What is Metal Core Welding (MCAW)

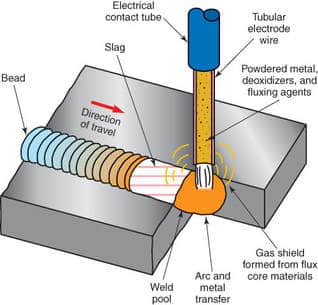

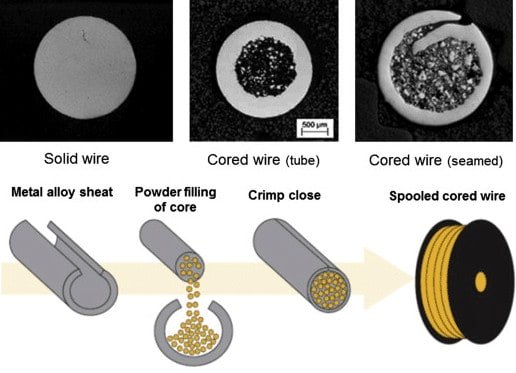

MCAW (Metal Core Arc Welding) is an arc welding process that uses a continuous wire rod with a shielding gas blanket similar to GMAW process. Metal core arc welding electrode are hollow tubular wire filled with metal powder & some welding arc stabilizing elements.

The process incorporates shielding from an externally supplied gas and is used without the application of pressure, which makes it purely a fusion welding process. Metal core arc welding can be implemented in semiautomatic and automated operations. It can be used for the welding of mild steel, carbon steel, stainless steel, low alloy steel, and other ferrous materials.

MCAW wire process is having a high burn-off rate that offers higher welding travel speeds and increased weld deposition rates, mainly in comparison to flux cored and solid wires.

Metal core wire also helps to reduce welding defects such as porosity, lack of fusion, and undercut. The picture above shows a good weld made with metal-cored wire.

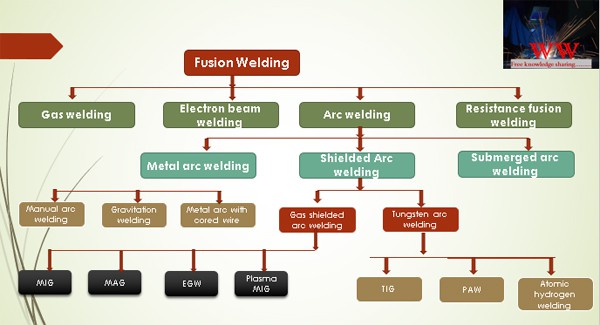

138 Welding Process

Metal Core Arc Welding or MCAW is a type of MIG-MAG welding process which falls under Gas Shielded Metal Arc Welding processes.

Metal-active gas welding with metal-core wire (MCAW) is designated with Number 138 as per ISO 4063. The MCAW process uses a DC Welding power source, a wire feeder, and a welding gun similar to MIG MAG Welding.

What is Metal Cored Welding Wire?

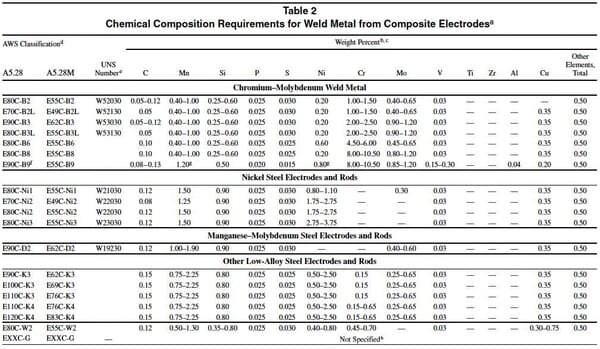

Metal cored welding wire also called composite welding electrodes. Metal cored wires are classified in AWS A5.28 & AWS A5.36 for carbon steel and low alloy steel.

