Essential variables in Welding are those variables that affects the mechanical & technological properties of a welding. They are classified for:

- Essential variables for WPS Procedure Qualification

- Essential variables for Welder Performance Qualification

This article covers Essential Variables, Non-Essential Variables & Supplementary essential Welding for WPS & Welder qualification both.

What are Welding Variables?

It is important to remember that the requirements of different welding codes and standards (E.g. ASME Section IX, AWS D1.1, or ISO 15614-1) have been adjusted to meet specific service requirements.

Each welding code and standard such as ASME Section IX or AWS D1.1 or ISO 15614-1 have given & considered:

- Essential,

- Nonessential, and

- Supplementary essential variables differently.

Hence, to properly develop welding documents such as WPS, PQR, or WPQ, shall be reviewed by competent qualified Welding Engineer or Welding Inspector.

These qualified and responsible person shall review and decide the relevant & applicable welding variables such as essential, non-essential and supplementary essential variables for each qualification. A righteous review will ensure the documents comply to the code requirements to maintain the welding quality on job.

A qualified PQR & WPS specifying these variables within the qualified range is mandatory for a good welding quality and integrity. This is hence essential to perform this task with proper due diligence and utmost care.

A variable listed on a wps is required to be comply the qualification code. For example, ASME Section IX, requires all essential variables, non-essential & supplementary essential variable to be listed in WPS.

What is Essential Variable in Welding?

Essential welding variables are listed in the ASME Section IX, clause QG-105.1, QW-251.2, and QW-401.1.

For Essential Welding variables, a change in the essential variable is considered to affect the mechanical properties (E.g. tensile strength, yield strength & ductility) of the weldment and shall require the requalification of the WPS. Hence, the WPS must be requalified, if any of the essential variable is changed.

Examples of Essential variables are P-Number for base metal, welding process or PWHT, etc.

Examples of Essential Variables in Welding for WPS

The examples of some essential welding variables as per ASME Section IX are:

- Base Metal P. Number

- Base Metal Thickness qualified range

- Decrease in preheat temperature more than 100 Degree Fahrenheit

- Change in PWHT

What are Supplementary Essential Variables in Welding?

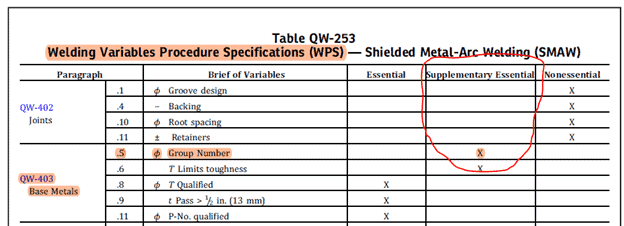

Supplementary Essential welding variables are listed in the ASME Section IX, clause- QG-105.3 & QW-251.2, QW-401.3

Supplementary essential variable affects the weld toughness properties (CVN). So, the supplementary essential variables shall be considered as essential variables for procedure qualification (WPS-PQR) when CVN toughness is applicable for the welding.

For example- a pressure vessel fabrication has toughness requirements for its weld, then supplementary essential variables must be considered too.

If there is no requirements for weld toughness, supplementary essential variables are non-essential variable only. For example- a weld operating at elevated temperature does not requires weld toughness as material is already having good ductility a high temperature.

Examples of Supplementary essential variables are for example- Group Number for base metal, thickness limit qualified in the PQR.

Watch this YouTube video for full classroom training on Welding variables, their types, and practical Importance.

Watch the online video and learn:

- What is the welding variable?

- Types of welding variables?

- Procedure and Performance variables?

- What are essential, supplementary, Non-essential, and special variables?

- Importance of welding variables?

Examples of Supplementary Essential Variables in welding for WPS

The examples of some Supplementary-essential welding variables as per ASME Section IX are:

- Change in Material Group Number,

- Change in material thickness qualified as per QW403.6,

- Change in welding rod or filler wire classification (e.g., changing from E7018 to E7015).

