AWS D1.1 vs. CWB W47.1

CWB W47.1 is a welding Standard issued by the CWB for welding related industries seeking certification to meet Canadian construction & welding standards requirements, including welder performance qualification & welding certification.

On the other hand, AWS D1.1 is a CODE used as a welding and testing guide for companies in the United States and other countries around the world as its user.

W47.1 does not require welding conditions (such as prequalified joints) like D1.1, it only specifies what a company must do to become certified for its welded products to be used in Canada.

The Canadian equivalent of AWS D1.1 is CSA W59. There is no US equivalent to W47.1 at the moment, as US companies do not need to be AWS D1.1 certified alike in Canada where companies need to be certified according to W47.1, they are simply recommended” to use it (in some cases).

Related Reading: CSA W47.1 vs CSA W47.2

Government law requires the use of W47.1 and W59 for all structures to be used in Canada.

CSA W47.1 & W59 standards provide requirements for companies certification engaged in steel welding, as well as qualification requirements including welders, welding processes, and welding supervisors.

Weld quality, base material/electrode match, prequalified connections, & design for weld. AWS D1.1 that is Code for steel Structural Welding, gives the qualification requirements for welder & procedure as well as provides guidelines for welding design, NDT & fabrication for structural works.

It also specifies the quality of the weld seam, the coordination of the electrode/base material, the prequalified connections, and the construction of the weld seam.

These CWB standards covers the welding requirements for procedure qualification, for welder qualification, including welding consumables, design and companies.

The attached documents (Click here) from CWB provide a detailed difference between the AWS D1.1 and CWB W47.1.

Canadian Welding Standards

The main standards that provide general requirements related to welding & allied processes in Canada are given in CSA W47.1 & W59.

When we see for the US, welding-related conditions are given in AWS D1.1 for structural fabrication, ASME Section VIII, IX for welding of pressure vessels, and ASME B series for piping while the requirements for the European Union are given in ISO 3834.

Canadian Standards Association is the controlling body in Canada for welding standards .

In particular, CSA W47.1 & W59 standards regulate welding & welding/welder/operator qualification requirements. Welding quality requirements are also covered in these standards.

Related Reading: Overview of CSA 47.1 Standard

To obtain and retain certification, each company & their individual personnel must qualify their personnel in accordance with recognized welding procedures, welding technology, and supervisory functions.

CWB is the main welding body that is controlling welding standards, qualification of welders, welding inspectors, welding supervisors, welding engineers, etc. in Canada.

CSA Standards has specified the requirements for the qualification & certification requirements for welding engineers, welding supervisors as an individual level certification as well as for manufacturers who perform welding related activities.

American Welding Standards/ Codes

in the USA, welding codes are prepared by independent non-profit organizations such as ASME (American Society of Mechanical Engineering) AWS (American Welding Society) or API or ANSI or ASTM for example.

American Welding Society (AWS) is the main body, which creates the largest number of welding standards & codes in the United States of America.

Its most used code from D-Series is AWS D1.1 and other codes in the D Series for different types of fabrication.

There are Series A, Series B, Series C, etc. for different categories such as welding guidelines, specification & standards etc.

Also, ASME, AWS creates the codes & standards for boilers & pressure piping (E.g. ASME Section IX, ASME B31.3), which include the fabrication requirements, design, materials types, their selection, testing & inspection requirements for boilers, pressure vessels & piping.

The American Petroleum Institute or the API has their own welding standards for oil & gas. The mostly used is API Standard 1104 for the welding pipelines for oil & gas.

The most important AWS codes are:

- C 5.4 Stud Welding

- D 1.1 Steel

- D 1.2 Aluminium

- D 1.3 Sheet Steel

- D 1.4 Reinforcing Steel)

- D 1.5 Bridge Welding Code, All Metric

- D 1.6 Stainless Steel.

The most important code of the AWS is D1.1 /22/ which is being applied for the welding of load-carrying constructions of steel in the constructional area and mechanical engineering. AWS codes contain both metrics as inch measuring units.

European Welding Codes & Standards

In the Europe, the Welding Code term is not used and most of the welding standards are derived from DIN (German) standards.

For welding, ISO 3834 standard series gives welding quality requirements and is a international welding standard prepared by professional welding associations that defines the welding quality requirements.

ISO 3834 ensures through standardized testing that the welding company has skilled and well qualified welders.

These welders using qualified WPS (welding procedure specification) for all welding activities.

Here, WPS is a written welding documents for welder to aid them to perform the on job welding. Most of the European standards are adopted by the UK and termed as BS ISO standards.

In ISO standards, most notably welding standards are ISO 15614 series for WPS qualification, ISO 9606 series for welder/ operator qualification, EN 1090 for structural fabrication, and the ISO 3834 series for welding quality control certification.

Welding Standards in Australia

Australia has its own welding standards which are being used by Australians and New Zealander’s users.

In Australia, welding companies also follow ASME, AWS, ISO, and API codes & Standards also.

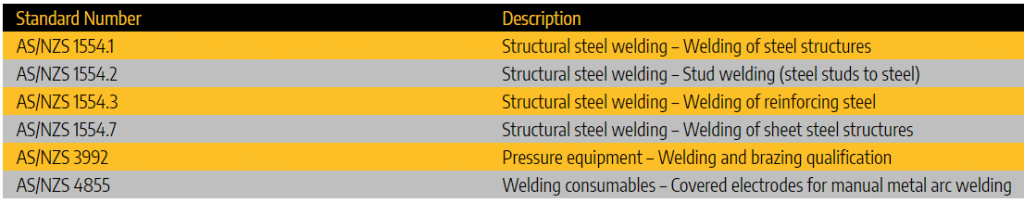

Standards Australia (AS) is the body responsible for the development, maintenance, and publication of Australian Standards. A brief summary of Australian Welding Standards are given in below table:

ISO Standards

The International Standardization Organization (ISO) is the association of all National Standard Committees involving are around 145 members nowadays. ISO supports several technical committees (ISO/TC).

Every country is allowed to be active inside these technical committees. However, only a few countries can afford themselves to be active inside all technical committees due to financial reasons. ISO/TC 44 is concerned with welding and allied processes.

A list of ISO Standards can be downloaded from this link.

Correlation between DIN EN and ISO Standards

In Germany, a differentiation is made between DIN, DIN EN, DIN ISO, and DIN EN ISO Standards. In general:

DIN: German Standards are only valid in Germany.

DIN EN: European Standards adopted by DIN (adoption obligation).

DIN EN ISO: Standard is valid in all CEN and ISO countries and is automatically a German Standard.

DIN ISO: ISO Standard being adopted by DIN without being a European Standard (will not happen anymore in the future).

Standards for Welding Quality Assurance

For many years the assurance of weld quality has been defined by DIN 8563 in Germany.

This Standard was valid for the welding of metallic construction products during manufacturing and maintenance for which a specific quality level was required due to legal regulations, commonly accepted rules of technic or based on procurements contracts.

DIN 8563 did create a uniform base, aiming to specify the manufacturer’s suitability for professional execution of welding activities according to equal criteria and to be evaluated according to similar basic principles.

DIN 8563 part 1 and part 2 have been withdrawn and exchanged by DIN EN ISO 14731 and the Standard series of DIN EN ISO 3834.