Below are the metal cored welding wires grades and their chemical properties as specified in AWS A5.28 Table 2.

AWS SFA 5.36 gives the classification of low-alloy steel metal-cored welding wire for a gas metal arc (GMAW), gas tungsten arc (GTAW), and plasma arc (PAW) welding.

Metal cored welding wire is a type of cored wire filled with metal powders, alloying elements (For higher toughness and strength), and welding arc stabilizers, and de-oxidizers inside the wire core.

Metal cored welding wire have characteristics of FCAW-cored & GMAW-solid wire but not containing any flux with instead replaced by metal powder.

Types of MIG-TIG Welding Wire

Each of the elements added to the core, provides special characteristics to the welding, for example, providing additional alloying elements, arc stabilization, higher arc efficiency, etc.

Metal cored welding wire Examples

Metal Cored welding wire are classified in:

- AWS A 5.28: Low alloy steel metal cored wires such as E90C-B9, E70C-Ni2, E80C-B8 and E90C-D2.

- AWS A5.36: Carbon steel & low alloy steel metal cored welding wires such as E70C-6C, E70C-8M, E90C-B9.

- CSA W48-01: E.g., E49C-6C.

Meaning of Metal cored Welding wire classification:

Lets take example of E70C-6M. Here,

- ‘E’ means Electrode

- ’70’ means 70 Ksi minimum tensile strength

- ‘C’ means metal cored wire

- ‘6’ indicate the chemical composition of the wire rod

- ‘M’ means rod to be used with argon-Co2 gas mixture

Metal Core wire has the same basic chemical composition and mechanical properties as solid welding wire but is marked with a “C” for composite wire.

For example, an 80 KSI metal core wire with similar chemical composition and mechanical properties to an E80S solid wire would be classified as an E80C6 composite wire.

Metal cored wires have similar properties to cored wires and different properties to solid wires.

MCAW vs. FCAW (Flux Cored vs. Metal Core arc Welding)

MCAW vs. FCAW or Metal Core Arc Welding versus Flux Cored Arc Welding has the main difference between the type of Welding Wire.

In MCAW, the Welding Filler wire is cored wire similar to FCAW but instead of flux covering (Like in FCAW), the core of an MCAW wire is filled with metal powder & alloying elements.

In flux core arc welding or FCAW, it is possible to use wire without any external shielding gas (e.g. in the case of FCAW-S) but in Metal Cored arc welding or MCAW, it is a must-have an externally supplied welding shielding gas to protect the weld pool.

Mig Welders vs Stick Welders: What’s the Difference?

Metal Core Wire (MCAW) vs. Solid Wire (GMAW)

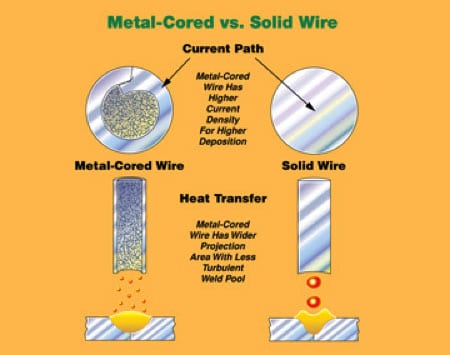

Metal Cored Wires are similar to Solid MIG wires in many ways. They can be used for the same welding power source, need similar welding gases, and deposit similar strength welds.

Compared to solid wire, metal-cored wire offers a higher deposition rate, lower weld spatters, and fewer welding defects.

Below figure shows the weld deposition comparison between metal cored welding wire and solid gmaw wire. Metal cored welding wire offers higher weld deposition compared to solid wire.

As shown in the below picture, the metal-cored wire has a higher current carrying density compared to the solid wire which helps to increase the weld deposition rate.

Compared to GMAW, Metal cored welding provide wider and better rounded weld bead when using with argon rich welding shielding gas.

The slag produced by metal cored welding is similar to GMAW which is little to no slag formation on welds. Compared to GMAW, metal cored welding wire produces very less welding fumes which is good from safety aspects.