- Increase in more than100°F (55°C) interpass temperature than qualified,

- Change in PWHT (T & T range),

- Increase in Heat input than qualified,

- Change in Current or polarity,

- Change Multiple to single pass/side.

Note, above Supplementary-essential welding variables are for SMAW process. They can change from one process to other but above list is mostly applicable for all process. For complete list, refer to ASME Section IX QW-253 tables.

What are Nonessential Variables in Welding?

Non-Essential welding variables are listed in the ASME Section IX, Clause- QG-105.3 & QW-251.3, QW-401.4

Nonessential welding variables refers to those conditions in which a change can be done without the need to requalify the existing WPS. The reason- changes in these variables does not affects the mechanical properties of the weld.

Although a change in the nonessential variable doesn’t require prequalification of the WPS but as per ASME, these variables shall be specified in the welding procedure specification (WPS).

Examples of non-essential welding variables for WPS qualification are:

- Joint design,

- filler wire/ electrode diameter

- Root spacing

- welding position

- weaving or stringer bead

- Peeing

- Preheat maintenance

- single pass/ multipass

- Cleaning methods

Examples of non-essential welding variables for Welder Performance Qualification are:

- Root spacing

- Electrode Diameter

- Welding current, voltage

- Travel speed

- Gas shielding

- Base metal group Number

- Base metal thickness

Examples of Supplementary Essential Variables in welding for WPS

The examples of non-essential welding variables as per ASME Section IX are:

- Material Group Number

- Weld metal Thickness qualified limit

- Change in welding rod classification

- Increase in interpass temperature

- PWHT (Time & temperature change)

- Welding Heat Input

- Welding current & voltage

What are Special Process Variables?

Special welding variables are listed in the ASME Section IX, Clause- QG-105.4 & QW-251.4

Special process variables are conditions that apply only to special processes (Such as corrosion resistance overlay & hard-facing) that are described in the ASME Section IX.

Special processes are such as weld overlay applications. These processes are used for special purposes instead of joining applications.

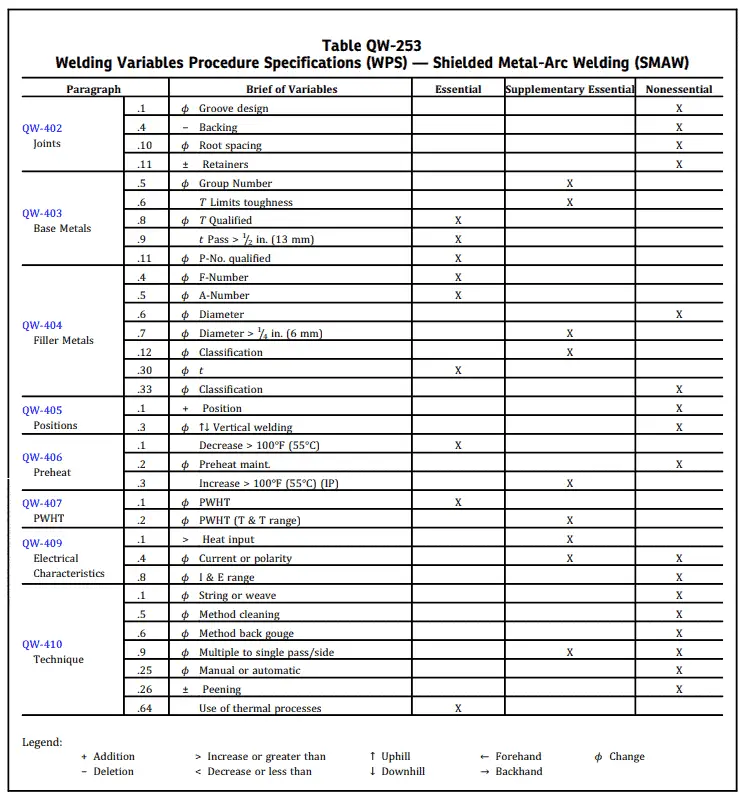

WPS essential Variables

WPS Essential Variables are those conditions that influence deposit weld mechanical properties. Any change in these variables other than qualified will alter the mechanical properties of the welding. These properties can be:

