How to Write a WPS- Basics

a WPS is a document that supplies the necessary information to a welder to execute a job.

All the welding parameters that can affect the welding properties in terms of mechanical properties only and not the technological are listed in a WPS.

But first what is a WPS?

- The full form of a WPS is Welding Procedure Qualification.

Steps for Writing a WPS

Remember, a WPS is written according to a Welding Code or Standard that lists the prerequisitions, limitation and ranges for welding parameters.

- These documents also give the procedure on ”How a WPS can be qualified?”

When we say ” A Qualified WPS”, what does it means?

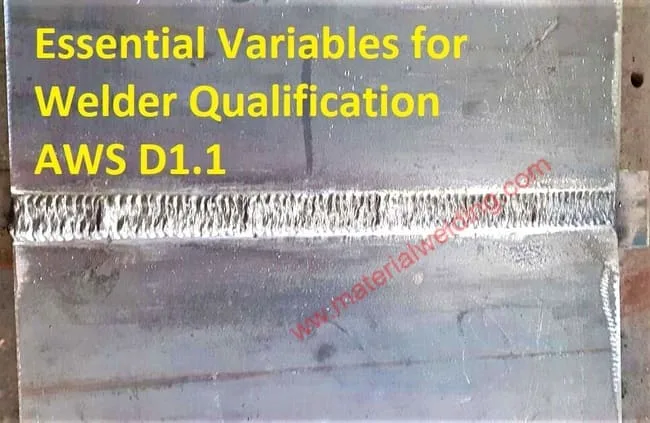

A Qualified WPS refers to a Welding Procedure Qualification that has been carried out according to a Qualification code such as AWS D1.1 or ASME Section IX or ISO 15614-1, for example.

First, a test coupon is welded using a pWPS and then tested for mechanical properties. The test results are documented by a Procedure Qualification Record (known as PQR).

Read my article on What is PQR and its qualification procedure?

If all the test results meets the minimum specified requirements, then we say that the WPS is Qualified.

Back to, WPS Writing steps

Follow these steps to make your start.

- First, you need to know what is your qualification Code.: ASME Section IX or AWS D1.1 or API 1104, etc.

- Next, use the recommended WPS format given in the code as a reference to list out the welding parameters.

Now, we shall make a pWPS first.

- Fill out all the parameters given in the WPS format. Either they are essential or non-essentials parameters.

Read this article to learn about what are Essential, Supplementary, Specila and Non-essentials Welding parameters.

- keep the requirements in the format as per your actual job requirements. For example, actual job thickness, grade, proposed welding filler rod, welding gas, etc.

- Once, you fill all the welding parameters, review them if they covers all welding requirements you need for your job.

- You can use one WPS for different materials, and welding rods as permitted by welding codes. For example, welding one material grade, you can use the same WPS for different material grades.

- But for this you must know different welding terms as listed below:

Going through above posts, will guide you about the qualification ranges permitted by welding codes for different material grades and welding rods.

Continues………..

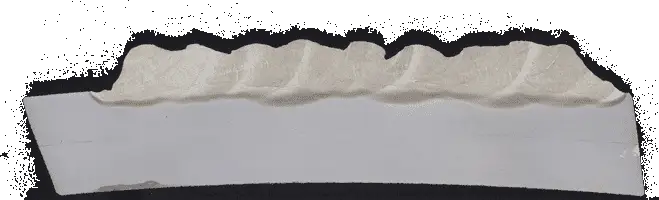

- Make a test assembly as per the code dimensions requirements ( a groove weld or T-Joint or a weld overlay qualification).

- Carry out the welding as per pWPS and record all the welding variables on a PQR Sheet format (refer to code for suggested format).

- Carry out the testing as required by the code such as tensile test, bend test or any other supplementary test.

- If results are acceptable, YOUR WPS IS QUALIFIED.

“Write a WPS within the range for each variable that is permitted by the welding code for your actual variable. You need to refer the welding variables tables in the code for this.”

— Welding Engineerr

This article is part for Writing a Welding Procedure Specification.