Meaning of E6013 Welding Rod

SMAW/ Stick electrode E6013 as per AWS SFA 5.1 or E4313 as per SFA 5.1M or CSA W48 is the most widely used stick welding electrodes for sheet metal, general fabrication & structural welding work.

E6013 (CSA E4313) electrodes are similar to rod-type E6012 (CSA E4312) electrodes but E6013 is having distinct differences in the coating, slag formation & welding polarity.

“E6013 electrodes have a soft arc with low penetrating power, & fast freezing slag. Due to this, there can be a lack of penetration in the fillet weld joint with insufficient root fusion.“

E6013 (CSA E4313) electrodes arc is soft with a weld bead giving smooth weld ripples with a good appearance. E6013 welding rod welding usability characteristics can vary between different rod manufacturers.

They can be used effectively for welding of sheet metal, galvanized steel, and in the vertical uphill or overhead positions (Overhead welding Tips & Tricks) due to their limited penetrating ability.

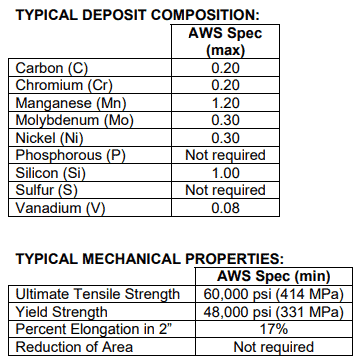

Chemical and mechanical properties of E6013 Rod

The chemical & mechanical properties of the E6013 stick welding rod are given in the below table. The tensile strength of the E6013 rod is 60 ksi (414 MPa) and the yield strength is 48 ksi (331 MPa).

Covering type of E6013 Electrode

E6013 electrode flux coating contains rutile elements, cellulose elements, ferromanganese, and potassium silicate.

This is due to the element potassium compounds that permit this rod to work on AC with low amperages as well as lower Open-circuit voltages (OCV).

During the burning of coating, the flux coating of E6013 will mainly create carbon dioxide (CO2) gases.

Difference between E6012 & E6013

E6012 is different from E6013 by the type of electrode coating. E6012 covering is made of sodium, but the E6013 covering is made of contains potassium.

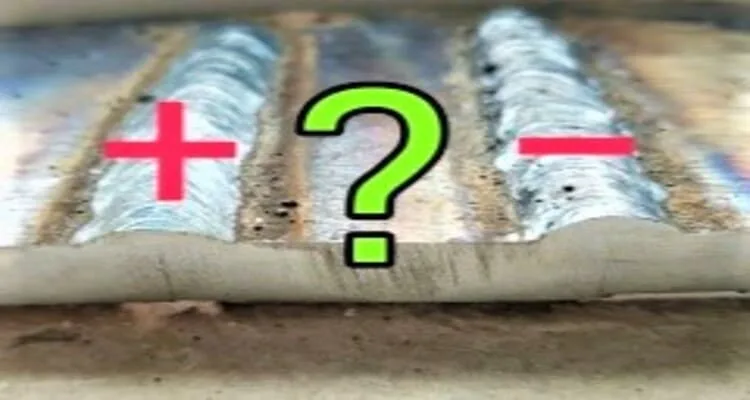

Both E6012 & E6013 can be welded with direct current electrode positive (DCEP) polarity but only the E6013 is can be welded with alternative current (AC) & Direct Current Electrode Negative (DCEN) polarity.

Stick welding using both E6012 & E6013 should be made using constant current (CC) type welders to counter the manual arc length variation during the welding operation.

Being a rutile-type stick welding rod, both E6012 & E6013 gives a smooth weld bead profile and easy slag removal with a smooth welding arc. This is because of a high amount of titanium dioxide (also called titania) in the electrode coating.

E6013 electrode Specification & classification

E6013 electrodes are classified according to ASME Section IIC, 5.1 welding rod Specification for Carbon steel rods for stick welding or E4313 as per CSA W48 or SFA 5.1M.