Metal Cored Wire Flux-Cored Wire

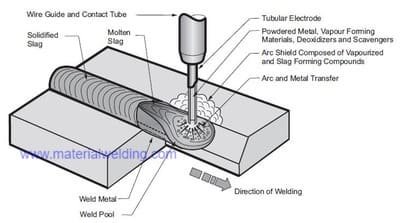

FCAW wires are opposite to stick welding rod and we can say inverted stick welding (SMAW) rod.

Metal cored wire is like Flux Cored Arc Welding wire as both are tubular wires as shown in the below figure. But Metal cored wire offers a higher weld deposition rate compared to flux cored arc wires.

But the Metal cored wire doesn’t have any slag-forming elements in it as they are filled into the flux-cored wire. This helps to give higher productivity with metal-cored wire compared to FCAW and solid wires.

The wire doesn’t produce any slag so welding efficiency is increased. Also, with the addition of arc stabilizer elements, there are fewer spatters compare to solid wire.

Compared to FCAW, MCAW produces very little welding fumes, gives higher welding duty cycle and high weld quality deposits.

Advantages of Metal Cored Wire

Metal cored wire with a spray transfer mode offers a very good profile, deeper penetration, and spatter-free welds. With Spray transfer, you can maximize the benefits of metal-cored wire by:

1) You can weld faster due to the higher melt-off rate, and

2) Spray transfer produces little to no spatter, so it will minimize post-weld cleanup.

in summary, metal-cored wire gives:

- The high deposition rate and arc efficiency.

- Improved weld profile with high welding quality.

- Higher travel speed & duty cycle.

- Reduced welding defects.

- Due to added deoxidizer, easy to use on rusty surfaces.

- Deeper weld penetration.

- Stabilized welding arc.

- Less welding fumes.

- Very little to no welding slag.

Tips and techniques for Metal Cored Arc Welding

Perform the Metal Cored Welding similar to MIG-MAG with solid wire, and take notes of the below precautions.

- Use only V-knurled drive rolls. You can simply crush metal-cored wire when there is high much pressure which can be applied by a U-groove roller.

V-knurled drive rolls with a small knurled area to grip and guide the cored wire and gives low pressure to push the wire to the liner in the torch.

- Keep longer stick out: Contact tip to work distance (CTWD) shall be kept longer with metal-cored wire compared to solid wire.

A gap of 1/2 inch and 1 inch (depending on wire diameter and operating point) is recommended for a good result. Typically, longer tip-to-work distances are suggested as wire feed speed and wire diameter rise.

- Use a larger wire diameter: As the wire density is higher in metal-cored wire, you can use a higher wire diameter without compromising the overall welding current.

- Less manipulation of welding torch is good: Metal cored wire offers good arc stabilization, thus you do not actually need much welding torch manipulation.

Metal Core Arc welding electrodes Specification

Metal core arc welding electrodes/ filler wire rods are covered in:

- AWS A 5.28: Example- E90C-B2

- AWS A5.36: Example- E70C-6C, E70C-8M

- CSA W48-01: Carbon steel electrodes for metal cored arc welding

- EN 758

- BS EN ISO 17632

- ISO 17634

Welding Shielding Gases for Metal Cored wire

Metal cored wire requires external welding shielding gas to protect the molten weld pool like in MIG Welding.

The most common welding shielding gas for metal cored arc welding or MCAW is 75-25 Welding gas. 75-25 is mixture gas having 75% Argon and 25% CO2. Pure CO2 is rarely used with Metal core arc welding.

The benefit of using higher argon is the least loss of alloying elements such as Manganese and silicon. This is due to the fact that Argon does not react with these oxidizers in the arc.

This gives higher weld metal cleanliness, higher mechanical properties and improved weld quality which can be lost if used 100% CO2 as welding shielding gas.

Similar Posts: