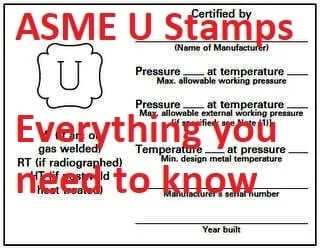

ASME Stamp Meaning

The ASME stamp or certification mark (MARK) is a globally recognized symbol of quality and safety in the fabrication of ASME code vessels and other equipment. It serves as an assurance to customers that the product meets all applicable codes and requirements, ensuring that it is safe for use.

It shows that a product has been designed, manufactured, assembled and tested according to ASME’s rigorous codes.

The process for obtaining an ASME stamp or certification mark requires extensive work including quality assurance, testing, inspection and documentation to ensure that products are safe for use.

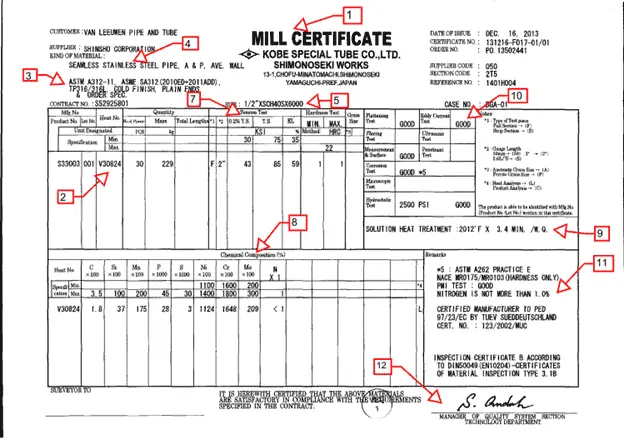

Companies must adhere to strict guidelines set by ASME including materials selection and proper design methods; the product must be constructed using approved materials; welding procedures must meet specified requirements; parts must be adequately tested through destructive & non-destructive testing; all personnel involved in the process need to have appropriate qualifications; and finally, inspection records must be kept on file.

Validity of ASME Stamp certification

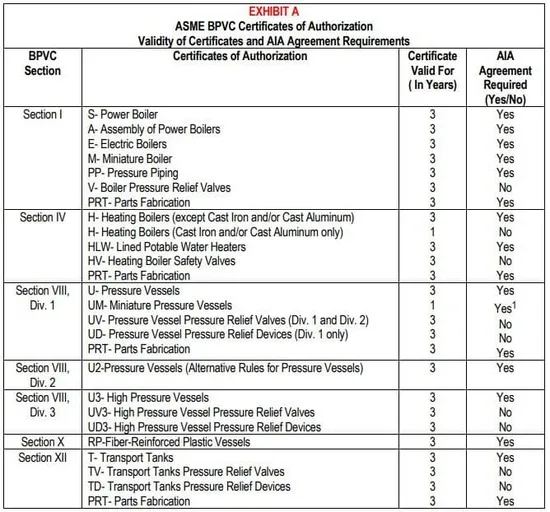

The validity of an ASME Stamp certification is generally three years from the date of issue.

H stamp (Cast Iron and/or Cast Aluminum) as per ASME Section IV & UM stamp (Miniature Pressure Vessels) as per ASME Section VIII, Div. I are valid for only one year. In the below table validity of the ASME stamps list is given:

Manufacturers must be aware that if their product’s original Stamp expires, they must reapply for a new one in order to remain compliant with industry standards. ASME send reminder 10 months before expiry to the certificate holders.

In order for a manufacturer to maintain its ASME stamp marking certification throughout its three-year validity period, it must be re-audited, inspected, and tested on a regular basis to ensure it continues to meet all code quality & safety requirements.

Read more: What is ASME U Stamp Marking?

ASME Stamps List (Certification mark)

The American Society of Mechanical Engineers (ASME) is widely recognized as the leading authority in determining what materials and components can be used in various applications.

The ASME stamps list provides a detailed breakdown of approved items that can be used in specific applications, giving engineers the confidence to use products that have been tested and certified for safety and performance.

The ASME stamps list is comprised of many different categories, including pressure vessels, boilers and nuclear components that are all reviewed according to stringent standards set by the organization.