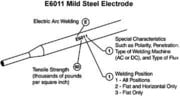

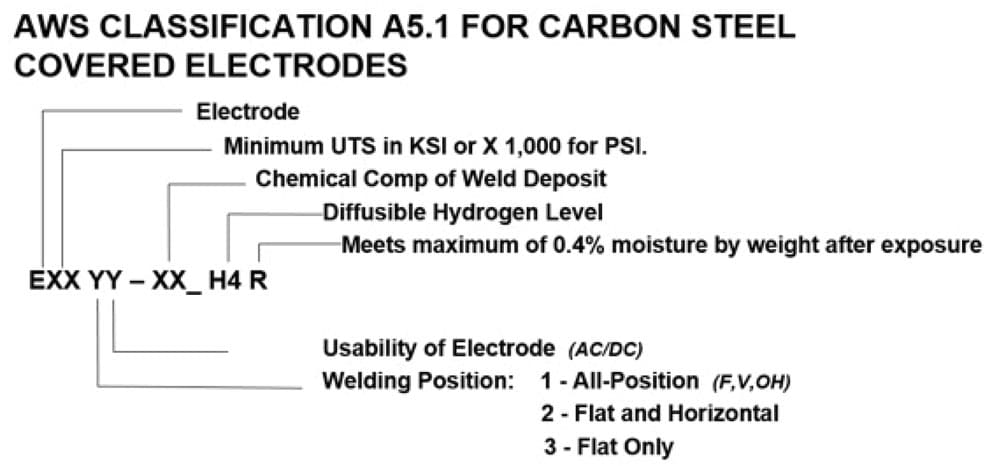

Similar to other welding electrodes, each digit in the E6013 electrode has its own meaning. These digits give very valuable information about this electrode as given below:

- ‘E’ stands for Electrodes for SMAW or stick welding.

- The next two digits i.e. ’60’ indicate the tensile strength of the weld deposit is 60 KSI or 60000psi.

- The next digit 1 indicates it is an all-position electrode which means F, V, OH, and H positions. Where ‘F’ = Flat, H = Horizontal, H-fillet = Horizontal fillet, V = Vertical and OH mean Overhead position.

- The last digit ‘3’ indicates it is High titania potassium and can be welded with only DCEP, DCEN & AC polarity.

Charpy V-Notch Impact (toughness) Requirements for E6013 type electrode

Charpy V-Notch or Toughness requirements are not specified for E6013 types electrodes in ASME Section IIC.

So, there are no requirements that can be placed on the electrode manufacturer & these electrodes are not designed for low-temperature applications.

E6013 Welding electrode Polarity

E6013 electrodes are can be welded with DCEP, DCEN & AC polarity

Storage & Baking/ reconditioning of E6013 Electrode

After opening the E6013 electrode packing, store the electrodes at 60°F to 100°F and below 50% relative humidity or in a holding oven at 100°F to 120°F (At ambient temperature.

E6013 types electrodes should be baked/ Reconditioning at a temperature of 275°F ± 25°F (135°C ± 15°C) for 1 hour.

What are Low Hydrogen electrodes, Their Storage & Baking Procedure?

Selection of current for E6013 Electrode

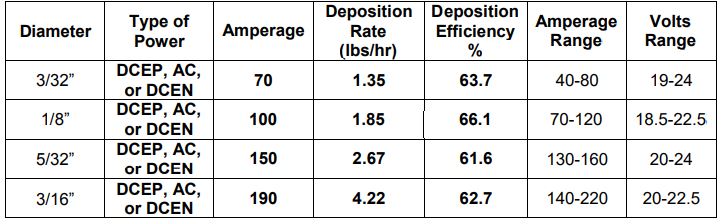

The correct welding amperage (current) setting mainly depends on the electrode diameter used. The below tables gives the recommended welding amperage for E6013 electrode diameter 3/32, 1/8, 5/32, 3/16, 7/32 & 1/4 inch sizes.

E6013 Electrode MTC sample

Sample Mill Test Certificate for E6013 electrode can be downloaded from here. A typical MTC contains 3.1 for chemical tests & 2.2 for mechanical properties.

The purchaser can request the full 3.1 for the mechanical properties, but usually, it adds extra cost to the electrode that has to be born by the purchaser.

When we say 3.1, it means full actual testing has been carried out for the electrode lot, and the results in the MTC guarantee the same properties for the weld metal.

In the case of 2.2 results, the values are typical and not the same as stated in the MTC although they will meet the minimum specified properties requirements stated in the AWS A5.1.