What is Material Test Certificate, How to read an MTC or MTR?

A Material Test Report (MTC), also called Mill test certificate or Material Test Report (MTR) is a product quality assurance document.

MTC is issued by the product (plate, pipe, fittings for example) manufacturers such as Nucor Corporation, Tata Steel, Arcelor Mittal & JFE.

The document complies with the material specification technical & delivery conditions.

E.g. ASTM A516 Gr. 70 plate needs to meet the technical requirements listed in ASTM A516 material specification & general requirements listed in ASTM A20 specification.

A material test certificate or MTC is an important document to ensure the quality of a part.

MTC shall be reviewed only by a competent person to ensure it meets the minimum requirements as per the material specification. MTC Means in manufacturing as Mill Test Certificate.

Who is the Supplier when buying materials?

The steel mill manufacturers the material in the required shapes such as plates, sheets, pipes or shapes.

Most of the fabricators then buy these materials via the suppliers who are linked between the mill & fabricators.

If the purchase order is big, mills also accept direct orders but it requires buying tonnage of material. Hence, fabricators usually buy material from stockiest who keep various types & grades of materials with them.

When buying material or considering a purchase, you can ask these suppliers to provide MTC for pre-review and client approval.

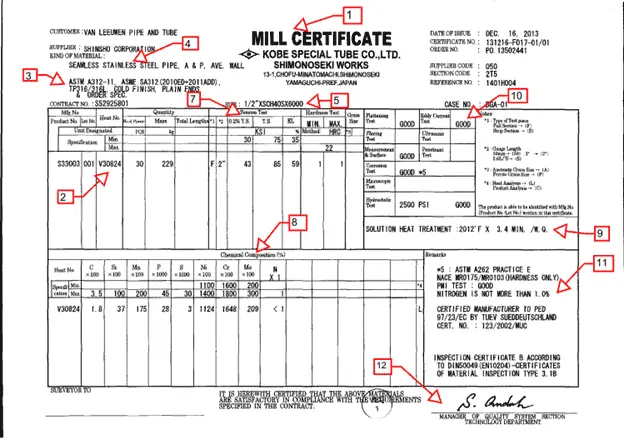

Refer to the MTC shown below for ASTM A312 TP 316/ 316L. The various locations on the information required to read an MTC are numbered in this MTC. Let’s understand each point so you can learn how to read & interpret an MTC.

Parts of a Material Test Certificates (Sample MTC/MTR):

The main parts of an MTC/MTR are:

- Manufacturer details & type of inspection certificate

- Material heat Number/ Lot number trace

- Material specification, grades, finish.

- Dimensions, weight

- Chemical composition & Mechanical properties, NDT record.

- Any additional tests.

- Signed & certified by the manufacturer.

Let us understand each of these parts and what information they provide in the MTC.

1. Material manufacturer

The top of the MTC contains the name of the company that has made the materials (plate/ pipe for example).

MTC contains full details about the manufacturer’s name, location, their logo & country of origin.

2. Heat Number or Lot Number & Technical delivery conditions

The material Heat Number or Lot Number (also called cast number) is specified in the MTC. Heat number means the single charge used in the final steel-making process.

The mechanical properties (Yield strength, tensile strength, & toughness), chemical properties, and product marking of material are linked with the heat number. These properties are called technical delivery conditions.

3. Material Specification & grade

Each MTC/ MTR must specify the specification number for the material and the grade of the material.

When reviewing MTC, these properties shall be matched with the minimum specified requirements in the material specification for technical and delivery conditions.

4. Delivery Conditions

The MTC has to comply with the delivery conditions for the material. An example of delivery conditions is the type of manufacturing process (hot rolled or cold rolled), seamless pipe or welded pipe, etc.

For example, material delivery for the above MTC example has to meet ASTM A312 specifications.

5. Dimensions

The MTC shall specify the material dimensions. For example, in the case of a plate, it will contain thickness, width, and length.

For tube or pipe, it will have the OD and wall thickness and pipe schedule and had to meet the tolerances permitted by the spec.

Fitting and connection sizes have to comply with the relevant codes such as ASTM B36.19M.

6. Material weight

The material weight in mass per unit length is usually specified in the test certificate & applicable for tubes and pipes.

7. Mechanical Properties in MTC

Mechanical properties in MTC are given for each heat number. The MTC usually specifies the minimum required mechanical properties as per the material specification and actually reported for the heat number for easy review.

As mechanical properties are one of the important parts of the MTC, they must be reviewed carefully and checked against the requirements.

8. Chemical Composition for material in MTC

Material chemistry in MTC is given for each heat number. The MTC usually specifies the minimum required chemical analysis as per the material specification and actually reported for the heat number for easy review.

The MTC usually specifies the chemical composition for product analysis and laddle (heat) analysis.

Product analysis means actual parent metal identification on the material while laddle analysis is carried out for each heat.

As material chemistry is also one of the important parts of the MTC, it must be reviewed carefully and checked against the requirements.

9. Heat treatment condition for the material

in MTC you will observe the heat treatment specified for the material. Here in this example, SS312 is a solution heat-treated at a temperature of 2012°F followed by 3-4 minutes of water quenching.

When reviewing the MTC, this information shall be verified with the material specification such as temperature range, time period, and type of heat treatment given.

10. Additional testing (Hydrotest & NDT)

Additional testing is usually carried out for material. You should refer to the material specification for additional test requirements and material compliance for these tests.

For example, pipes are usually hydro-tested, plates are ultrasonically tested and duplex stainless steel materials are tested for microstructure.

11. Supplementary information & testing requirements

Any supplementary testing requirements as agreed between the purchaser and the manufacturer shall be listed in the MTC.

Verification shall be carried out based on the purchase order requirements.

12. Manufacturer seal & signature

Each MTC/ MTR shall be signed and stamped by the manufacturer’s authorized personnel to make it an authentic and acceptable quality document.

This is also a mandatory requirement for the quality manual system.

The signature & stamp also guarantee that the information provided in the MTC is true and correct.

FAQS

What is a MTC Report?

A MTC Report is a non-standard term used for Test Certificate. A Mill Test Certificate or MTC has all the essential information required for the product and it is not supplemented with a MTC Report.

Full form of a MTC report is Mill Test Certificate Report but the right term is MTR which means a Mill Test Report (Also called Mill Test Certificate or MTC).