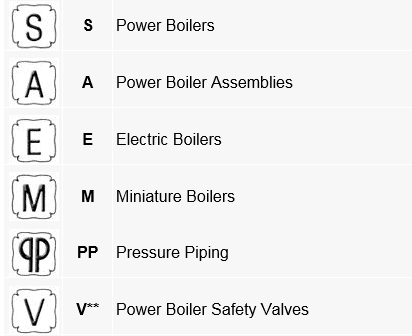

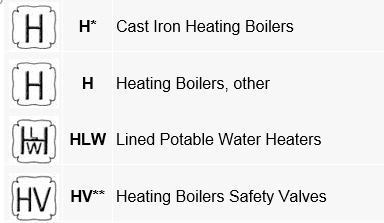

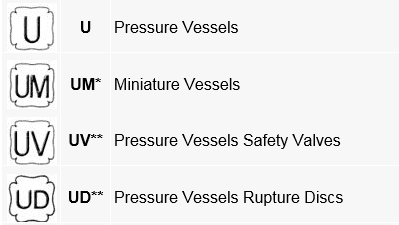

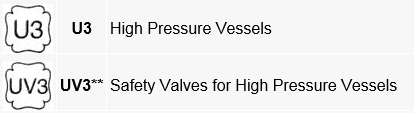

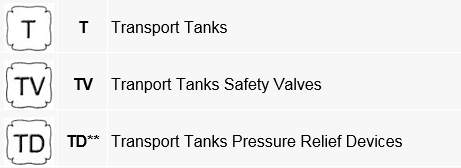

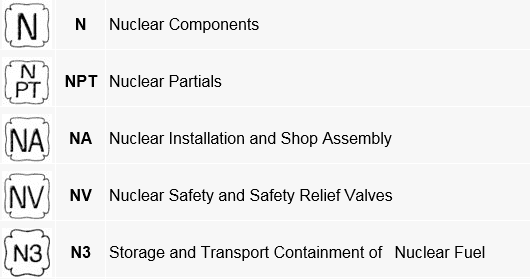

Following are the ASME stamps offered by ASME under the ASME BPVC Certification Program for manufacturers:

Images credit: Shipbuildingknowledge blog

ASME Stamps List and Requirements

ASME Stamps for Power Boiler Construction: Section I

ASME Stamps for Heating Boilers Construction: Section IV

ASME Stamps for Pressure Vessels Construction: Section VIII- Div. I

ASME Stamps for Pressure Vessels Construction: Section VIII- Div. II

ASME Stamps for Pressure Vessels Construction: Section VIII- Div. III

ASME Stamps for Reinforcement Plastic Vessels Construction: Section X

ASME Stamps for Reinforcement Plastic Vessels Construction: Section XII

ASME Stamps for Nuclear applications Construction

How to apply for ASME Stamp: Step by step

1. Preparation

1.1 Selection of accreditation procedure: The manufacturer must select the accreditation procedure(s) for which he wishes to apply. In total there are 17 symbol stamps plus 4 for nuclear components. An overview of all code symbol stamps is given above.

1.2 Select

Authorized Inspection Agency (AIA) When selecting the AIA, it must be taken into account that the AIA must be accredited for the corresponding field of application. (List of AIA).

1.3 Conclude a contract with the selected AIA It is necessary to conclude a contract with an AIA accredited by ASME in order to regulate the cooperation between the manufacturer and AIA. This contract must be submitted to ASME.

1.4 Acquisition of the ASME Code Depending on the planned accreditation procedure (see 1.1), the required sections of the ASME Code must be purchased. The overview shows the required code sections.

2. Submit

An application to ASME Only original ASME application forms must be used for the application, which can be requested informally from ASME.

The application must indicate, among other things, the planned accreditation procedure (see 1.1), the commissioned AIA (see 1.2) and the address(es) of the production facilities to be covered. Approximately 3-5 months can be expected between the application and the »shop review«.

3. Set a date for the »Shop Review« with ASME.

The date proposed by ASME must be confirmed or, if necessary, an appointment must be made with ASME. The entire cost including advance payment for travel expenses must be paid in advance.

4. Preparation of the Quality Assurance Manual

The manufacturer must prepare a quality assurance manual where all code requirements including materials, design, manufacture, NDE testing, pressure test, acceptance by the AIA and certification are taken into account.

The quality assurance manual with the required process descriptions (NDE tests, heat treatment, handling of welding consumables, written practice, etc.) must be in English. Other language editions can be used later for the internal application, but the English language output is binding for accreditation.

The ASME quality assurance system may also be integrated into another manual, e.g., ISO 9001, but it must be clear which parts of the manual meet the code requirements.

5. Implement

Quality system: The manufacturer must implement his quality system.

6. Preparation for the »Shop Review« Preparation of an order.

If there is no ASME order, a demonstration order must be created on the basis of which the processing of the order can be demonstrated at the »Shop Review«.

-Preparation of drawing and calculation-Qualification of welding procedures (WPQ)-Qualification of welders (PQR)-Create welding instructions (WPS)-Qualification of NDE test procedures by demonstration in the presence of the Authorized Inspector (AI).

-Qualification of NDE personnel-Material Ordering-Creation of a quality assurance plan-Issuing of the Manufacturer’s Data Report.

7. Implementation of the »Shop Review«

As usual with other audits, the time required for the review depends on the size of the company and ranges from e.g., 1 auditor / 2.5 days for a 25-man company to 4 auditors / 4.5 days for a 5000-man company. In addition, the audit team includes an auditor (AIS) from AIA.

The shop review usually proceeds according to the following scheme:

– Review of the quality assurance manual- An opening meeting- Report on the review of the quality assurance manual.

– Review of the implementation of the QA system with factory inspection- Internal meeting of the audit team with resolution on possible non-fulfillment points.

– Final meeting with the announcement of the result.

The result of the shop review can be:

– the »Certificate of Authorization« can be issued- a new shop review is required, or

– nonfulfillment points can be accepted by the AIA within 30 days.

However, if the AIA again detects non-fulfillment points, a new shop review is required

8. Certificate of Authorization and stamp After a successfully completed shop review, ASME will hand over the Certificate of Authorization and the corresponding stamp to the manufacturer.

9. Applying for the »Certificate of Authorization for Registration«

In order to register the stamped containers with National Board, this Certificate of Authorization for Registration is additionally required. All you need to do is submit the ASME Certificate of Authorization and a copy of the Quality Assurance Manual to the National Board.

10. National Board Sends Certificate of Authorization for Registration to Manufacturer

Code Stamped containers can now be registered with National Board.