Aluminum 2000 properties

2000 Series aluminum is a copper base Aluminum alloy having high strength and hardness with good machinability. Commonly used grades under the 2000 series are Grade 2011, 2014, 2024, 2124, 2219 & 2618A.

2000 series alloys provide high strength when they are heat-treated in right way but their corrosion protection is poor. They are used in the aerospace sector.

Issue of cracking in 2000 series aluminum

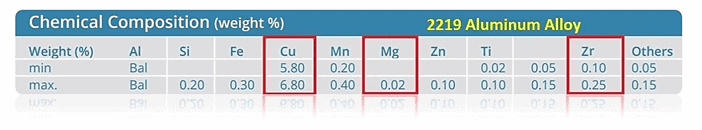

2000 series aluminum alloys typically contain between 2-10% copper (see below tables for 2219 & 2204). Copper addition facilitates precipitation hardening of aluminum to reach strength levels comparable to steel.

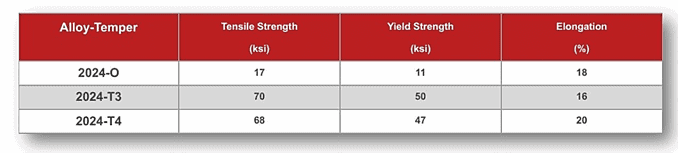

These are heat-treated Al-Cu alloys with tensile & yield strength of up to 70 & 50 Ksi respectively, which is absolutely amazing. But there is one big problem with these alloys; like most precipitation-hardened alloys, they are prone to cracking, especially with arc welding.

Hot Cracking in 2000 aluminum alloys

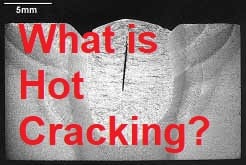

Hot cracking sensitivity (during welding) and stress corrosion cracking tendency (after welding) are the most common problems of welding this group of aluminum alloys such as 2024 and 2219.

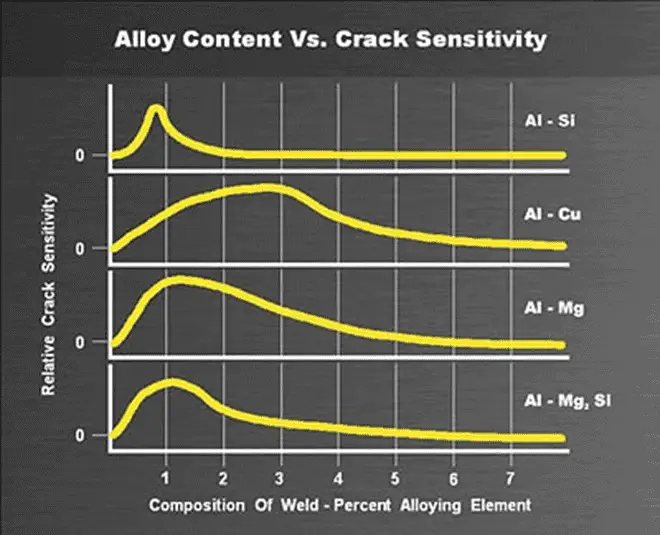

Hot cracking sensitivity of the Al-Cu alloys peaks at around 3% Cu and then, it decreases to a relatively low level at 5% Cu content. Those 2000 alloys with higher Cu-content are considered to be resistant to hot cracking. Alloy 2219 is the most common in this series with 6.3% Cu and 0.2% Zirconium but with no Magnesium addition.

