldable at all such as white cast iron. Using a correct approach, suitable welding technology, and correct welding electrode, a cast iron repair can be mastered.

In this post, a detailed step-by-step welding repair guideline for repairing a Gearbox casting is explained.

Click here to Get a Guide on How to Weld various materials

Welding Repair of Cracked Gear Box Casing (Transmission Case)

Steps to commence the Cast Iron Repair:

- First of all, drill holes on both sides of the crack to arrest the crack. This will help to eliminate further propagation of the crack into the material.

- Clean the welding area & surrounding area from any paint, grease, or oil contamination.

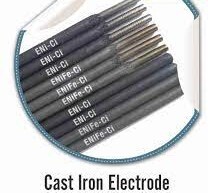

- For welding, I prefer to use the “cold method, or also called cold welding” ENiFe-CI SMAW coated stick welding rods. These rods offer a dissimilar weld deposit with high ductility to withstand the high residual stresses arising in cast iron welding.

- Use very short runs of a maximum 30 mm length also called pilgrim welding, no preheat usually but if needed to remove moisture, preheat to a maximum of 110 Degree Celsius or 225 Degree Fahrenheit.

- Use hammer peening for residual stress relief after each run. This will help to avoid cracking in the weld.

- Follow a maximum of 100 Degree Celsius or 200 Degree Fahrenheit interpass temperature. Alternately, if the temperature measuring device is not available, wait until it’s cold to touch before welding the next run.

- The welding technique will be slow but going to be very fruitful to avoid any cracking in the weld or cast iron HAZ.

- Don’t forget to weld the drilled holes at the end of the welding.

For Aluminum Gear Box (Transmission Case) repair, Click below the post.

Click here to learn various types of cast iron & their identification.

Cold Repair of Cracked Gear Box Casing (Transmission Case)

Gear boxes (Transmission cases) are an important part of a car, and they need to be in good condition to ensure the car runs smoothly. If a gear box is cracked, it can cause problems with the car and needs to be fixed as soon as possible. There are two ways to fix a cracked gear box casing: hot or cold repair.

Hot repair (By welding explained earlier) is when the gear box (Transmission case) is taken apart and then welded back together. This is the more common method, but it can damage the gears in the gear box.

Cold repair is when the gear box (Transmission case) is not taken apart and the cracks are repaired using an epoxy resin. This is a newer method, and it does not damage the gears in the gear box.

Belzona has developed a process for repairing gear box casings using a two-part epoxy resin system. The epoxy resin cures at room temperature to form a tough, durable repair that can withstand the high stress and vibration encountered in gear boxes. The repair can be done in situ, without having to remove the gear box from the vehicle.

JB weld also offers a cold-repair option for gear box casing repairs. JB weld is a two-part epoxy adhesive that cures at room temperature to form a tough, durable bond.

| Image | Product | Details | Get Best Price |

|---|---|---|---|

| JB Weld Original Cold Weld | Setting time: 4- 6 Hours Curing time: 15- 24 Hours Color after curing: Dark Gray Strength: 5020 PSI | Check Price |

| JB Quikweld fast setting | Setting time: 6 minutes Curing time: 4- 6 Hours Color after curing: Dark Gray Strength: 3127 PSI | Check Price |

| JB Weld EXTREMEHEAT Paste | Setting time: 1 Hour Curing time: 24 Hours Color after curing: Dark Gray Temperature limit: Upto 1000°F | Check Price |