- Tensile Strength

- Yield Strength

- Toughness

- Hardness

- Ductility

- Microstructural changes

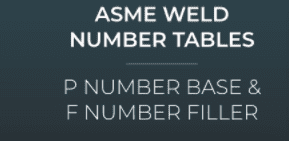

Essential variables are listed in ASME Section IX QW-452 to QW-267 Table. Essential variables examples are:

- Base Metal P-Number

- Welding Electrode F-Number

- Weld A-Number

- Welding Preheat

- PWHT

- Qualified PQR Thickness (T)

- Thickness (t) of weld deposit qualified

List of Essential and Nonessential variables in welding

Essential and Non-Essential Variables in Welding are covered in ASME Section IX for:

- WPS Procedure Qualification

- Welder Performance Qualification

WPS Qualification List of Essential and Nonessential variables in welding can be found in Table QW-452 to QW-267 for different welding processes. Below is the list of Essential and Nonessential Variables for WPS Qualification.

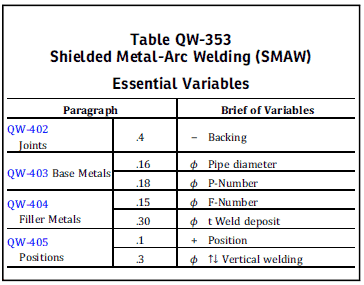

Welder Performance Qualification List of Essential and Nonessential variables in welding can be found in Table QW-352 to QW-357 for different welding processes. Below is the list of Essential Variables for Welder Performance Qualification.

- Removal for backing

- Change Base Metal P-Number

- Change in Pipe diameter

- Change in F-Number

- Change in t-Weld qualified

- Addition of a welding position

- change from vertical uphill to downhill

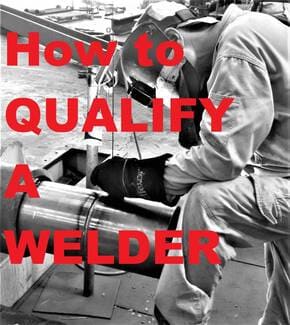

Essential Variables for Welder Qualification

Essential Variables for Welder Qualification are those variables that affect the welder ability to make a sound weld deposit. So basically, essential Variables for Welder Qualification influence the weld quality in term of soundness.

Essential Variables for Welder Qualification are listed in Table QW-352 to QW-357 for different welding processes of ASME Section IX, QW-352 to QW-357 for different welding processes for SMAW Welding process are given below (Taken from Table QW-353).

- Removal for backing

- Change Base Metal P-Number

- Change in Pipe diameter

- Change in F-Number

- Change in t-Weld qualified

- Addition of a welding position

- Change from vertical uphill to downhill

What must be done if an essential variable on a WPS is changed?

If an essential variable on a WPS is changed beyond the range qualified, it require re-qualification of the WPS by welding a new PQR. This condition is specified in ASME Section IX QG-105 clause.

An essential variable on a WPS is changed can be addressed in two ways:

- Change in an essential variable within the range qualified

- Change in an essential variable beyond the range qualified

For Change in an essential variable within the range qualified, can be made by revising the WPS as editorial revision.

For change in an essential variable beyond the range qualified, this required re-qualification of welding procedure by welding a new test coupon and testing it according to the welding qualification code, such as ASME Section IX or AWS D1.1.

can you provide some examples of supplementary essential variables?

The examples of some Supplementary-essential welding variables as per ASME Section IX are:

1. Change in Material Group Number,

2. Change in material thickness qualified as per QW403.6,

3. Change in welding rod or filler wire classification (e.g., changing from E7018 to E7015).

4. Increase in more than100°F (55°C) interpass temperature than qualified,

5. Change in PWHT (T & T range),

6. Increase in Heat input than qualified,

7. Change in Current or polarity,

8. Change Multiple to single pass/side.