Welding of Alloy 2219

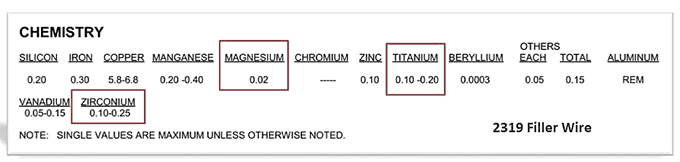

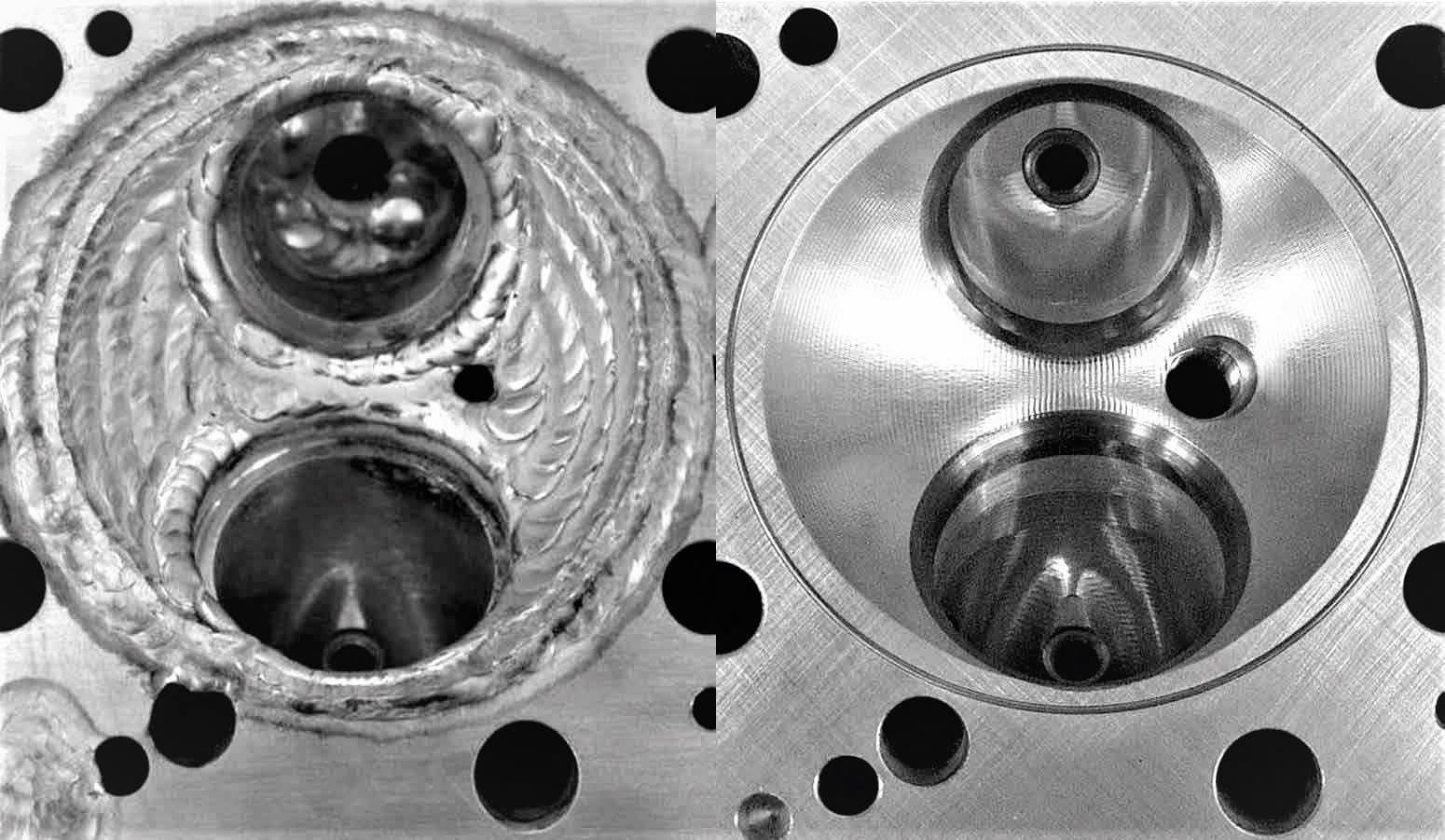

The chemical properties of Alloy 2219 are given in the below table. TIG or MIG Welding of aluminum 2219 is carried out using ER2319 filler wire using pure argon gas for gas shielding. TIG welding is used using DCEN polarity.

As you might have noticed, I underlined “no Mg addition” for describing 2219 alloy. This is important because Magnesium (Mg) causes weldability problems for Al-Cu alloys, even if they are in the safe zone of the crack sensitivity diagram.

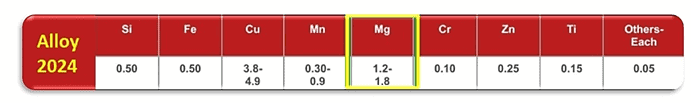

Alloy 2024 is a good example of this; it contains 4.5% Cu and 1.5% of Mg. To put it briefly, magnesium depresses the solidus temperature and widens the “mushy range” or “coherence range” during solidification which causes more segregation at the grain boundaries and increases the susceptibility to both types of cracking (Hot cracking & Stress Corrosion Cracking).

Welding of Alloy 2024

The chemical properties of aluminum 2024 are given in the below table. ER2319 filler wire using TIG or MIG welding is used for welding 2024 aluminum grade. Pure argon is used for shielding purposes. DCEN welding polarity is used in TIG welding of Aluminum 2024.

Using filler metals with very low Mg content is extremely important for welding 2000 series aluminum alloys. In addition to that, zirconium & titanium additions to the filler metal reduce the crack sensitivity of the weld metal (Refer below for chemical composition of ER2319 filler wire).

And, never forget the golden rule of aluminum welding: Always try to keep the welding heat input as low as possible.